Thick film pyroelectric sensitive element and preparation method thereof

A sensitive element and pyroelectric technology, which is applied in the manufacture/processing of thermoelectric devices, the lead-out material of thermoelectric device junctions, and electrical radiation detectors. The problem of high production cost is to achieve the effect of being sensitive to weak environmental temperature changes, conducive to industrial production, and easy to batch process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

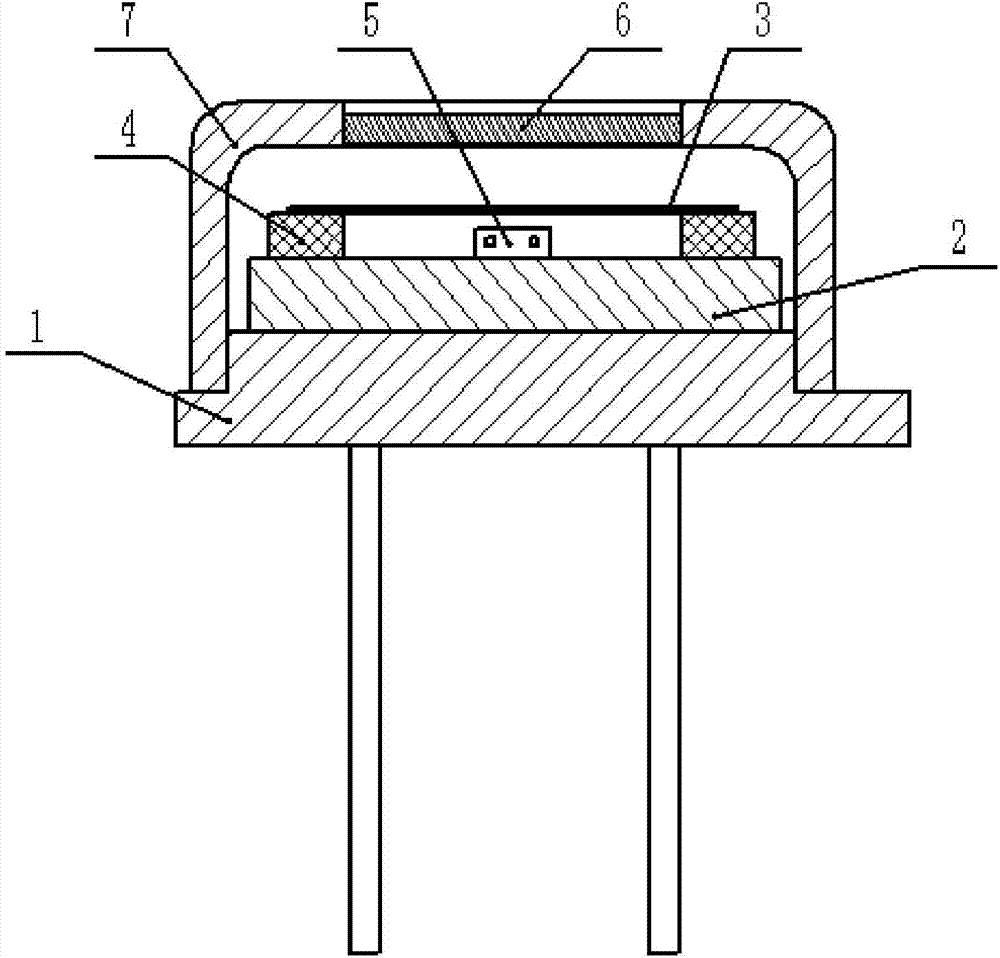

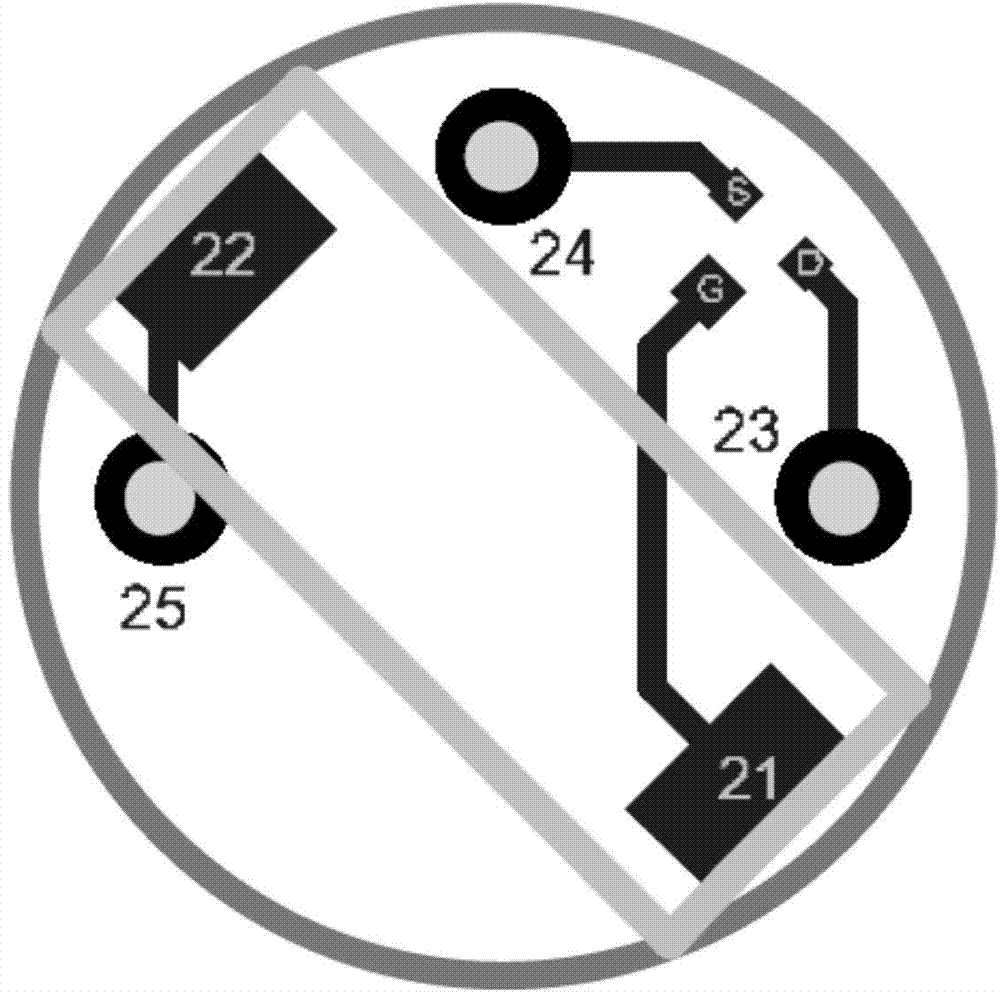

[0031] The technical solutions, structural features and realization effects of the present invention will be further described in detail below through specific implementation methods and accompanying drawings.

