Dendritic platinum-palladium alloy nanometer catalyst as well as preparation method and application thereof

A nano-catalyst, platinum-palladium alloy technology, applied in the direction of preparation of amino compounds, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the requirements of production equipment and process control The difficulty of hydrogenation and reduction of base compounds and the poor stability of battery packs have achieved high electrocatalytic stability, reduced energy consumption, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Dendritic Pt 15 Pd 85 (n(Pt(acac) 2 ) / n(Pd(acac) 2 )=1:1) Preparation of catalyst:

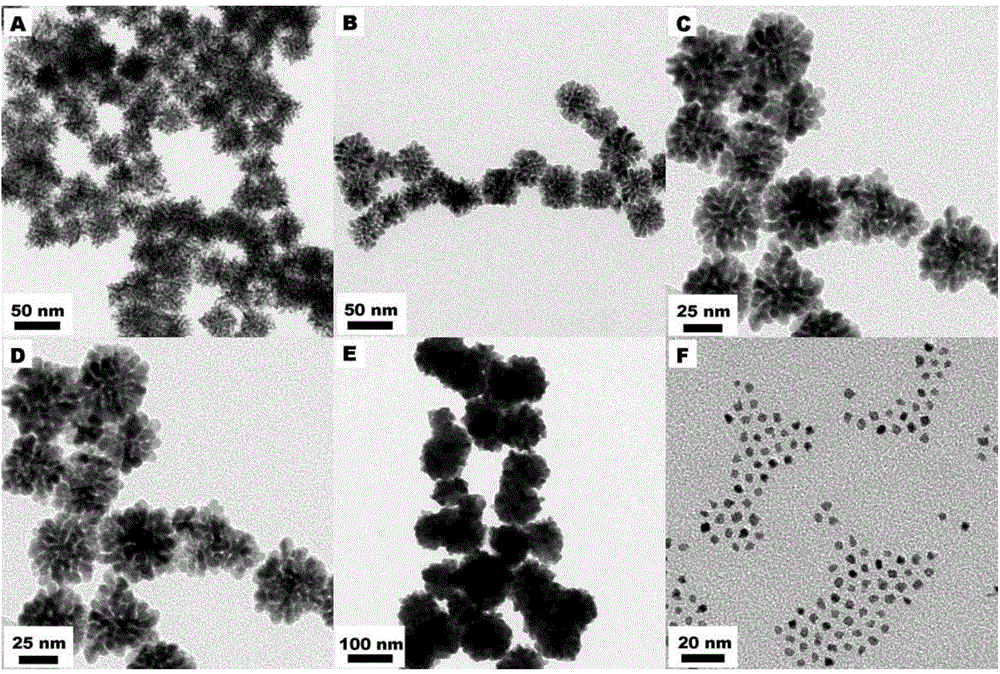

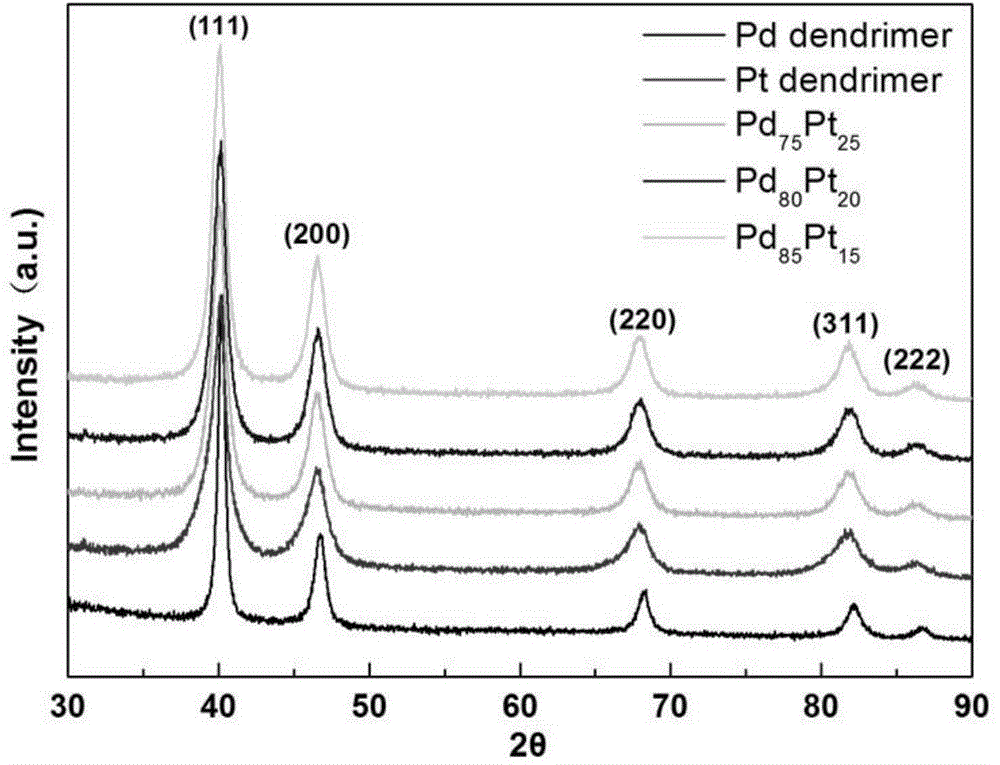

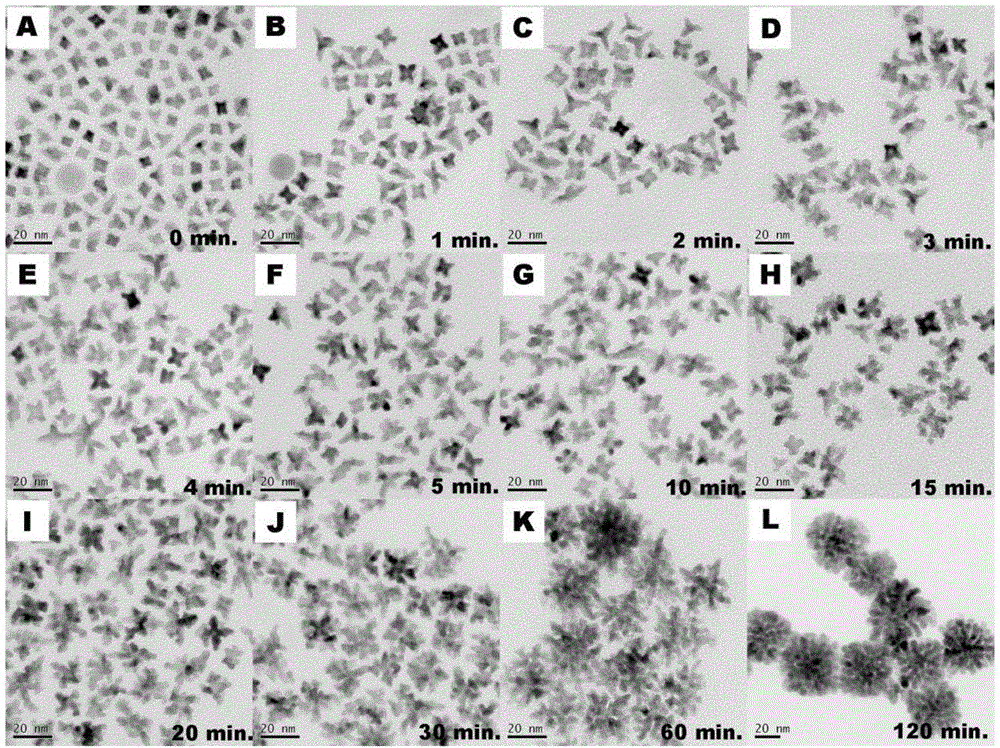

[0034] Mix 100 mg of platinum acetylacetonate, 77.45 mg of palladium acetylacetonate and 20 mL of oleylamine into a three-necked flask. Then put this mixed solution in a standard atmospheric pressure H 2 Slowly heat to 85°C in the atmosphere, the solution turns black, keep the temperature for 2 hours and then cool to room temperature, wash 2-3 times with absolute ethanol, and finally disperse the obtained solid in absolute ethanol for later use. See the TEM image figure 1 D in the XRD diagram, see figure 2 .

[0035] Figure 5 A, B are the cyclic voltammograms of Pt / Pd nanocatalysts and comparative platinum nanoparticles in a 0.5M sulfuric acid solution saturated with nitrogen; Figure 5 C and D are the current-voltage and current-time curves of methanol oxidation of Pt / Pd nanocatalysts and comparative platinum nanoparticles in a nitrogen-saturated 0.5M sulfuric acid and 0.5M methanol mi...

Embodiment 2

[0041] Dendritic Pt 20 Pd 80 (n(Pt(acac) 2 ) / n(Pd(acac) 2 )=1.5:1) Preparation of catalyst:

