A novel method of preparing agarose magnetic microspheres and uses of the agarose magnetic microspheres in separation and purification of an IgG antibody

A technology of agarose microspheres and magnetic microspheres, applied in other chemical processes, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of small specific surface area, low separation and purification, low coating efficiency, etc., and achieve particle size distribution. Uniform, not easy to agglomerate and agglomerate, easy to operate and save time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

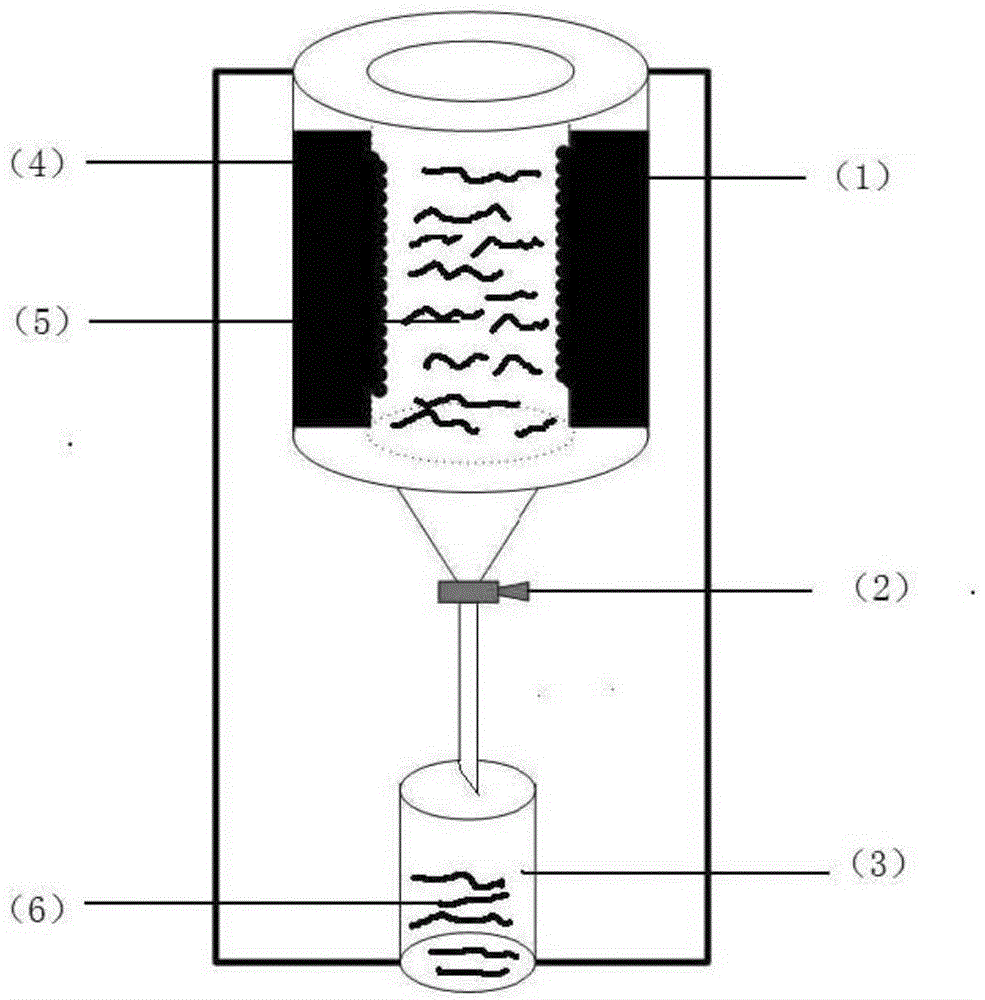

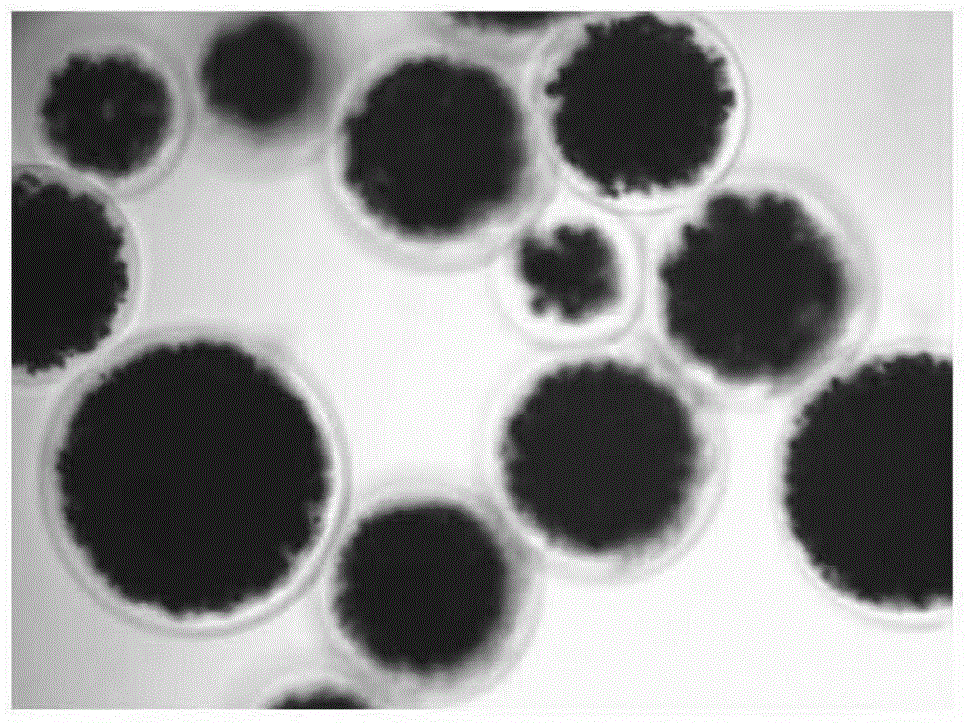

[0067] Embodiment 1: Preparation of agarose magnetic microspheres

[0068] (i) Preparation of non-magnetic core agarose microspheres:

[0069] Add 2.0 g of agarose to 100 ml of ultrapure water and heat at 100°C to prepare the agarose aqueous phase W. Subsequently, 8.0 g of emulsifier Span 80 was added to 180 ml of liquid paraffin and 40 ml of petroleum ether, and fully dispersed to prepare oil phase O. The oil phase O was heated at a constant temperature of 80°C, mechanically stirred at 400rpm, and the water phase was quickly transferred in, and reacted for 3h. The ice-water bath was cooled rapidly to 15°C.

[0070] (ii) Activation and cross-linking of non-magnetic core agarose microspheres:

[0071]Take 5g of microspheres, add 7.5ml of 0.8mol / L NaOH, 0.01g of sodium borohydride, shake at 25°C and 400rpm for 30min. To the solution thus prepared were added 7.5 ml of dimethyl sulfoxide and 3.75 ml of epichlorohydrin. React at a constant temperature of 30°C and 400rpm for 20...

Embodiment 2

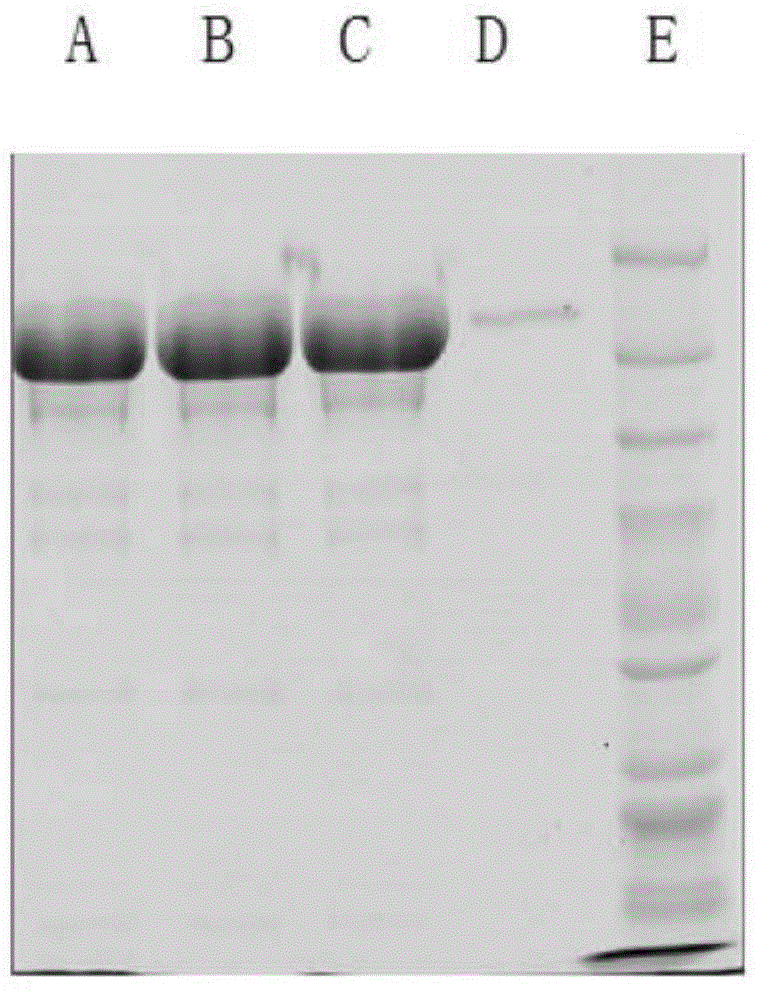

[0080] Embodiment 2: Magnetic separation and purification of IgG monoclonal antibody

[0081] Take 1ml of the prepared agarose magnetic microspheres, after fully washing and balancing with PBS buffer, add 10ml of lysate of cells expressing IgG monoclonal antibody diluted to a certain concentration with buffer, react with slow shaking for 1 hour, and transfer the liquid to Into the magnetic separation and purification device, adsorb and fix the magnetic microspheres, remove the separation device and discard the reaction solution, then wash with 10ml PBS buffer solution for 3 times, add 4ml 0.1M glycine-hydrochloric acid buffer solution, and slowly shake for 1 hour for dissociation The adsorbed antibodies are then transferred to the magnetic separation and purification device, the magnetic microspheres are adsorbed, and the dissociation solution is collected.

Embodiment 3

[0082] Embodiment 3: the elution recovery of magnetic microsphere

[0083] After collecting the dissociation solution, add PBS buffer solution to the adsorption magnetic balls of Example 2 and wash them several times, balance the magnetic microspheres, discard the cleaning solution, and store the washed microspheres in 20% ethanol aqueous solution at 4°C , can be reused more than 20 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com