Catalyst used in synthesizing isopropanethiol from propylene and hydrogen sulfide

A technology of isopropyl mercaptan and catalyst, which is applied in the chemical industry, can solve the problems of extremely high requirements for equipment corrosion protection, low isopropyl mercaptan yield, and low isopropyl mercaptan yield, so as to reduce operating costs and facilitate industrial The effect of amplification, high activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

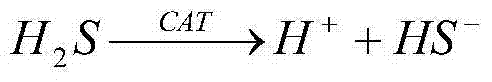

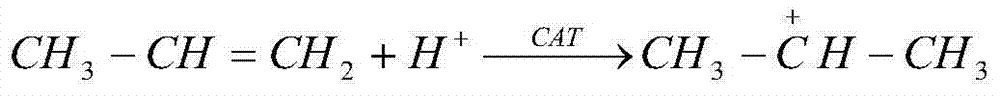

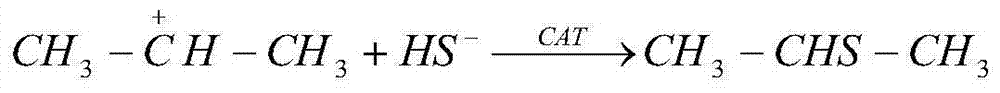

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Take Zibo Haoye Industry and Trade Co., Ltd.’s ZSM-5 molecular sieve with a molar ratio of alumina dry glue to silicon aluminum of 10 and a grain size of 1 μm, a binder (15% aqueous nitric acid solution) and an auxiliary agent (Xiangshui Hongrun safflower powder) and mix evenly, control the ZSM-5 molecular sieve content in the carrier to 5%, add appropriate amount of deionized water and mix evenly, extrude into a 2-3 cylindrical shape, dry at 120°C for 4 hours, and roast at 700°C for 3 hours , to obtain vector S-1. The water absorption of carrier S-1 was measured to be 80%.

[0043] Dissolve 3.96g of cobalt nitrate and 1.23g of ammonium heptamolybdate in deionized water, dilute to 78.4mL and mix well. 98g of carrier S-1 was impregnated with the above solution, left to dry at room temperature for 24 hours, dried at 120°C for 4 hours, and calcined at 400°C for 3 hours in an air atmosphere to obtain catalyst C-1.

Embodiment 2

[0045] Carrier S-1 was prepared according to the method in Example 1.

[0046] Add 4.06g of 85% phosphoric acid in deionized water and mix well, add 5.36g of basic nickel carbonate and 7.00g of molybdenum trioxide into the above solution, heat and stir to fully dissolve, and after cooling to room temperature, dilute it to 70.0mL . 87.5 g of carrier S-1 was impregnated with the above solution, left to dry at room temperature for 24 hours, dried at 120°C for 4 hours, and calcined at 450°C for 4 hours in an air atmosphere to obtain catalyst C-2.

Embodiment 3

[0048] Take Zibo Haoye Industry and Trade Co., Ltd. ZSM-5 molecular sieve with a ratio of alumina dry glue to silicon aluminum of 20 and a grain size of 5 μm, a binder (15% aqueous solution of nitric acid) and an additive (Xiangshui Hongrun’s Cylindrica powder) mixed evenly, the ZSM-5 molecular sieve content in the carrier was controlled to be 5%, an appropriate amount of deionized water was added to mix evenly, extruded into a 2-3 cylindrical shape, dried at 120°C for 4 hours, and roasted at 700°C for 3 hours, Vector S-2 was obtained. The water absorption of the carrier S-2 was measured to be 82%.

[0049] Add 3.25g of 85% phosphoric acid in deionized water and mix well, add 3.58g of basic nickel carbonate and 5.00g of molybdenum trioxide into the above solution, heat and stir to fully dissolve, and after cooling to room temperature, dilute it to 74.6mL . 91 g of carrier S-2 was impregnated with the above solution, left to dry at room temperature for 24 hours, dried at 120°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com