Mushroom bran protein biological feed additive and preparation method thereof

A biological feed and additive technology, applied in animal feed, animal feed, application, etc., can solve the problems of insufficient nutrient utilization, poor palatability, incomplete decomposition, etc., to increase solubility and dissolution rate, promote release, and improve application. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

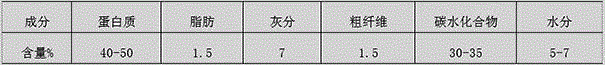

Method used

Image

Examples

Embodiment 1

[0048] (1) After picking 3-4 crops of Pleurotus eryngii mushroom chaff, select the mycelia that are white, blocky and firm, and cut off the moldy and rotten parts, and dry them in a hot air drying oven for 15 hours at 150°C to obtain dried bacteria Bran, after cooling, use airflow ultrafine pulverizer to pulverize, and the bacterium chaff powder after pulverizing passes 300 mesh sieves, obtains bacterium chaff powder;

[0049] (2) Weigh 100 kg of the fungus chaff powder prepared in (1), add 1000 kg of lime water at 40°C-45°C, pH 9-10, soak for 36 hours, adjust the pH to 4.8-5.8 with dilute sulfuric acid, add A compound enzyme consisting of 1.5 kg of cellulase, 0.75 kg of α-amylase and 0.75 kg of bromelain was incubated at 45°C for 24 hours;

[0050] (3) Squeeze the enzymatically hydrolyzed material with a wrapped press to obtain squeezed juice;

[0051] (4) Centrifuge the squeezed juice obtained in (3) with a horizontal screw centrifuge at a centrifugal speed of 7000rpm to ob...

Embodiment 2

[0058] (1) Separately harvest the chaff of Ganoderma lucidum and Tremella fungus, select the hyphae that are white, blocky and firm, and cut off the moldy and rotten parts, mix them in any proportion, and use a belt-type hot air dryer at 350°C Dried for 8 hours to obtain dry chaff, after cooling, use an airflow ultrafine pulverizer to pulverize, and the pulverized fungus powder is passed through a 200-mesh sieve to obtain mixed fungus chaff powder;

[0059] (2) Weigh 100 kg of the mixed bacterial chaff powder prepared in (1), add 2000 kg of lime water at 40°C-45°C, pH 9-10, soak for 24 hours, adjust the pH to 4.8-5.8 with dilute sulfuric acid, Add a compound enzyme consisting of 2 kg of cellulase, 1 kg of α-amylase and 1 kg of bromelain, and incubate at 40°C for 36 hours;

[0060] (3) Squeeze the enzymatically hydrolyzed material with a wrapped press to obtain squeezed juice;

[0061] (4) Centrifuge the squeezed juice obtained in (3) with a horizontal screw centrifuge at a ce...

Embodiment 3

[0068] (1) Take the chaff of Pleurotus ostreatus after harvesting 2-3 stubbles, select the hyphae that are white, blocky and firm, and cut off the moldy and rotten parts, and dry them in a hot air drying oven for 12 hours at 200°C to obtain dried mushrooms Bran, after cooling, use the airflow ultrafine pulverizer to pulverize, and the bacterium chaff powder after pulverizing crosses 250 mesh sieves, obtains the bacterium chaff powder;

[0069] (2) Weigh 100 kg of the fungus chaff powder prepared in (1), add 1500 kg of lime water at 40°C-45°C, pH 9-10, soak for 30 hours, adjust the pH to 4.8-5.8 with dilute sulfuric acid, add A compound enzyme consisting of 2 kg of cellulase, 0.5 kg of α-amylase and 0.5 kg of bromelain was incubated at 42°C for 30 hours;

[0070] (3) Squeeze the enzymatically hydrolyzed material with a wrapped press to obtain squeezed juice;

[0071] (4) Centrifuge the squeezed juice obtained in (3) with a horizontal screw centrifuge at a centrifugal speed of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com