Preparation method for hydrophobic nanometer modified resin composite paint used for LED base plate

A LED substrate, hydrophobic nanotechnology, applied in the field of coatings, can solve the problems of LED failure, no thermal conductivity, small thermal conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is further described below by example.

[0014] The preparation method of the nano-modified resin composite coating that is used for LED substrate among the present invention, comprises the steps:

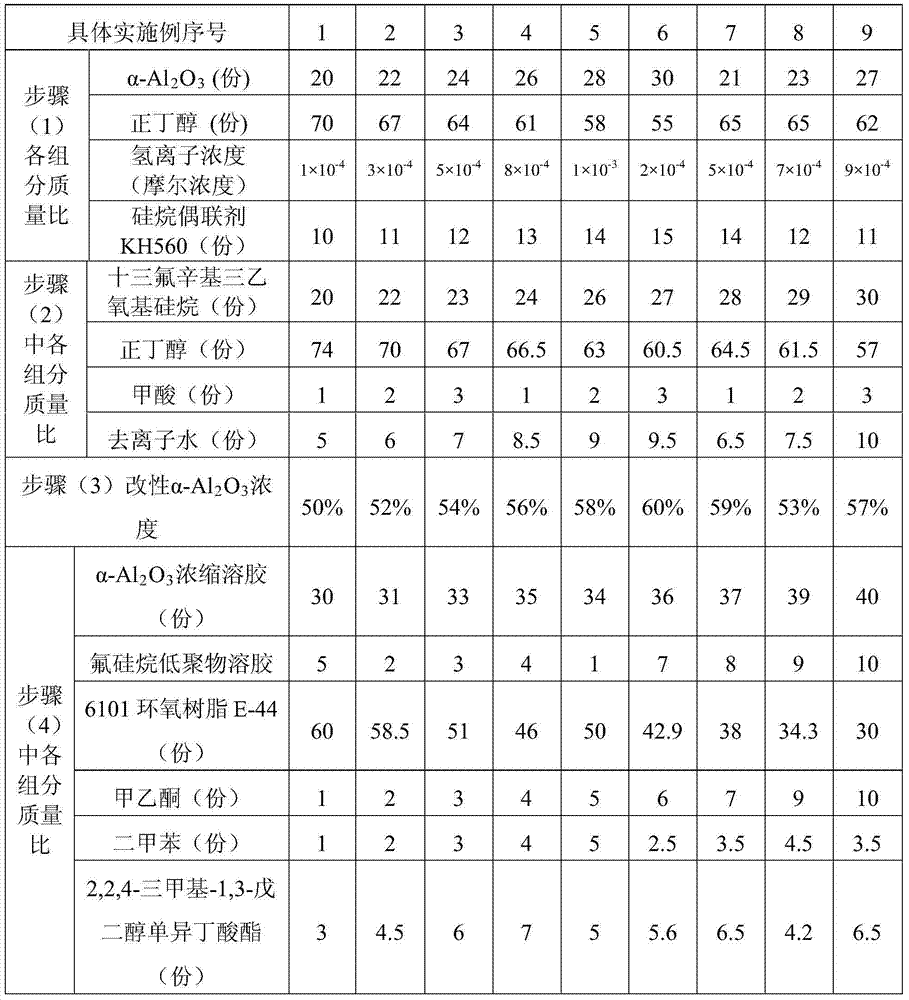

[0015] (1) At a stirring rate of 800 to 1000r / min, 20 to 30 parts by mass of nano-α-Al 2 o 3 and 55-70 parts by mass of butanol are added to the disperser to disperse evenly; then HCl is added to adjust the concentration of hydrogen ions in the system at 10 -3 ~10 -4 M, then add 10-15 parts by mass of silane coupling agent KH560, and age at 50°C for 24 hours to obtain nano-α-Al surface-modified by KH560 2 o 3 Sol.

[0016] (2) Add 20-30 parts by mass of tridecafluorooctyltriethoxysilane to 57-74 parts by mass of n-butanol, add 1-3 parts by mass of formic acid and mix well, add 5-10 parts by mass of deionized water, Aged at 60°C for 48 hours to obtain a fluorosilane oligomer sol.

[0017] (3) Utilize the L-H type rotary evaporator to modify the α-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com