Mild amino acid type surfactant and preparation method and application thereof

A surfactant and amino acid-based technology, applied in the field of daily chemicals, can solve the problems of hard water resistance and high chroma, and achieve the effect of low equipment requirements, low chroma and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

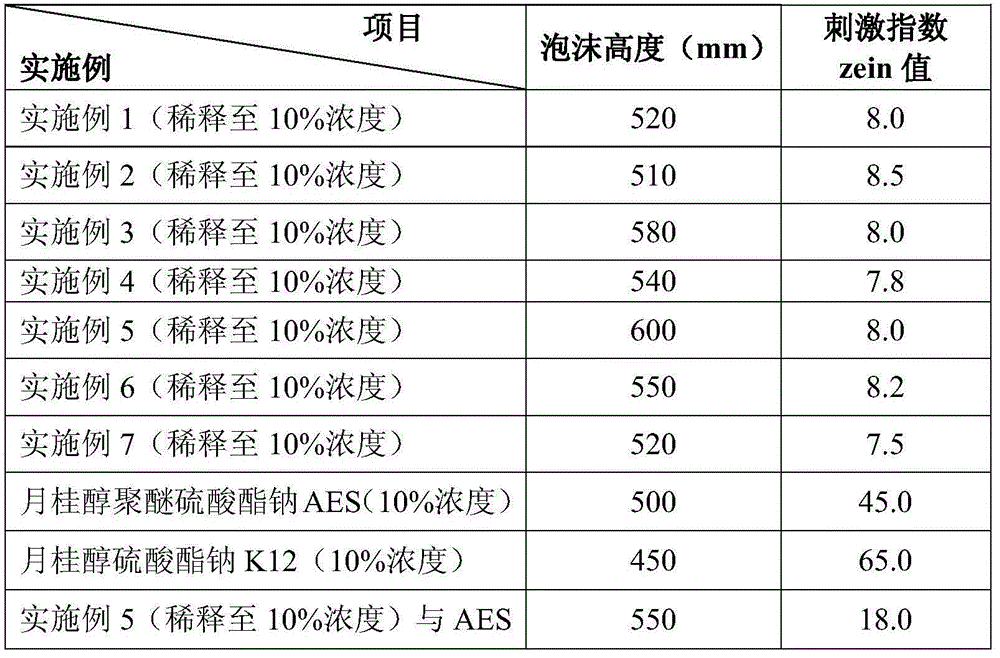

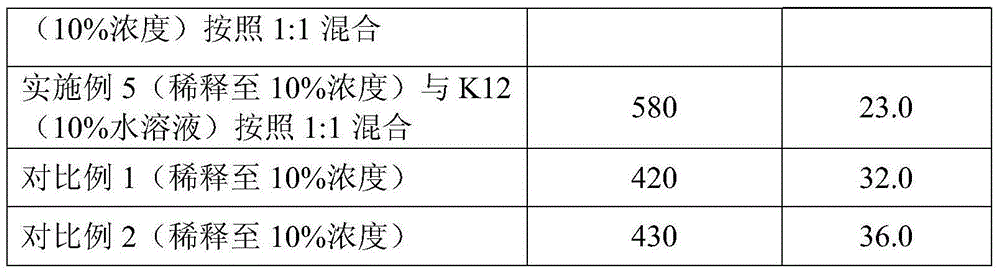

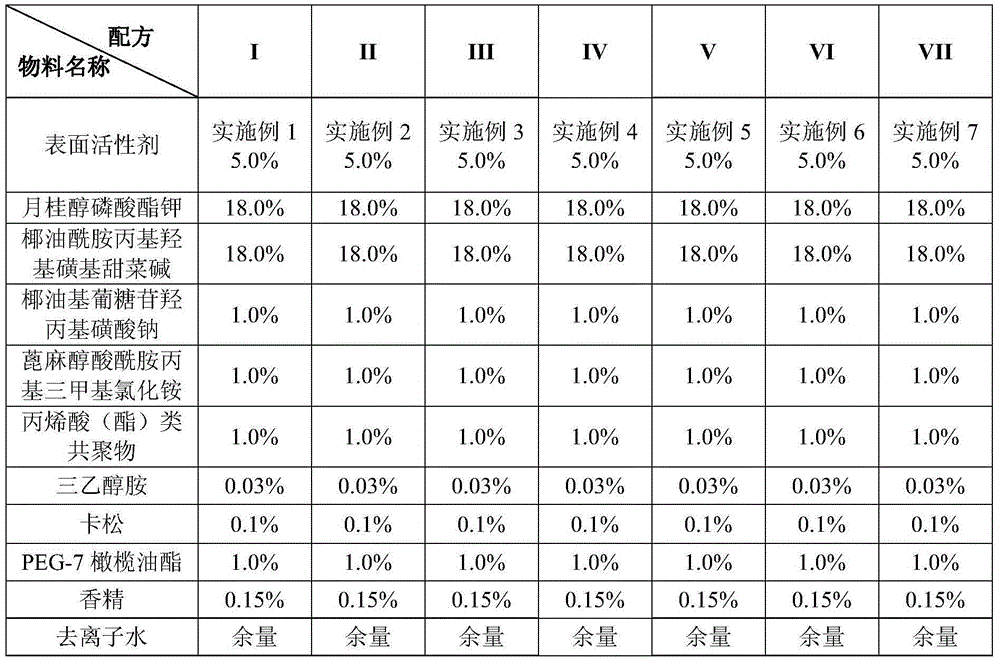

Examples

Embodiment 1

[0063] (1) Hydrolysis of oat protein polypeptide: Dissolve 30 g of oat protein polypeptide with an average molecular weight of 2000 Daltons in 100 mL of water, add 0.15 g of alkaline protease (Novozymes, 2 million units / g), and dissolve in a water bath at 45 °C to Stir at a speed of 50rpm for 3h; then adjust the pH value to 1.5 with 6mol / L hydrochloric acid, and stir at a speed of 100rpm for 3h in an 80°C water bath, during which the pH value of the system should not be higher than 2.5. Cool to room temperature, add 3g of activated carbon, stir at a speed of 50rpm for 30min, remove the activated carbon by filtration, and obtain about 125g of oat amino acid compound solution. The main component of the compound solution is a mixture of oat amino acid and oat oligopeptide. %.

[0064] Oat amino acids are mainly lysine, threonine, methionine, phenylalanine, leucine, isoleucine, valine and other amino acids, and their composition and content are determined by oat protein. For the ...

Embodiment 2

[0068] (1) Hydrolysis of oat protein polypeptide: Dissolve 35 g of oat protein polypeptide with an average molecular weight of 2450 Daltons in 120 mL of water, add 0.3 g of papain (Shanghai Jingchun, 3.5 million units / g), and heat it in a 48°C water bath at 75rpm Stir