Preparation method of porous sodium alginate nano-fiber wound dressing

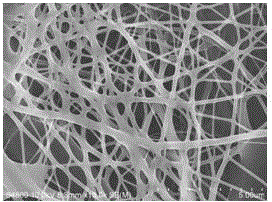

A sodium alginate and nanofiber technology, applied in the field of sanitary materials, to achieve excellent water absorption and water holding properties, high specific surface area and porosity, and the effect of promoting cell respiration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

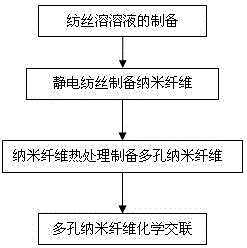

Method used

Image

Examples

Embodiment 1

[0038] Weigh 8 grams of PVA and add 100ml of deionized water, stir magnetically in a water bath at 80°C for 2 hours to dissolve the PVA to form a transparent solution, add 1 gram of sodium alginate after cooling to room temperature, stir magnetically for 1 hour to dissolve and form a transparent solution, then add 0.18 grams of carbonic acid ammonium hydrogen, stirred and dissolved to obtain spinning solution.

[0039]The spinning liquid is loaded into the liquid storage device, and the sodium alginate composite nanofiber membrane material is prepared by using the electrospinning device. Spinning conditions: voltage 30KV, solution flow rate 3ml / h, distance 10cm.

[0040] The prepared sodium alginate composite nanofiber membrane material was vacuum dried in a vacuum oven for 2 days. Then transfer to a blast drying oven, heat treatment at 50° C. for 24 hours to obtain a porous sodium alginate nanofiber membrane.

[0041] The porous sodium alginate nanofibrous membrane material...

Embodiment 2

[0043] Weigh 10 grams of gelatin and add 100ml of deionized water, stir magnetically in a water bath at 80°C for 2 hours to dissolve the gelatin to form a transparent solution, add 1 gram of sodium alginate after cooling to room temperature, stir magnetically for 1 hour to dissolve and form a transparent solution, then add 0.22 grams of carbonic acid ammonium hydrogen, stirred and dissolved to obtain spinning solution.

[0044] The spinning liquid is loaded into the liquid storage device, and the sodium alginate composite nanofiber membrane material is prepared by using the electrospinning device. Spinning conditions: voltage 30KV, solution flow rate 3ml / h, distance 10cm.

[0045] The prepared sodium alginate composite nanofiber membrane material was vacuum dried in a vacuum oven for 2 days. Then transfer to a blast drying oven, heat treatment at 50° C. for 24 hours to obtain a porous sodium alginate nanofiber membrane.

[0046] The porous sodium alginate nanofibrous membran...

Embodiment 3

[0048] Weigh 10 grams of PEO and add 100ml of deionized water, stir magnetically in a water bath at 80°C for 2 hours to dissolve the PEO to form a transparent solution, add 1 gram of sodium alginate after cooling to room temperature, stir magnetically for 1 hour to dissolve and form a transparent solution, then add 0.22 grams of carbonic acid ammonium hydrogen, stirred and dissolved to obtain spinning solution.

[0049] The spinning liquid is loaded into the liquid storage device, and the sodium alginate composite nanofiber membrane material is prepared by using the electrospinning device. Spinning conditions: voltage 30KV, solution flow rate 3ml / h, distance 10cm.

[0050] The prepared sodium alginate composite nanofiber membrane material was vacuum dried in a vacuum oven for 2 days. Then transfer to a blast drying oven, heat treatment at 50° C. for 24 hours to obtain a porous sodium alginate nanofiber membrane.

[0051] The porous sodium alginate nanofibrous membrane materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com