Metal oxide micro nanotube capable of being used as electrode material of supercapacitor and preparation method thereof

A supercapacitor, micro-nanotube technology, applied in hybrid capacitor electrodes, oxide/hydroxide preparation, hybrid/electric double-layer capacitor manufacturing, etc. and other problems, to achieve the effect of long cycle life, strong electron transport ability and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

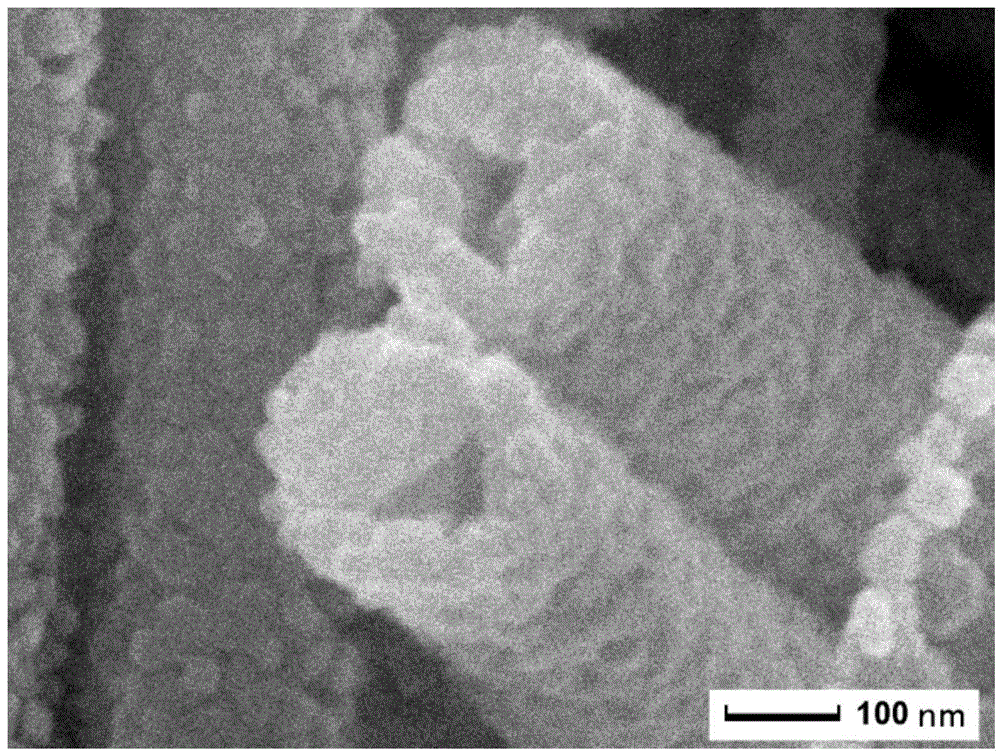

[0035] a kind of like figure 1 The NiO nanotubes that can be used as supercapacitor electrode materials according to the present invention are shown, and the metal oxide component in the NiO nanotubes is mainly NiO. The diameter of the NiO nanotube is 100nm-200nm, the length is 10μm-15μm, and the ratio of the hollow part of the NiO nanotube to the diameter of the NiO nanotube is 0.3-0.4:1.

[0036] A method for preparing the above-mentioned NiO nanotubes of the present embodiment, comprising the following steps:

[0037] (1) Add 4g of polyvinylpyrrolidone (the average molecular weight of polyvinylpyrrolidone is 630000) into 20g of dehydrated alcohol, and fully dissolve the polyvinylpyrrolidone in dehydrated alcohol by fully stirring at room temperature for 10 hours to obtain PVP solution;

[0038] (2) 2g of nickel acetate is added to the above-mentioned PVP solution, then the viscosity of the PVP solution is adjusted by adding 2g of deionized water, and the spinning solution i...

