Sunflower disk composite feed and preparation method thereof

A sunflower tray and feed technology, applied in animal feed, animal feed, applications, etc., can solve the problems of difficult silage, difficult to be widely used, and high processing cost, and achieve the effects of good palatability, simple equipment, and high nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

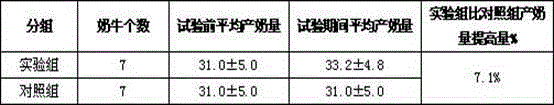

Image

Examples

Embodiment 1

[0037] Embodiment one: the preparation of sunflower dish feed

[0038] The sunflower plate compound feed is specifically prepared through the following process, % is calculated by weight percentage, and the specific preparation method steps are as follows:

[0039] (1) Pretreatment of raw materials: 40%-50% of sunflower discs, 20%-30% of Chamagu leaves, 10%-20% of soybean meal and 10%-20% of stevia leaves, mixed and crushed in proportion, in sunflower Spray an appropriate amount of water on the pan composite powder, stir it evenly with a mixer, and leave it overnight. After one day of absorption and evaporation, the water content of the sunflower pan composite powder is 40%-60%;

[0040] (2) Activation and cultivation of strains: Pseudomonas aeruginosa, Streptomyces albicans, Bacillus licheniformis, Flavobacterium, Bacillus jelly-like and Bacillus megaterium were respectively activated and cultured on the inclined surface of the test tube, and activated on the inclined surfa...

Embodiment 2

[0051] Embodiment two: the preparation of sunflower tray feed

[0052] (1) Pretreatment of materials: Weigh 400Kg of sunflower discs, 100Kg of purslane, 300Kg of Chamagus leaves, and 200Kg of stevia leaves, crush and mix them to obtain 1 ton of sunflower disc composite materials. Spray an appropriate amount of water on 1 ton of sunflower plate composite material powder, stir it evenly with a mixer, and leave it overnight. After one day of absorption and evaporation, the water content of the sunflower plate composite material powder is about 50%;

[0053] (2) Activation and cultivation of strains: Pseudomonas aeruginosa, Streptomyces albicans, Bacillus licheniformis, Flavobacterium, Bacillus jelly-like and Bacillus megaterium were respectively activated and cultured on the inclined surface of the test tube, and activated on the inclined surface of the test tube. The strains were transferred to shake flasks for cultivation.

[0054] Activation and cultivation of the Pseudomon...

Embodiment 3

[0064] Embodiment three: strain fermentation test

[0065] The uninoculated sunflower disc composite material was used as a control to observe the appearance of the culture, determine the content of crude protein, and determine the content of cellulose.

[0066](1) Fermentation test of a single strain: Weigh the sunflower dish composite material in the fermentation tank, spray an appropriate amount of water, and stir it evenly with a mixer, and leave it overnight. After one day of absorption and evaporation, the water content of the sunflower dish powder composite material is 40%-60%; single-bacteria fermentation was inoculated with Pseudomonas aeruginosa, Streptomyces albicans, Bacillus licheniformis, Flavobacterium, Bacillus jelly-like and Bacillus megaterium at an inoculation ratio of 1.5%; cultured at 30°C for 48 hours , the thickness of the material in the fermenter is 40cm, observe the appearance of the culture, measure the crude protein content and the cellulose conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com