Premix feed capable of improving quality of mink fur and increasing feed utilization rate and preparation method of premix feed

A technology of pre-mixed feed and mixed feed, applied in the direction of animal feed, animal feed, application, etc., can solve the problems of not giving full play to the nutritional value of feed, saving feed cost, not involving, etc., to improve the quality of mink fur and breeding efficiency, promote The effect of fur growth, reducing the incidence of mink disease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

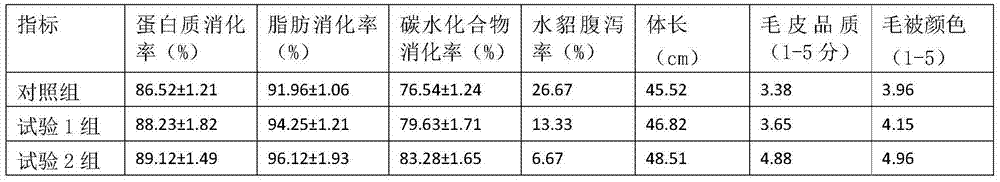

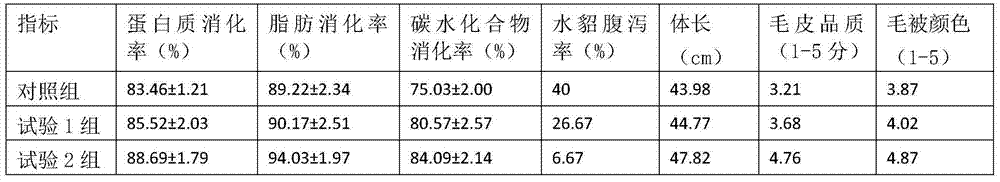

Examples

Embodiment 1

[0017] The premixed feed proposed by the present invention includes the following components. Based on one kilogram of mixed feed, the distribution ratio of its raw material components is: 275g of corn gluten powder, 18g of compound vitamin B, 26g of compound enzyme preparation, 270,000 IU of vitamin A, 12g of vitamin C, vitamin E 2200IU, Vitamin D 3 60,000 IU, vitamin K 3 0.8g, DL-methionine 15g, L-lysine 18g, L-arginine 12g, D-biotin 0.6g, choline chloride 60g, methionine chelated iron 22g, methionine chelated copper 12g, methionine chelated Manganese 32g, methionine chelated zinc 26g, sodium selenite 5g, cobalt acetate 6g, potassium iodide 5g, probiotics 12g, calcium pantothenate 4g, nicotinamide 4g, folic acid 0.8g, calcium dihydrogen phosphate 135g, sodium chloride 30g, puffed Corn flour 265g.

Embodiment 2

[0019] The premixed feed proposed by the present invention includes the following components, based on one kilogram of mixed feed, the distribution ratio of its raw material components is: 260g of corn gluten powder, 23g of compound vitamin B, 27g of compound enzyme preparation, 250,000 IU of vitamin A, 15g of vitamin C, vitamin E 2000IU, Vitamin D 3 50,000 IU, Vitamin K 3 1g, DL-methionine 20g, L-lysine 19g, L-arginine 10g, D-biotin 0.5g, choline chloride 60g, methionine chelated iron 25g, methionine chelated copper 13g, methionine chelated manganese 34g, methionine chelated zinc 30g, sodium selenite 10g, cobalt acetate 5g, potassium iodide 8g, probiotics 10g, calcium pantothenate 5g, nicotinamide 3g, folic acid 0.5g, calcium dihydrogen phosphate 145g, sodium chloride 33g, puffed corn Powder 240g.

Embodiment 3

[0021] The premixed feed proposed by the present invention includes the following components. Based on one kilogram of mixed feed, the distribution ratio of its raw material components is: 250g of corn gluten powder, 20g of compound vitamin B, 28g of compound enzyme preparation, 280,000 IU of vitamin A, 14g of vitamin C, and E 2300IU, Vitamin D 3 70,000 IU, Vitamin K 31.1g, DL-methionine 18g, L-lysine 20g, L-arginine 13g, D-biotin 0.8g, choline chloride 60g, methionine chelated iron 26g, methionine chelated copper 10g, methionine chelated Manganese 33g, methionine chelated zinc 28g, sodium selenite 6g, cobalt acetate 8g, potassium iodide 6g, probiotics 15g, calcium pantothenate 6g, nicotinamide 5g, folic acid 0.7g, calcium dihydrogen phosphate 140g, sodium chloride 32g, puffed Corn flour 255g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com