[0042] 100 mg of platinum acetylacetonate, 51.64 mg of palladium acetylacetonate, and 20 mL of oleylamine were mixed and uniformly added into the three-necked flask. Then put this mixed solution in a standard atmospheric pressure H 2 Slowly heat to 85°C in the atmosphere, the solution turns black, keep the temperature for 2 hours and then cool to room temperature, wash 2-3 times with absolute ethanol, and finally disperse the obtained solid in absolute ethanol for later use. See the TEM image figure 1 C, XRD diagram in figure 2 .

[0043] Figure 5 A, B are the cyclic voltammograms of Pt / Pd nanocatalysts and comparative platinum nanoparticles in a 0.5M sulfuric acid solution saturated with nitrogen; Figure 5 C and D are the current-voltage and current-time curves of methanol oxidation of Pt / Pd nanocatalysts and comparative platinum nanoparticles in a nitrogen-saturated 0.5M sulfuric a...

Embodiment 3

[0049] Dendritic Pt 25 Pd 75 (n(Pt(acac) 2 ) / n(Pd(acac) 2 )=2:1) Preparation of catalyst:

[0050] Mix 100 mg of platinum acetylacetonate, 38.73 mg of palladium acetylacetonate and 20 mL of oleylamine into a three-necked flask. Then put this mixed solution in a standard atmospheric pressure H 2 Slowly heat to 85°C in the atmosphere, the solution turns black, keep the temperature for 2 hours and then cool to room temperature, wash 2-3 times with absolute ethanol, and finally disperse the obtained solid in absolute ethanol for later use. See the TEM image figure 1 See B in XRD diagram figure 2 .

[0051] Figure 5 A, B are the cyclic voltammograms of Pt / Pd nanocatalysts and comparative platinum nanoparticles in a 0.5M sulfuric acid solution saturated with nitrogen; Figure 5 C and D are the current-voltage and current-time curves of methanol oxidation of Pt / Pd nanocatalysts and comparative platinum nanoparticles in a nitrogen-saturated 0.5M sulfuric acid and 0.5M methanol mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com