Embodiment 2

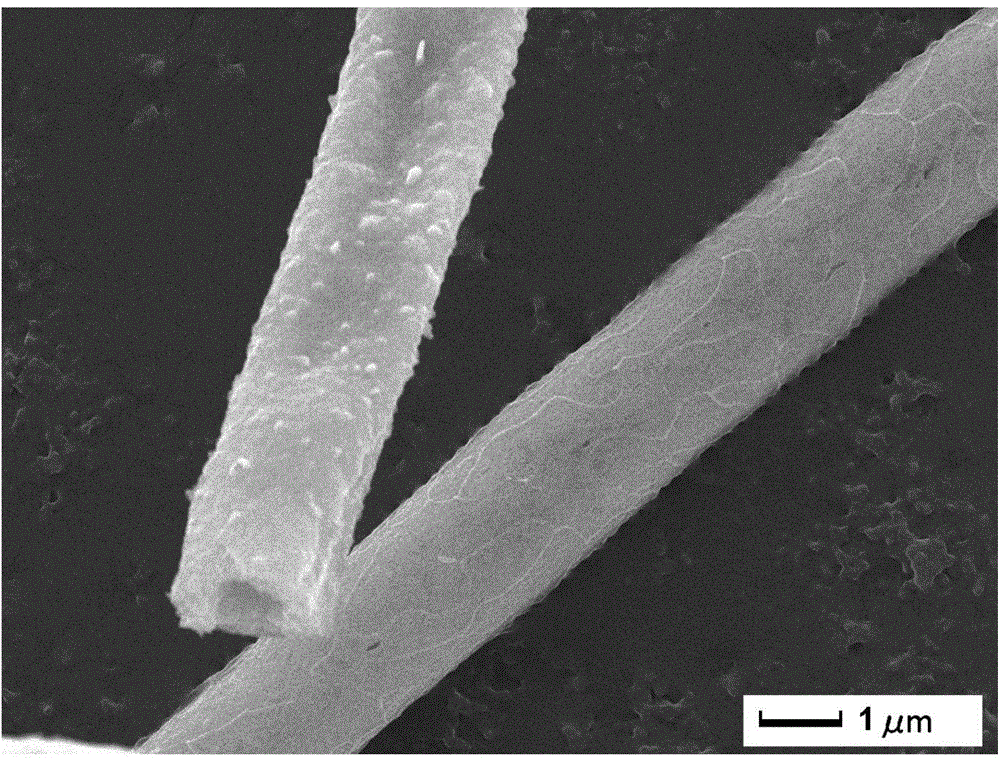

[0043] a kind of like image 3 The α-Fe that can be used for supercapacitor electrode material of the present invention shown 2 o 3 / Co 3 o 4 / NiO composite microtubes, the α-Fe 2 o 3 / Co 3 o 4 The metal oxide composition in NiO composite microtubes is mainly α-Fe 2 o 3 、Co 3 o 4 and NiO. The α-Fe 2 o 3 / Co 3 o 4 / NiO composite microtubes have a diameter of 1-2 μm and a length of 10 cm-15 cm. The α-Fe 2 o 3 / Co 3 o 4 / NiO composite microtube hollow part and α-Fe 2 o 3 / Co 3 o 4 The diameter ratio of the / NiO composite microtube is 0.6-0.7:1.

[0044] A kind of α-Fe mentioned above in this embodiment 2 o 3 / Co 3 o 4 The preparation method of / NiO composite microtube comprises the following steps:

[0045] (1) Add 4g of polyvinylpyrrolidone (the average molecular weight of polyvinylpyrrolidone is 150,000) into 18g of dehydrated alcohol, and fully dissolve the polyvinylpyrrolidone in dehydrated alcohol by fully stirring at room temperature for 10 hours ...

Embodiment 3

[0051] a kind of like Figure 4 Shown in the present invention can be used for the Co 3 o 4 Nanotubes (also known as Co 3 o 4 porous nanofibers), the Co 3 o 4 The metal oxide composition in nanotubes is mainly Co 3 o 4 . The Co 3 o 4 The diameter of the nanotube is 100-200nm, the length is 10-25μm, the Co 3 o 4 The hollow part of the nanotube and the Co 3 o 4 The ratio of the diameters of the nanotubes is 0.3-0.4:1.

[0052] A kind of Co as described above in this embodiment 3 o 4 A method for preparing nanotubes, comprising the steps of:

[0053] (1) Add 2g of polyvinylpyrrolidone (the average molecular weight of polyvinylpyrrolidone is 300,000) into 18g of dehydrated alcohol, and fully dissolve the polyvinylpyrrolidone in dehydrated alcohol by fully stirring at room temperature for 6 hours to obtain PVP solution;

[0054] (2) 1g of cobalt nitrate is added in the above-mentioned PVP solution, then the viscosity of the PVP solution is adjusted by adding 5g of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com