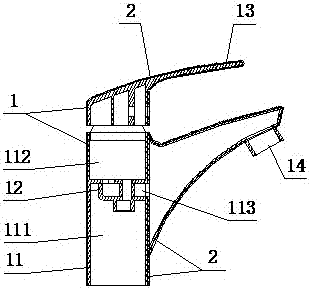

A multifunctional faucet and its manufacturing method

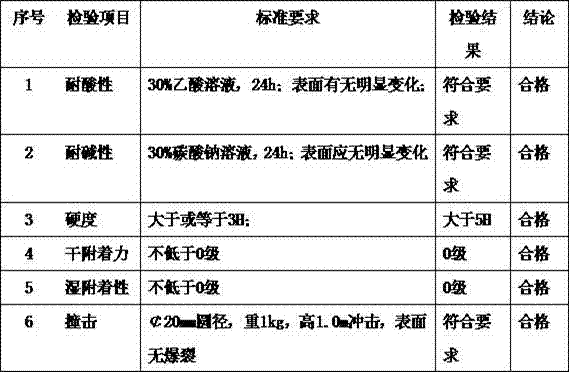

A faucet, multi-functional technology, applied in the direction of coating, valve details, valve housing structure, etc., can solve the problems of faucets that are easy to cause corrosion, toilets that are unsightly, and water performance, etc., to achieve strong adhesion, easy to popularize and promote, The effect of ceramic coating stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Proportion by weight

[0083] A, the preparation operation steps of coating 2 batch materials are as follows:

[0084] Ⅰ. Preparation of base material

[0085] (1) Take 9.0 parts of porcelain powder, 1.5 parts of quartz powder, and 3.0 parts of zirconium dioxide, mix them in a blender to form a mixture, and set aside;

[0086] ⑵. The above-mentioned spare mixture is placed in a sintering furnace, reacted and sintered at a high temperature of 1300 °C for 1.5 hours, cooled, and set aside;

[0087] (3) Put the sintered spare parts in the grinding equipment, pulverize and finely grind them into a mixed base material with a particle size of 560 mesh;

[0088] ⑷, the mixed base material is dried in the drying equipment, and the powder is used for standby;

[0089] Ⅱ. Stirring of polytetrafluoroethylene dispersion

[0090] ⑸. Take 107.1 parts of polytetrafluoroethylene dispersion in a mixer and stir fully;

[0091] 6. Add 1.5 parts of mixed base material to the above poly...

Embodiment 2

[0139] The distribution ratio of components is calculated by parts by weight

[0140] A, the preparation operation steps of coating 2 batch materials are as follows:

[0141] Ⅰ. Preparation of base material

[0142] (1) Take 10.0 parts of porcelain powder, 5.0 parts of quartz powder, and 10.0 parts of zirconium dioxide, mix them in a blender to form a mixture, and set aside;

[0143] (2) The above-mentioned spare mixture is placed in a sintering furnace, reacted at a high temperature of 1350°C, sintered for 2.0 hours, cooled, and set aside;

[0144] (3) Put the sintered spare parts in the grinding equipment, pulverize and finely grind them into a mixed base material with a particle size of 600 mesh;

[0145] ⑷, the mixed base material is dried in the drying equipment, and the powder is used for standby;

[0146] Ⅱ. Stirring of polytetrafluoroethylene dispersion

[0147] ⑸. Take 421.5 parts of polytetrafluoroethylene dispersion liquid in the mixer and stir fully;

[0148] ...

Embodiment 3

[0196] The distribution ratio of components is calculated by parts by weight

[0197] A, the preparation operation steps of coating 2 batch materials are as follows:

[0198] Ⅰ. Preparation of base material

[0199] (1) Take 48.0 parts of porcelain powder, 24.0 parts of quartz powder, and 40.0 parts of zirconium dioxide, mix them in a blender to form a mixture, and set aside;

[0200] ⑵. The above spare mixture is placed in a sintering furnace, reacted and sintered at a high temperature of 1250°C for 1.0h, cooled, and set aside;

[0201] (3) Put the sintered spare parts in the grinding equipment, pulverize and finely grind it into a mixed base material with a particle size of 520 mesh;

[0202] ⑷, the mixed base material is dried in the drying equipment, and the powder is used for standby;

[0203] Ⅱ. Stirring of polytetrafluoroethylene dispersion

[0204] ⑸. Take 460.8 parts of polytetrafluoroethylene dispersion in the mixer and stir fully;

[0205] 6. Add 15.68 parts of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com