Surface modification method of polypropylene non-woven fabric

A polypropylene non-woven fabric and surface modification technology, which is applied in textiles, papermaking, fiber treatment, etc., can solve problems such as instability of self-assembled films, and achieve good application prospects, easy operation, and simple modification process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: the surface modification method of this polypropylene nonwoven fabric, specific content is as follows:

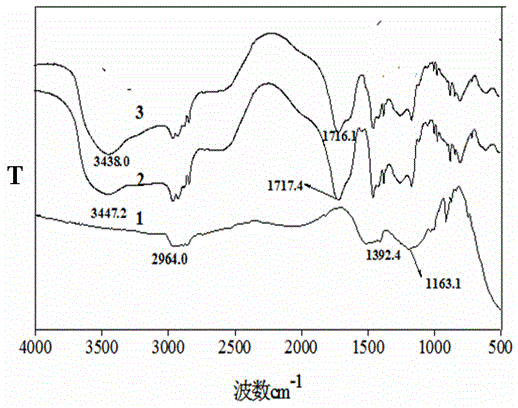

[0048] (1) Introduction of carboxyl groups on the surface of PP nonwoven fabric under UV irradiation

[0049] Refer to the method in the Chinese patent application (application number 201010559722.2) "A high carboxyl content ion-exchange non-woven fabric and its preparation method", the specific operation steps are as follows:

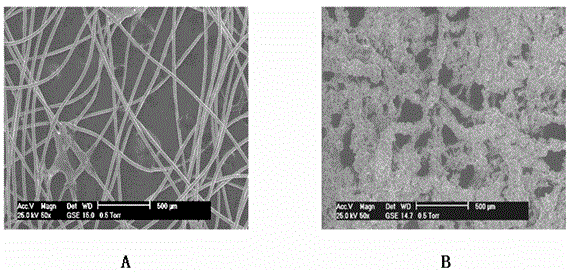

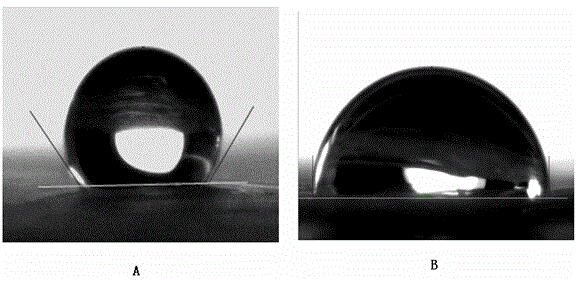

[0050] (A) Cut a batch of circular PP non-woven fabrics with a diameter of 8cm (area density 12.5g / m 2 , thickness 73.8μm, water absorption rate 52.1%), soak in acetone for 12h, remove surface oil and additives and other impurities, take it out and dry it for later use; (B) Mix acetone with 50% (volume percentage) and distilled water to make a mixed solvent , add acrylic acid, benzophenone and azobisisobutyronitrile to make a monomer solution for later use. 0.5g / L; (C) Soak the clean and dry PP non-woven fabric in the above mo...

Embodiment 2

[0063] Embodiment 2: the surface modification method of this polypropylene nonwoven fabric, specific content is as follows:

[0064] (1) Introduction of carboxyl groups on the surface of PP nonwoven fabric under UV irradiation

[0065] Carried out with reference to the method of Example 1, and the measurement results are shown in Table 2.

[0066] (2) Electrostatic self-assembly of carboxyl groups on the surface of PP non-woven fabrics and p-phenylenediamine monodiazonium salt cations

[0067]Weigh 3 parts of p-phenylenediamine and dissolve them in 2mol / L hydrochloric acid to prepare p-phenylenediamine solutions respectively. Dissolve sodium nitrite in distilled water to make a 1mol / L solution. Slowly add sodium nitrite solution in an equimolar amount to p-phenylenediamine in the diamine solution, and stir in the dark for 3 hours to obtain p-phenylenediamine monodiazonium salt cation solution, the concentration of which is 0.33 mmol / L.

[0068] Soak 3 parts of the PP non-w...

Embodiment 3

[0077] Embodiment 3: the surface modification method of this polypropylene nonwoven fabric, specific content is as follows:

[0078] (1) Introduction of sulfate groups on the surface of PP non-woven fabrics under UV irradiation

[0079] The mass concentration of preparing respectively is 15%, 20%, 25%, 30% and 35% ammonium persulfate aqueous solution;

[0080] Cut the PP non-woven fabric into a square and spread it on a piece of glass, then inject the ammonium persulfate solution into the PP non-woven fabric with a micro syringe to make it wet, and then put the polyethylene film (thickness 23 microns) on the PP non-woven fabric. Press it tightly on the cloth to form a sandwich structure, and then place it under a 500W ultraviolet lamp and irradiate it at a distance of 25 cm for 10 minutes; after the reaction, take out the PP non-woven fabric and soak it in 1mol / L hydrochloric acid for 0.5 hours, and then rinse it with distilled water three times , soaked in distilled water fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com