Energy-saving, environmental-protection and resourced pulping method of plant fibers

A technology of plant fiber and resource utilization, which is applied in the fields of energy saving, environmental protection, and resource utilization of plant fiber, which can solve the problems of lack of comprehensive utilization of waste and wastewater, achieve high bonding strength, reduce consumption, and improve pulp quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

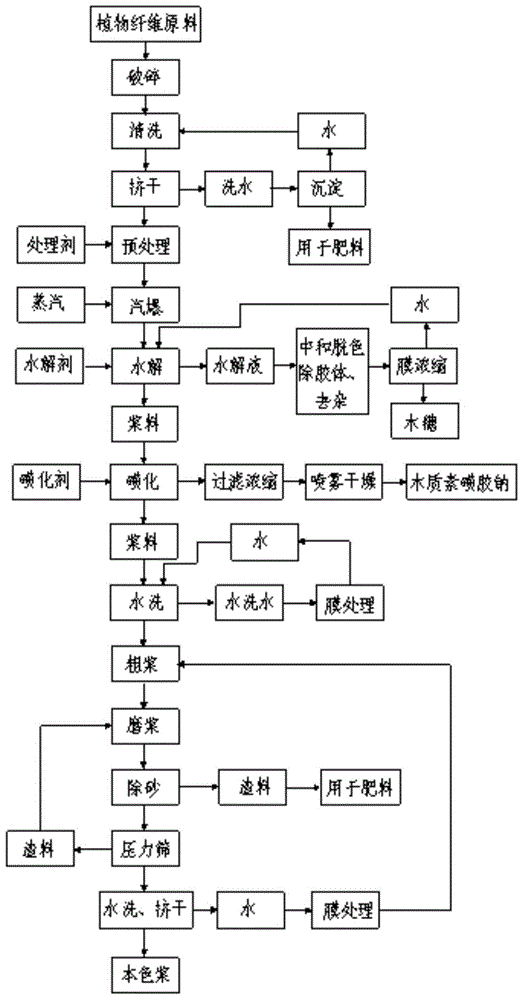

[0036] In this embodiment, rice straw is used as the plant fiber raw material, and its pulping method is as follows: figure 1 shown.

[0037] The straw is cut by a grass cutter, and the length of the raw material after cutting is 2-4cm; after washing and dedusting, it is squeezed dry, and the extruded washing water is further used for washing and dedusting of plant fiber raw materials after sedimentation treatment, and the sediment of the washing water is used as fertilizer.

[0038] Put the cut, washed, dedusted and squeezed straw material into the spiral preprocessor at a flow rate of 1000Kg / h, and spray 1Kg of HZ additive and 300Kg of dilute lye with a concentration of 4% at the same time. The treatment temperature is 90°C and the treatment time is 30 minute. HZ composite additive is a compound of fatty alcohol polyoxyethylene ether, alkylphenol polyoxyethylene ether and sodium alkylbenzene sulfonate, and its weight ratio is 3:2:1.

[0039] The water content of the straw ...

Embodiment 2

[0046] The present embodiment takes Salix salix as the plant fiber raw material, and its pulping method is as follows: figure 1 shown.

[0047] Salix salix is cut with a crusher and thinned at the same time. After cutting, the length of the raw material is 2 to 4 cm. Squeeze dry after washing and dedusting, and the extruded washing water will continue to be used for washing and dedusting of plant fiber raw materials after precipitation treatment, and the sediment of washing water will be used as fertilizer.

[0048] Put the Salix salix material after cutting, washing, dedusting and squeezing into the spiral preprocessor at a flow rate of 1500Kg / h, and spray 3Kg of HZ additive and 400Kg of dilute lye with a concentration of 5% at the same time, the treatment temperature is 20°C, and the treatment time is 60 minutes. HZ composite additive is a compound of fatty alcohol polyoxyethylene ether, alkylphenol polyoxyethylene ether and sodium alkylbenzene sulfonate, and its weight ...

Embodiment 3

[0056] In this embodiment, cotton stalks are used as plant fiber raw materials, and the pulping method is as follows: figure 1 shown.

[0057] The cotton stalks are cut by a crusher, and the length of the raw material after cutting is 2 to 4 cm. Squeeze dry after washing and dedusting, and the extruded washing water will continue to be used for washing and dedusting of plant fiber raw materials after precipitation treatment, and the sediment of washing water will be used as fertilizer.

[0058] Put the cotton stalk material after cutting, washing, dedusting and squeezing into the spiral preprocessor at a flow rate of 1500Kg / h, and spray 2Kg of HZ additive and 500Kg of dilute lye with a concentration of 3% at the same time, the treatment temperature is 20°C, and the treatment time is 60 minutes. HZ composite additive is a compound of fatty alcohol polyoxyethylene ether, alkylphenol polyoxyethylene ether and sodium alkylbenzene sulfonate, and its weight ratio is 3:5:2.

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com