Porous foam body heavy metal adsorption material preparation method

A technology of adsorption material and porous foam, which is applied in the preparation of heavy metal adsorption materials and the field of preparation of porous foam heavy metal adsorption materials, which can solve the problems of difficult separation and achieve the effects of convenient use, cost reduction, and recyclable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

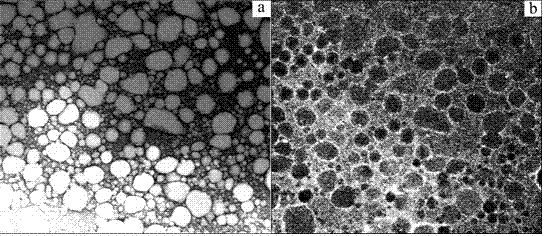

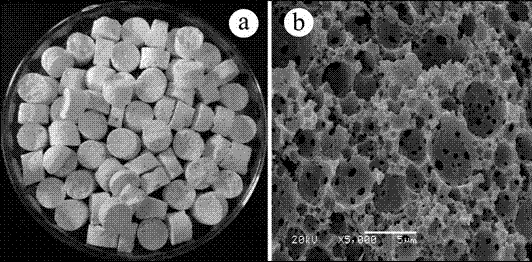

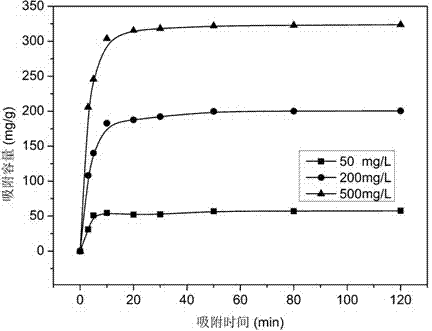

Embodiment 1

[0042] 0.5g chitosan, 2.0g acrylamide, 2.0g acrylic acid, 1.25g N,N' -Methylenebisacrylamide, 3.5g of fatty alcohol polyoxyethylene ether surfactant, 0.5g of initiator potassium persulfate are dispersed in 10 mL of water; after each component is dissolved, add 60 mL of liquid paraffin to the mixed solution and stir 4h; the obtained high-concentration emulsion was put into a columnar tube, sealed, and polymerized at 50°C for 12h. The obtained polymer was extracted by Soxhlet with n-hexane for 48 hours, dehydrated with industrial ethanol, and dried in vacuum to obtain a porous adsorption material. The adsorption material for heavy metal Cu 2+ and Pb 2+ The desorption amounts of 325 mg / g and 586 mg / g were respectively.

Embodiment 2

[0044] Mix 1.0g chitosan, 2.0g 2-acrylamide-2-methyl-propanesulfonic acid, 1.0g methyl methacrylate, 0.5 g ethylene glycol dimethacrylate, 2.0 g sorbitol under stirring at 300rpm Fatty acid ester surfactants, 2.0g polyoxyethylene and polyoxypropylene block copolymer surfactants, and 0.2g initiator ammonium persulfate were dispersed in 20 mL of water; after each component was dissolved, drop Add 60 mL of n-octane and stir for 1 h; the obtained high-concentration emulsion is put into a columnar tube, sealed, and polymerized at 40°C for 24 h. The obtained polymer was Soxhlet-extracted with n-hexane for 12 hours, dehydrated with industrial ethanol, and dried in vacuum to obtain a porous adsorption material. The adsorption material for heavy metal Cu 2+ and Pb 2+ The desorption amounts of 218 mg / g and 524 mg / g were respectively.

Embodiment 3

[0046] Mix 1.0 g chitosan, 2.0 g methacrylic acid, 0.5 g hydroxypropyl methacrylate, 2.5 g trimethylolpropane trimethacrylate, 5.0 g alkylphenol polyethylene oxide ether under stirring at 600 rpm Disperse 0.75 g ammonium persulfate-like surfactant and initiator in 15 mL water; after each component is dissolved, add 55 mL of toluene dropwise to the mixed liquid and stir for 1 h; Polymerization 12h. The obtained polymer was extracted by Soxhlet with n-hexane for 24 hours, dehydrated with industrial ethanol, and dried in vacuum to obtain a porous adsorption material. The adsorption material for heavy metal Cu 2+ and Pb 2+ The desorption amounts of 332 mg / g and 605 mg / g respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com