Nickel based corrosion-resisting alloy dendritic crystal etching agent and preparation method and using method thereof

A corrosion-resistant alloy and nickel-based technology, which is applied in the field of continuous casting metallographic analysis, can solve the problems of no patent reports on dendrite corrosion technology, and the inability to display the solidified dendrite structure of nickel-based corrosion-resistant alloys, and achieve simple inspection steps Convenient, clear and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

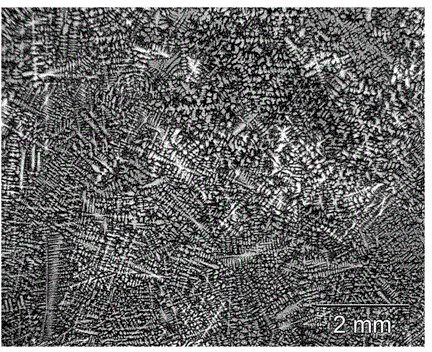

Embodiment 1

[0034] The dendrite corrosion reagent of the nickel-based corrosion-resistant alloy of the present embodiment is composed of stannous chloride, ferric chloride, hydrochloric acid, sodium alkylbenzene sulfonate, absolute ethanol and distilled water, and the specific composition ratio is:

[0035] Stannous Chloride SnCl 2 2H 2 O 6 grams;

[0036] Ferric Chloride FeCl 3 ·6H 2 O 50 grams;

[0037] Hydrochloric acid HCl 50 ml;

[0038] Absolute ethanol C 2 h 5 OH 60ml;

[0039] Sodium Alkylbenzene Sulfonate R-C 6 h 4 -SO 3 Na 20ml;

[0040] 270ml of distilled water.

[0041] Wherein the weight percent of hydrochloric acid concentration is 36%.

[0042]The preparation method of the dendritic corrosion reagent of the nickel-based corrosion-resistant alloy of the present embodiment is carried out according to the following steps:

[0043] First add 270ml of distilled water to the container, then add 50g of ferric chloride, 6g of stannous chloride and 50ml of hydrochloric...

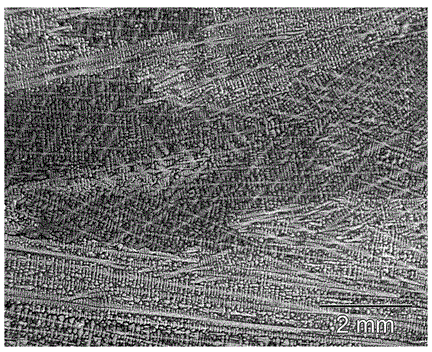

Embodiment 2

[0049] The dendritic corrosion reagent of the nickel-based corrosion-resistant alloy of the present invention is composed of stannous chloride, ferric chloride, hydrochloric acid, sodium alkylbenzene sulfonate, dehydrated alcohol and distilled water, and the specific composition ratio is:

[0050] Stannous Chloride SnCl 2 2H 2 O 18 grams;

[0051] Ferric Chloride FeCl 3 ·6H 2 O 65 grams;

[0052] Hydrochloric acid HCl 80 ml;

[0053] Absolute ethanol C 2 h 5 OH 35ml;

[0054] Sodium Alkylbenzene Sulfonate R-C 6 h 4 -SO 3 Na 15ml;

[0055] 40ml of distilled water.

[0056] Wherein the weight percentage of hydrochloric acid concentration is 38%.

[0057] The preparation method of the dendritic corrosion reagent of the nickel-based corrosion-resistant alloy of the present embodiment is carried out according to the following steps:

[0058] First add 40ml of distilled water to the container, then add 65g of ferric chloride, 18g of stannous chloride and 80ml of hydroc...

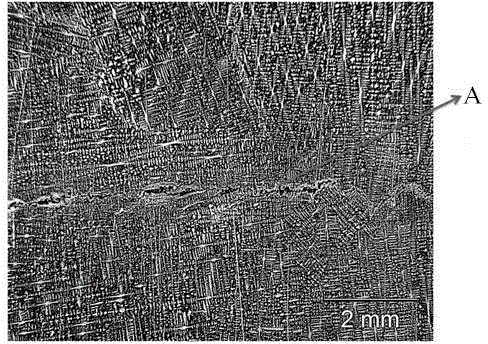

Embodiment 3

[0065] The dendrite corrosion reagent of the nickel-based corrosion-resistant alloy of the present embodiment is composed of stannous chloride, ferric chloride, hydrochloric acid, sodium alkylbenzene sulfonate, absolute ethanol and distilled water, and the specific composition ratio is:

[0066] Stannous Chloride SnCl 2 2H 2 O 12 grams;

[0067] Ferric Chloride FeCl 3 ·6H 2 O 70 grams;

[0068] Hydrochloric acid HCl 100 ml;

[0069] Absolute ethanol C 2 h 5 OH 10ml;

[0070] Sodium Alkylbenzene Sulfonate R-C 6 h 4 -SO 3 Na 30ml;

[0071] 300ml of distilled water.

[0072] Wherein the weight percent of hydrochloric acid concentration is 37%.

[0073] The preparation method of the dendritic corrosion reagent of the nickel-based corrosion-resistant alloy of the present embodiment is carried out according to the following steps:

[0074] First add 300ml of distilled water to the container, then add 70g of ferric chloride, 12g of stannous chloride and 100ml of hydroch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com