Conductive paste for laser etching, conductive thin film, and conductive laminate

A conductive thin film, laser etching technology, which is applied to conductive materials dispersed in non-conductive inorganic materials, conductive layers on insulating carriers, and removal of conductive materials by light, which can solve problems such as complicated processes and large environmental loads. , to achieve the effect of reducing laser output, ensuring continuity, and excellent suitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0092] In order to further explain the present invention in detail, the following examples and comparative examples are given, but the present invention is not limited by the examples. In addition, each measured value described in an Example and a comparative example was measured by the following method.

[0093] 1. Number average molecular weight

[0094] The sample resin was dissolved in tetrahydrofuran so that the resin concentration became about 0.5% by weight, and filtered using a polytetrafluoroethylene membrane filter with a pore size of 0.5 μm to prepare a GPC measurement sample. Tetrahydrofuran was used as the mobile phase, Gel Permeation Chromatography (GPC) Prominence (trade name) manufactured by Shimadzu Corporation was used, and a differential refractive index detector (RI meter) was used as the detector. GPC measurement of the resin sample was carried out per minute. In addition, the number-average molecular weight was calculated by omitting the part correspond...

manufacture example

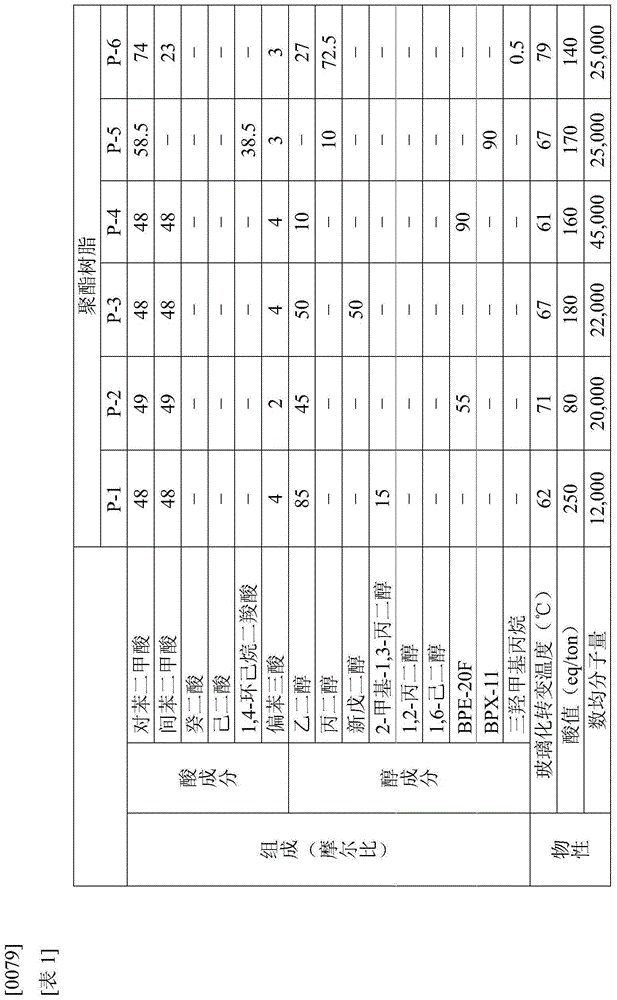

[0144] Production example of polyester resin P-1

[0145] Put 700 parts of terephthalic acid, 700 parts of isophthalic acid, 16.9 parts of trimellitic anhydride, 983 parts of ethylene glycol, and 2-methyl-1,3- 154 parts of propylene glycol were heated up from 160° C. to 230° C. over 3 hours under a pressure of 2 atmospheres in a nitrogen atmosphere to perform an esterification reaction. After releasing the pressure, put 0.92 parts of tetrabutyl titanate, and then slowly reduce the pressure in the reaction system to 5 mmHg in 20 minutes, and then carry out 40 minutes at 260°C under a vacuum of 0.3 mmHg or less. polycondensation reaction. Then, under nitrogen flow, it cooled to 220 degreeC, and 50.6 parts of trimellitic anhydrides were injected|thrown-in, and it reacted for 30 minutes, and polyester resin was obtained. Table 1 shows the composition and physical properties of the obtained copolyester resin P-1.

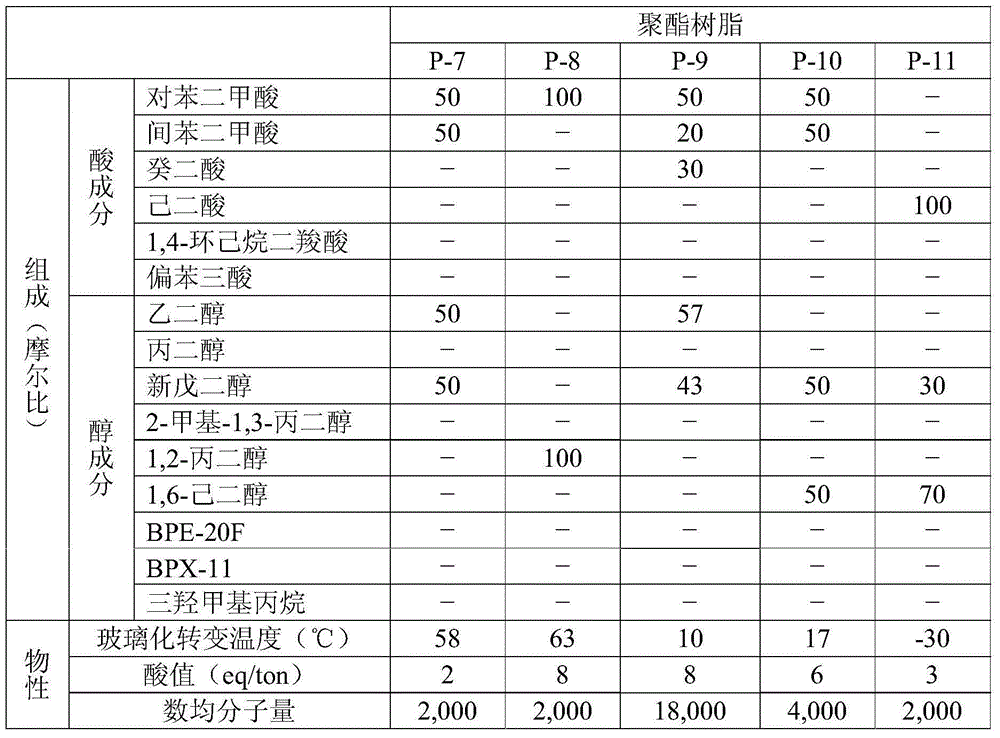

[0146] Production example of polyester resin P-2 to P-11

[014...

Embodiment 1

[0164] Dissolving polyester resin P-1 in EDGAC so that the solid content concentration is 35% by mass is 2,860 parts (1,000 parts in terms of solid content), 7,888 parts of flaky silver powder 1, and 71 parts of Kyoei as a leveling agent Mix MK Conc manufactured by Sha Kagaku Co., Ltd., 30 parts of Disperbyk 130 manufactured by BYK Chemical Japan Co., Ltd. as a dispersant, and 300 parts of EDGAC as a solvent, and disperse three times in a refrigerated three-roll mixer . After that, the obtained conductive paste was printed on a predetermined pattern, and then dried at 120° C. for 30 minutes to obtain a conductive film. Basic physical properties were measured using this conductive thin film, and then laser etching processing was examined. Table 4 shows the evaluation results of the paste, paste coating film, and laser etching processability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Line width | aaaaa | aaaaa |

| Line width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com