Europium-doped titanium dioxide/graphene oxide composite film and preparation method thereof

A graphene composite and titanium dioxide technology, applied in the direction of material excitation analysis, etc., can solve the problems of in-situ characterization of protein adsorption, achieve good adsorption, low cost, and simple PL test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

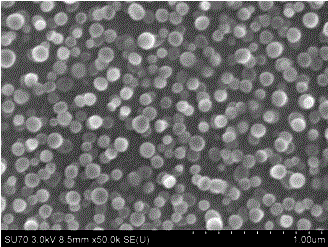

[0023] 1) Using the sol-gel method, the titanium dioxide precursor sol uses tetrabutyl titanate (TBOT) as the titanium source, ethanol as the solvent, and adds europium source Eu(TMHD) 3 , complexing agent acetylacetone (AcAc) and polyvinylpyrrolidone (PVP), the concentration of tetrabutyl titanate is 0.1 mol / L, Eu(TMHD) 3 The concentration was 0.01 mol / L, the molar ratio of acetylacetone, deionized water and tetrabutyl titanate was 0.3:1:1, stirred at room temperature to form a homogeneous sol; then, 20 μL of the precursor sol was taken at 8000 rpm Spin coating on the surface of the silicon wafer at a high speed, and the spin coating time was set at 40 s; after the spin-coated sample was kept at 500 °C for 2 h, a europium-doped titanium dioxide film without graphene oxide was obtained (see SEM image figure 1 ). The size of titanium dioxide nanodots is mostly 95-110 nm, and the density is about 5.4×10 10 / cm 2 .

Embodiment 2

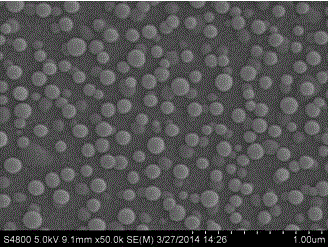

[0025] 1) First, graphene oxide and Eu(TMHD) 3 Add to absolute ethanol, stir until Eu(TMHD) 3 After completely dissolving, add tetrabutyl titanate (TBOT), complexing agent acetylacetone (AcAc) and deionized water, the molar ratio of acetylacetone, deionized water and tetrabutyl titanate is 0.3:1:1, Then add polyvinylpyrrolidone, stir well at room temperature, prepare tetrabutyl titanate concentration of 0.1 mol / L, polyvinylpyrrolidone concentration of 40 g / L, Eu(TMHD) 3 Concentration is 0.01 mol / L, and the concentration of graphene oxide is the titania precursor sol of 10 mg / L;

[0026] 2) Drop the titania precursor sol onto the cleaned silicon wafer surface until it is covered, spin-coat at 8000 rpm for 40 s, and then keep it at 500 °C for 2 h to obtain Eu-doped titania / oxide Graphene composite film. Its SEM image is shown in figure 2 , the size of titanium dioxide nanodots is mostly 90-105 nm, and the density is about 5.2×10 10 / cm 2 .

[0027] This example is compa...

Embodiment 3

[0029] 1) First, graphene oxide and Eu(TMHD) 3 Add to absolute ethanol, stir until Eu(TMHD) 3 After completely dissolving, add tetrabutyl titanate, complexing agent acetylacetone and deionized water, the molar ratio of acetylacetone, deionized water and tetrabutyl titanate is 0.3:1:1, then add polyvinylpyrrolidone, Stir well at room temperature, prepare tetrabutyl titanate concentration of 0.1 mol / L, polyvinylpyrrolidone concentration of 35 g / L, Eu(TMHD) 3 Concentration is 0.012 mol / L, and the concentration of graphene oxide is the titania precursor sol of 8 mg / L;

[0030] 2) The titania precursor sol was dropped onto the cleaned quartz glass surface until it was covered, and spin-coated at 8000 rpm for 40 s, and then kept at 500 °C for 2 h to obtain Eu-doped titania / Graphene oxide composite film, the size of titanium dioxide nano-dots is mostly 94-110 nm, and the density is about 5.1×10 10 / cm 2 .

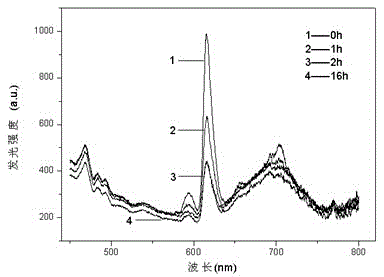

[0031] The PL test was performed on the sample prepared in this example,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com