Ultraviolet cured rare earth polymer material and preparation method thereof

A polymer material, ultraviolet light technology, applied in chemical instruments and methods, luminescent coatings, organic chemistry, etc., can solve problems such as difficulty in adapting to environmental protection requirements, poor photothermal stability, etc., to achieve shortened curing time, low cost, synthetic simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

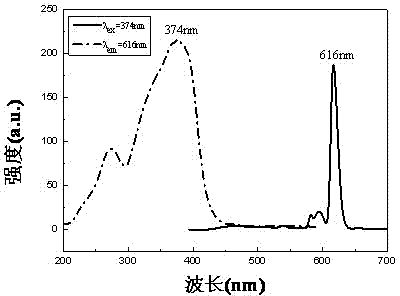

Image

Examples

Embodiment 1

[0023] A method for preparing an ultraviolet-cured rare earth polymer material, characterized in that:

[0024] (1) Preparation of rare earth acrylic acid complex, weighing europium oxide, dibenzoylmethane, and acrylic acid in a molar ratio of 1:4:6, wherein europium oxide is 2 mmol;

[0025] Take 5ml of hydrochloric acid to dissolve europium oxide into a colorless transparent solution, heat until the solution is completely evaporated to dryness, and obtain a white powdery europium chloride. After the white solid is cooled, add an appropriate amount of absolute ethanol to dissolve it to obtain anhydrous transparent chlorine Europium chloride absolute ethanol solution;

[0026] Weigh 8-20mmol of acrylic acid and pour it into a three-necked flask equipped with a condenser tube and a thermometer, stir and adjust the temperature to 30°C, then add europium chloride anhydrous ethanol solution dropwise into the three-necked flask, and adjust the reaction with sodium hydroxide The pH...

Embodiment 2

[0032] A method for preparing an ultraviolet-cured rare earth polymer material, characterized in that:

[0033] (1) Preparation of rare earth acrylic acid complex, weighing europium oxide, dibenzoylmethane, and acrylic acid in a molar ratio of 1:4:6, wherein europium oxide is 2 mmol;

[0034] Take 7ml of hydrochloric acid to dissolve europium oxide to form a colorless transparent solution, heat until the solution is completely evaporated to dryness, and obtain a white powdery europium chloride. After the white solid is cooled, add an appropriate amount of absolute ethanol to dissolve to obtain anhydrous transparent chlorine Europium chloride absolute ethanol solution;

[0035] Weigh 12mmol of acrylic acid and pour it into a three-necked flask equipped with a condenser tube and a thermometer, stir and adjust the temperature to 50°C, then add the europium chloride anhydrous ethanol solution dropwise into the three-necked flask, and adjust the reaction solution with sodium hydrox...

Embodiment 3

[0041] A method for preparing an ultraviolet-cured rare earth polymer material, characterized in that:

[0042] (1) Preparation of rare earth acrylic acid complex, weighing europium oxide, dibenzoylmethane, and acrylic acid in a molar ratio of 1:4:6, wherein europium oxide is 2 mmol;

[0043]Take 10ml of hydrochloric acid to dissolve europium oxide into a colorless transparent solution, heat until the solution is completely evaporated to dryness, and obtain a white powdery europium chloride. After the white solid is cooled, add an appropriate amount of absolute ethanol to dissolve it to obtain anhydrous transparent chlorine Europium chloride absolute ethanol solution;

[0044] Weigh 12mmol of acrylic acid and pour it into a three-necked flask equipped with a condenser tube and a thermometer, stir and adjust the temperature to 70°C, then add the europium chloride anhydrous ethanol solution dropwise into the three-necked flask, and adjust the reaction solution with sodium hydrox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com