Preparation method of composite lithium titanate material

A technology of compounding lithium titanate and slurry, which is applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of doping, reducing discharge capacity and first charge and discharge efficiency, and achieves simple process flow and good battery life. Chemical properties, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

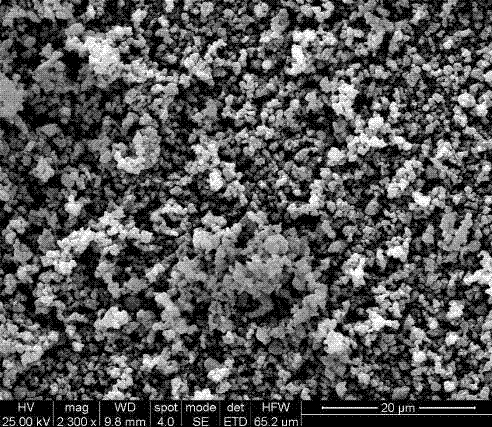

Image

Examples

Embodiment 1

[0025] Disperse 2mol of lithium carbonate, 4.9mol of anatase titanium dioxide and 0.1mol of tetra-n-propyl zirconate (zirconate coupling agent) in ethanol, the ratio of solid to organic solvent is 1:1.5, on a planetary ball mill Grind and disperse for 5 hours to prepare the lithium titanate precursor mixture, dry it in a vacuum oven at 100°C, grind and crush the precursor fine powder uniformly, put the dispersed powder into a crucible, and place it in a nitrogen atmosphere to protect the high temperature furnace In the process, the temperature was raised to 700 ° C, and after 12 hours of heat preservation, it was naturally cooled to room temperature, taken out, crushed and sieved to obtain the composite lithium titanate material Li 4 Zr 0.1 Ti 4.9 o 12 / C y (0≤y≤0.05).

Embodiment 2

[0027] Disperse 4.2mol lithium nitrate, 5mol rutile titanium dioxide and 0.05mol chromium chloride methacrylate (chromium complex coupling agent) in ethanol, the ratio of solid to organic solvent is 1:2, and grind on a planetary ball mill Disperse for 10 hours to prepare the lithium titanate precursor mixture, dry it at 120°C, grind and crush it to obtain a uniformly dispersed precursor fine powder, put the dispersed powder into a crucible, and place it in a nitrogen mixed with 10% hydrogen atmosphere to protect the high temperature furnace In the process, the temperature was raised to 950 ° C, and after 10 hours of heat preservation, it was naturally cooled to room temperature, taken out, crushed and sieved to obtain the composite lithium titanate material Li 4 Gr 0.05 Ti 4.95 o 12 / C y (0≤y≤0.05).

Embodiment 3

[0029] Disperse 4 mol of lithium hydroxide, 5 mol of anatase titanium dioxide and 0.1 mol of methacryloxy functional zirconium aluminate (aluminum zirconate coupling agent) in acetone, the ratio of solid to organic solvent is 1:1.7, in the planet Grinding and dispersing on a type ball mill for 10 hours to prepare a lithium titanate precursor mixture, drying it in a vacuum oven at 100°C, grinding and crushing to obtain a uniformly dispersed precursor fine powder, and putting the dispersed powder into a crucible and placing it in a nitrogen atmosphere In a protected high-temperature furnace, raise the temperature to 600°C, keep it warm for 5 hours, cool it naturally to room temperature, take it out, crush it, and sieve it, then heat it up to 900°C, keep it warm for 10 hours, cool it down to room temperature naturally, take it out, crush it, and sieve it After separation, the composite lithium titanate material Li 4 m 0.1 Ti 4.9 o 12 / C y (M=Al, Zr; 0≤y≤0.05).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com