at a speed of 4 h; then adjust the pH value to 1.8 with 6 mol / L hydrochloric acid, and stir at a speed of 120 rpm for 4 h in an 85°C water bath, during which the pH value of the system is maintained not higher than 2.5. Cool to room temperature, add 4g of activated carbon, stir at a speed of 80rpm for 40min, remove the activated carbon by filtration, and obtain about 150g of oat amino acid compound solution. The main component of the compound solution is a mixture of oat amino acid and oat oligopeptide. %.

[0069] (2) Acylation of oat amino acids and oat oligopeptides: the mixture of oat amino acids and oat oligopeptides obtained in step (1) is cooled to 6°C; 0.6g catalyst ammonium p-toluenesulfonate is added, s...

Embodiment 3

[0072] (1) Hydrolysis of oat protein polypeptide: Dissolve 40 g of oat protein polypeptide with an average molecular weight of 3000 Daltons in 150 mL of water, add 0.25 g of neutral protease (Novozymes, 2 million units / g) and 0.25 g of alkaline protease ( Novozymes), stirred at a speed of 100rpm in a 50°C water bath for 6h; then adjusted the pH value to 2.0 with 6mol / L hydrochloric acid, and stirred at a speed of 150rpm in a water bath at 85°C for 6h, during which the pH value of the system was maintained not higher than 2.5. Cool to room temperature, add 3.5g of activated carbon, stir at a speed of 80rpm for 45min, remove the activated carbon by filtration, and obtain about 185g of oat amino acid compound solution, the main component of the compound solution is a mixture of oat amino acid and oat oligopeptide, and the degree of hydrolysis of oat protein polypeptide is 90%.

[0073] (2) Acylation of oat amino acids and oat oligopeptides: the mixture of oat amino acids and oat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com