A kind of polyurethane exterior wall anticorrosion flame retardant coating and preparation method thereof

A flame retardant coating, polyurethane technology, applied in the direction of polyurea/polyurethane coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve the problems such as not very mature, achieve the effect of improving the strength of the paint film, shortening the baking time, and increasing the hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

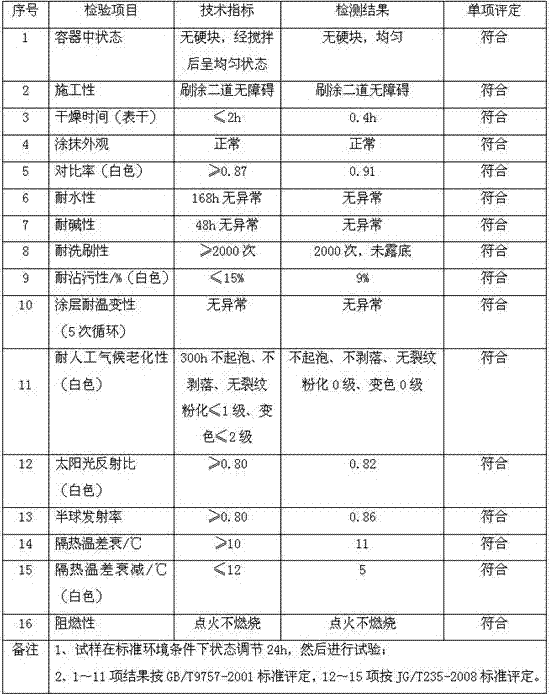

Image

Examples

Embodiment 1

[0045] First, according to weight parts, 45 parts of polyurethane prepolymer, 2 parts of N-methylol acrylamide, 3 parts of dioctyl terephthalate, 0.5 parts of titanate coupling agent TMC-101, dispersant ammonium polyacrylate Salt DA40 0.3 parts, rutile titanium dioxide 15 parts, antifoaming agent polyoxypropylene glyceryl ether 0.2 parts, silica lime powder 6 parts, mixed solvent (lignin + propylene glycol methyl ether + water, the weight ratio is 2:1:9) 12 parts, flame retardant material (prepared by weight ratio of pentaerythritol and xylenyl phosphate 1:1) 5 parts, preservative (2-methyl-4-isothiazolin-3-one) 3 parts, coloring pigment molybdenum chrome red One part and 2 parts of leveling agent acrylate are prepared.

[0046] The production method is to add 1.8 kg of ethanol with a volume concentration of 70-85% per kg of N-methylol acrylamide by weight to dissolve it, and then mix it with the polyurethane prepolymer in the reactor. The reaction temperature is 80°C and the rea...

Embodiment 2

[0048] First, according to the weight parts, 50 parts of polyurethane prepolymer, 3 parts of N-methylol acrylamide, 4 parts of dioctyl terephthalate, 0.7 parts of titanate coupling agent TMC-101, dispersant ammonium polyacrylate Salt DA40 0.5 parts, rutile titanium dioxide 17 parts, antifoaming agent polyoxypropylene glyceryl ether 0.3 parts, silica lime powder 8 parts, mixed solvent (lignin + propylene glycol methyl ether + water, the weight ratio is 2:1:9) 14 parts, flame-retardant materials (prepared by weight ratio of pentaerythritol and melamine 1:1) 8 parts, preservative (5-chloro-2-methyl-4-isothiazolin-3-one) 5 parts, coloring Prepare 2 parts of pigment toluidine red and 3 parts of antifreeze benzyl alcohol.

[0049] The production method is to add 1.8 kg of ethanol with a volume concentration of 70-85% per kg of N-methylol acrylamide by weight, and then mix it with the polyurethane prepolymer in the reactor. The reaction temperature is 120°C, and the reaction time is 1.5...

Embodiment 3

[0051] First, according to the weight parts, 55 parts of polyurethane prepolymer, 4 parts of N-methylol acrylamide, 5 parts of dioctyl terephthalate, 1.0 part of titanate coupling agent TMC-101, dispersant ammonium polyacrylate Salt DA 400.6 parts, rutile titanium dioxide 20 parts, antifoaming agent polyoxypropylene glycerol ether 0.5 parts, silica lime powder 10 parts, mixed solvent (lignin + propylene glycol methyl ether + water, the weight ratio is 2:1:9 ) 15 parts, flame-retardant materials (prepared by weight ratio of dimethyl phosphate and melamine 1:1) 10 parts, preservative (5-chloro-2-methyl-4-isothiazolin-3-one) 7 parts, one part of coloring pigment phthalocyanine blue B, 5 parts of anti-settling agent organic bentonite, prepare materials.

[0052] The production method is to add 1.8 kg of ethanol with a volume concentration of 70-85% per kg of N-methylol acrylamide by weight to dissolve it, and then mix it with the polyurethane prepolymer in the reactor. The reaction t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com