A comprehensive treatment method for sulfur-containing alkali slag

A comprehensive treatment and alkali residue technology, applied in the direction of solid waste removal, etc., can solve the problems of no recovery of sulfur resources, adverse effects of activated sludge biological sewage treatment equipment, high COD concentration and salt content, and shorten the reaction time and equipment. Small size and COD reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

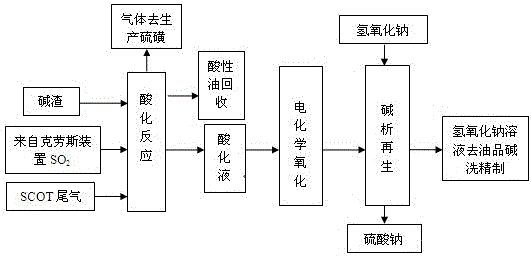

Image

Examples

Embodiment 1

[0043] A certain alkali washing liquid hydrocarbon alkali residue wastewater, in which COD is 3.21×10 5 mg / L, sulfide is 1.99×10 4 mg / L, volatile phenol 9.07×10 4 mg / L. Use the inventive method to process, introduce the SO contained in the Claus plant 2 Gas, that is, the raw material gas in the Claus unit, is introduced at the same time as the exhaust gas from the SCOT unit of the Claus unit’s tail gas treatment unit to acidify the alkali slag wastewater. By adjusting the ratio of the gas introduced, the volume content of hydrogen sulfide in the exhaust gas to 50%, the acidification is carried out until the pH of the alkali slag wastewater drops to 3, and the SO 2 Gas, continue to pass the exhaust gas of the SCOT device for 10 minutes.

[0044] After the acidification, the oil phase (mainly phenol) separated from the water layer was recovered by standing still. After the above acidification treatment, more than 99% of sulfides are removed, more than 80% of phenols are rem...

Embodiment 2

[0048] A certain liquid hydrocarbon and gasoline mixed alkali residue wastewater, in which COD is 2.35×10 5 mg / L, sulfide is 3.68×10 4 mg / L, volatile phenol 5.89×10 4 mg / L. Use the inventive method to process, introduce the SO contained in the Claus plant 2 Gas, that is, the raw material gas in the Claus unit, is introduced at the same time as the exhaust gas from the SCOT unit of the Claus unit’s tail gas treatment unit to acidify the alkali slag wastewater. By adjusting the ratio of the gas introduced, the volume content of hydrogen sulfide in the exhaust gas to 65%, the acidification is carried out until the pH of the alkali slag wastewater drops to 4, and the SO 2 Gas, continue to pass the exhaust gas of the SCOT device for 20 minutes.

[0049] After the acidification, the oil phase (mainly phenol) separated from the water layer was recovered by standing still. After the above acidification treatment, more than 99% of sulfides are removed, more than 80% of phenols are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com