Transparent organic light-emitting device and method for manufacturing same

A luminescence and electromechanical technology, applied in the direction of electrical solid devices, semiconductor/solid device manufacturing, electrical components, etc., can solve the problems of low light transmittance, easy cracks, thick transparent devices, etc., and achieve good compactness and uniformity , low deposition temperature and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

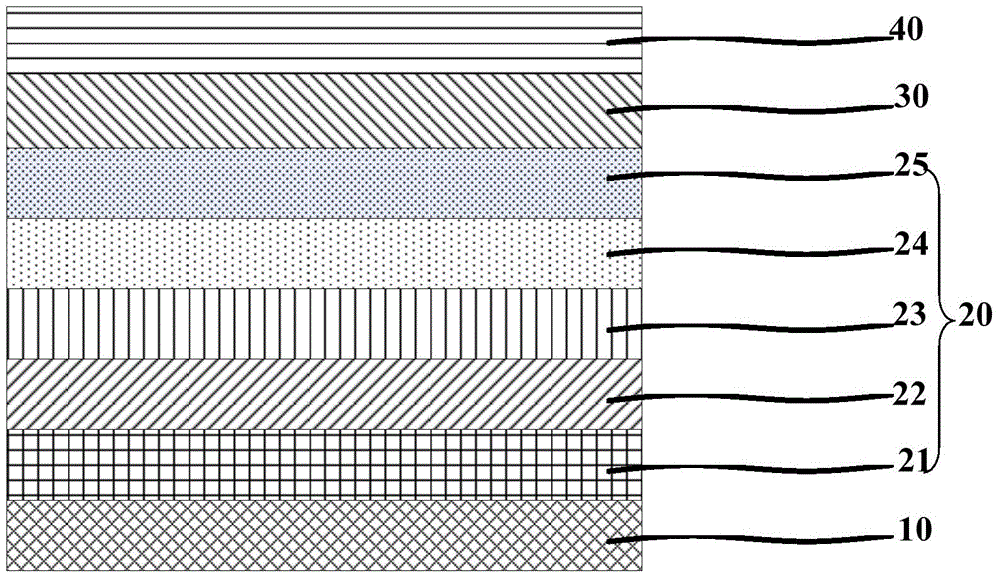

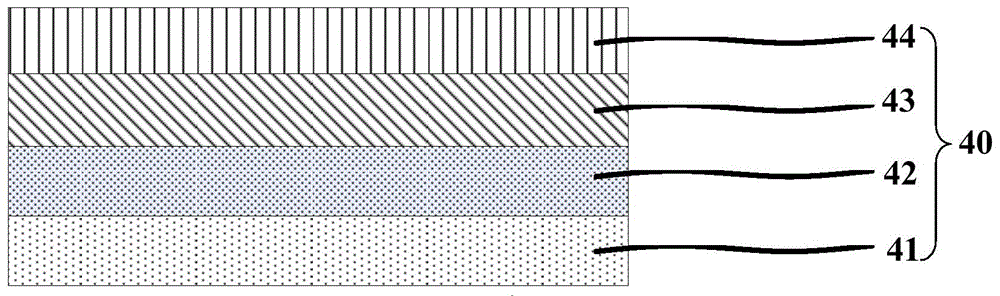

[0057] figure 1 It is the schematic diagram of the transparent organic electroluminescent device in embodiment 1; figure 1 As shown, the transparent organic electroluminescence device in Example 1 includes an ITO glass substrate (10), an organic light-emitting functional layer (20), a transparent cathode (30) and an encapsulation layer (40) stacked in sequence from bottom to top; The electroluminescent functional layer (20) includes a hole injection layer (21), a hole transport layer (22), a light emitting layer (23), an electron transport layer (24) and an electron injection layer (25) stacked in sequence from bottom to top . figure 2 yes figure 1 Schematic diagram of the structure of the encapsulation layer; such as figure 2 As shown, the encapsulation layer (40) includes a mixed barrier layer (41), a first silicon oxynitride film layer (42), an inorganic barrier layer (43) and a second oxygen Silicon nitride film layer (44).

[0058] A method for preparing a transpar...

Embodiment 2

[0076] A method for preparing a transparent organic electroluminescent device, comprising the steps of:

[0077] (1), (2), (3) are the same as embodiment 1;

[0078] (4) Preparation of encapsulation layer:

[0079] a) Preparation of mixed barrier layer: The mixed barrier layer was prepared on the surface of the transparent cathode by vacuum evaporation method, and the vacuum degree was 5×10 -5 Pa, the evaporation rate is The mixed barrier layer materials include N,N'-diphenyl-N,N'-di(1-naphthyl)-1,1'-biphenyl-4,4'-diamine (NPB) and doped in Rhenium oxide (ReO) in N,N'-diphenyl-N,N'-bis(1-naphthyl)-1,1'-biphenyl-4,4'-diamine (NPB), rhenium oxide The mole fraction of (ReO) is 50%; the thickness of the mixed barrier layer is 250nm;

[0080] b) Preparation of the first silicon oxynitride film layer: the first silicon oxynitride film layer was prepared on the surface of the mixed barrier layer by plasma enhanced chemical vapor deposition, the working pressure was 10Pa, the dep...

Embodiment 3

[0085] A method for preparing a transparent organic electroluminescent device, comprising the steps of:

[0086] (1), (2), (3) are the same as embodiment 1;

[0087] (4) Preparation of encapsulation layer:

[0088] a) Preparation of mixed barrier layer: The mixed barrier layer was prepared on the surface of the transparent cathode by vacuum evaporation method, and the vacuum degree was 5×10 -5 Pa, the evaporation rate is Hybrid barrier materials include 8-hydroxyquinoline aluminum (Alq 3 ) and doped in 8-hydroxyquinoline aluminum (Alq 3 ) in rhenium trioxide (Re 2 o 3 ), rhenium trioxide (Re 2 o 3 ) is 30% by mole fraction; the thickness of the mixed barrier layer is 200nm;

[0089] b) Preparation of the first silicon oxynitride film layer: the first silicon oxynitride film layer was prepared on the surface of the mixed barrier layer by plasma enhanced chemical vapor deposition, the working pressure was 50Pa, the deposition temperature was 60°C, and the radio frequenc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com