A Solid-liquid Separation Process Combined with Multi-effect Evaporation and Stirred Evaporation

A technology of solid-liquid separation and multi-effect evaporation, which is applied in the direction of multi-effect evaporation, evaporation, separation methods, etc., can solve the problems of multi-effect evaporation treatment efficiency reduction, liquid equilibrium partial pressure reduction, and complicated processing process, so as to achieve energy efficiency. The effects of integration and comprehensive utilization, reduction of energy consumption for solid-liquid separation, and improvement of transportation convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

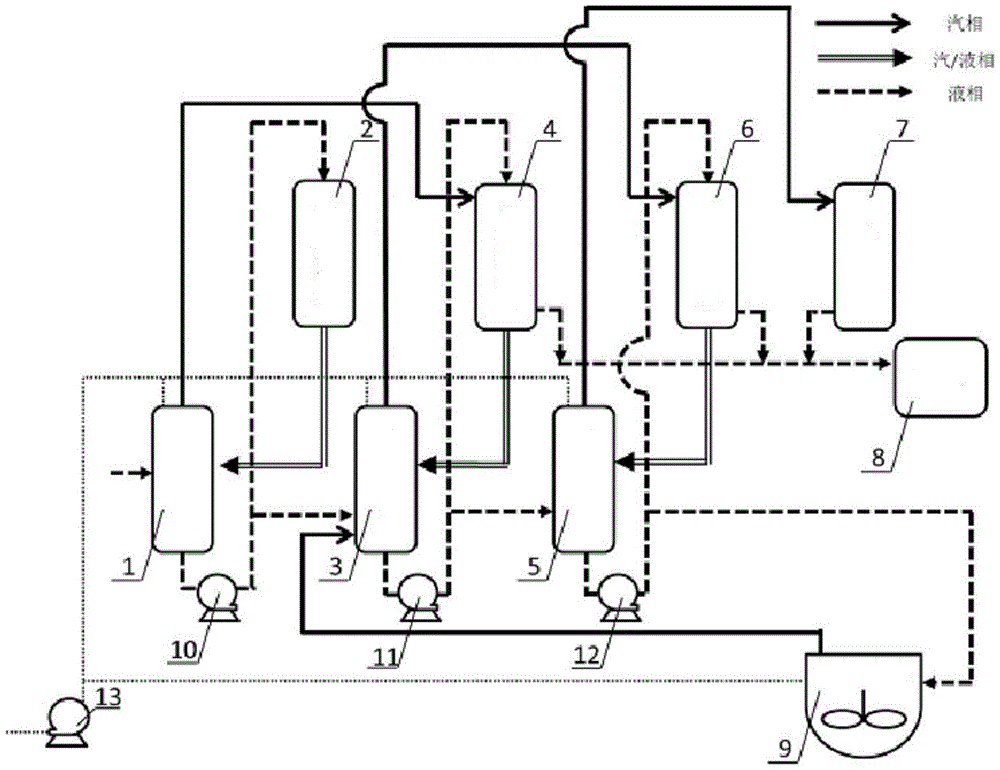

Image

Examples

Embodiment 1

[0045] The acetic acid-water solution system contains potassium chloride, phosphoric acid and its metal and ammonium salts, organic phosphoric acid and its metal and ammonium salts, and acetamide, with a total mass content of about 4.5%.

[0046] The pretreated acetic acid-water solution is transported to the three-effect evaporator through the feed pump for evaporation treatment. In the first-effect evaporator, steam is used as the external heat source, and the acetic acid-water solution system is heated in a downstream manner. When the three-effect separator When the concentration of dissolved solids in the mixed solution reaches 35% (at this time, it can be ensured that the total treatment capacity of multi-effect evaporation will be reduced by less than 20% due to the increase of solid concentration, and the multi-effect evaporation equipment will not be scaled and blocked, and the energy consumed by stirring and evaporation will be guaranteed. less than 5% of the total eva...

Embodiment 2

[0048] The formic acid-water solution system contains sodium chloride, diammonium hydrogen phosphate, and ammonium acetate, and its total mass content reaches 0.5%.

[0049] The pretreated formic acid-water solution is transported to the four-effect evaporator through the feed pump for evaporation treatment. In the first-effect evaporator, hot water is used as the external heat source, and the formic acid-water solution system is heated in a countercurrent manner. When the four-effect separator When the concentration of dissolved solids in the mixed solution reaches 25% (at this time, it can be ensured that the total treatment capacity of multi-effect evaporation will be reduced by less than 20% due to the increase of solid concentration, and the multi-effect evaporation equipment will not be scaled and blocked, and the energy consumed by stirring and evaporation will be guaranteed. less than 5% of the total evaporation energy), discharge the mixed solution into the stirred eva...

Embodiment 3

[0051] The ethanol-water solution system contains potassium sulfate, ammonium dihydrogen phosphate, and ammonium acetate, and its total mass content reaches 0.1%. The pretreated ethanol-water solution is transported to the five-effect evaporator through the feed pump for evaporation treatment. In the first-effect evaporator, the heat transfer oil is used as the external heat source, and the ethanol-water solution system is heated in a cross-flow manner. When the five-effect evaporator When the concentration of dissolved solids in the mixed solution in the effect separator reaches 30% (at this time, it can be ensured that the total treatment capacity of the multi-effect evaporation will be reduced by less than 20% due to the increase of the solid concentration, and the multi-effect evaporation equipment will not be scaled and blocked, and the stirring evaporation will be ensured. The energy consumed is less than 5% of the total evaporation energy), and the mixed solution is disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com