A semiconductor resistive gas sensor and its preparation method

A gas sensor, resistive technology, applied in the direction of material resistance, etc., can solve the problems of unfavorable device repetitive production and industrial production application, excessive initial resistance value of the device, cumbersome device preparation method, etc., achieve good market application prospects, reduce The difficulty of detection and the effect of realizing mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

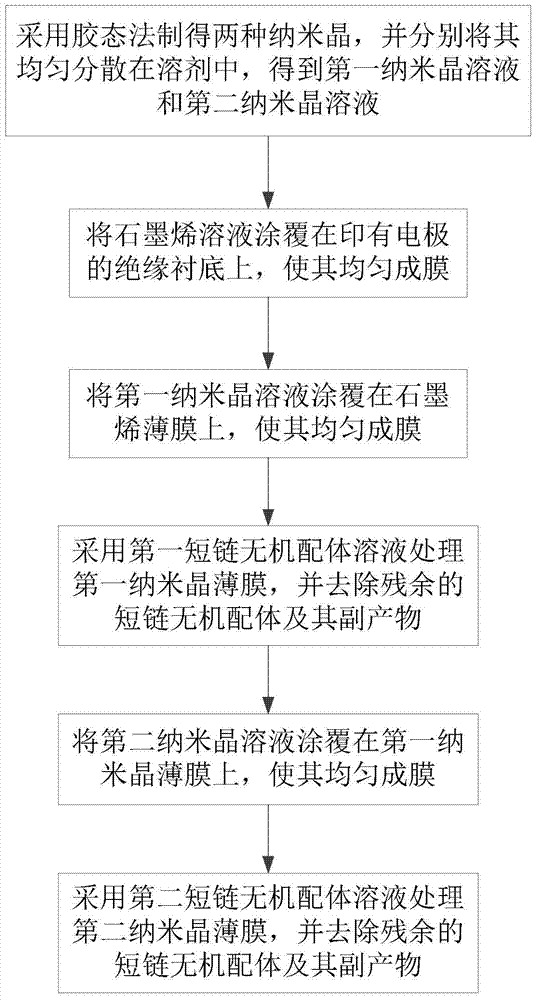

[0024] In the first embodiment of the present invention, the preparation method of the above-mentioned semiconductor resistive gas sensor comprises the following steps:

[0025] (1) Mix the precursor solutions of two kinds of nanocrystals, adopt a colloidal method to prepare a nanocrystal composite material, disperse it uniformly in a solvent, and mix graphene thereinto to obtain a composite solution;

[0026] (2) Coating the composite solution on an insulating substrate printed with electrodes to form a film uniformly;

[0027] Preferably, after the film is formed, the short-chain inorganic ligand solution is used to treat the film, and the remaining short-chain inorganic ligand and its by-products are removed;

[0028] (3) Repeat step (2) to obtain a gas-sensitive layer with a desired thickness, and complete the preparation of the gas sensor.

[0029] In the second embodiment of the present invention, the preparation method of the above-mentioned semiconductor resistive gas...

Embodiment 1

[0049] The preparation method of semiconductor resistive gas sensor comprises the steps:

[0050] (1) Preparation of SnO 2 Colloidal nanocrystal solution and CuO colloidal nanocrystal solution.

[0051] Among them, SnO 2 The preparation method of colloidal nanocrystal solution is specifically: under vacuum condition, 0.6g SnCl 4 ·5H 2 O, 20ml oleic acid (OA) and 2.5ml oleylamine (OLA) were mixed and stirred and heated to 80°C to prepare the precursor of tin oleate. After evacuating for 6 hours, the solution became clear. At this time, the heating and stirring were turned off, and nitrogen gas was passed into it to allow it to cool naturally. Inject 10ml of absolute ethanol into the above solution, take it out and transfer it to a stainless steel hydrothermal kettle and put it into an oven for hydrothermal reaction. Set the oven temperature to 180°C and keep it warm for 3 hours. After the hydrothermal reaction is over, take out the stainless steel hydrothermal kettle and p...

Embodiment 2

[0060] Steps (1) and (2) are the same as in Example 1, and steps (3) to (5) are specifically:

[0061] (3) The CuO colloidal nanocrystal solution is evenly dropped on the graphene film, spin-coated at a speed of 1300rpm for 30s, and repeated three times to make it evenly form a film;

[0062] Copper chloride (CuCl 2 ) with anhydrous methanol solution covering the entire nanocrystalline film, soaking for 45s and drying, repeating three times; soaking with anhydrous methanol for 15s and drying, repeating three times to remove residual CuCl 2 Particles and their reaction by-products.

[0063] (4) SnO 2 The colloidal nanocrystal solution is evenly dropped on the CuO colloidal nanocrystal film, spin-coated at a speed of 1300rpm for 30s, and repeated twice to form a uniform film;

[0064] Copper chloride (CuCl 2 ) with anhydrous methanol solution covering the entire nanocrystalline film, soaking for 45s and drying, repeating three times; soaking with anhydrous methanol for 15s a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com