[0032] The preparation process steps of the pyroelectric infrared sensitive element 3 of the present invention include:

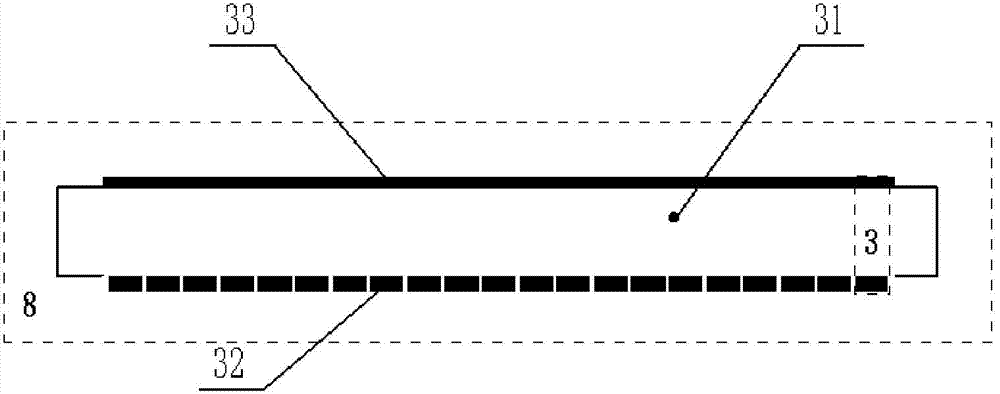

[0033] 1. Preparation of the heat-sensitive layer 31 .

[0034] 1) Mix BST and PVDF into N,N-dimethylformamide (DMF) at a mass ratio of 1:1, wherein, PVDF:DMF=1:7, and ultrasonically stir until a uniformly mixed slurry is obtained;

[0035] 2) Spray the slurry prepared in step 1) on a flat glass substrate by spraying method, and then let it stand for 10 minutes. After the slurry is leveled, put it into an oven at 80°C. After drying to form a thick film, remove it from the glass substrate peeled off and fixed in a plane fixture, the two surfaces of the fixture are made of glass or metal foil with good flatness and thermal stability, and then kept in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com