A protein hydrophobic separation and purification membrane based on cellulose fibers

A cellulose fiber, separation and purification technology, applied in the direction of semi-permeable membrane separation, membrane technology, hydrolase, etc., can solve the problems of loss of cellulose fiber, complex membrane production process, large fluid flux, etc., and achieve short graft chains. , the preparation method is simple, the performance is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] According to the present invention, a protein hydrophobic separation and purification membrane is provided, and the preparation method of the membrane comprises the following steps:

[0025] ①Mercerizing treatment: disperse the cellulose fiber in the ethanol solution of alkali, stir and soak at room temperature for 12h~24h;

[0026] Wherein, the fiber is cellulose fiber through beating treatment, including one or more mixed fibers in wood fiber, herbaceous fiber and cotton fiber, preferably wood fiber and cotton fiber;

[0027] Wherein, the alkali includes one or more of sodium hydroxide, potassium hydroxide, sodium ethylate, preferably sodium hydroxide or potassium hydroxide;

[0028] ②Drying: remove the liquid phase material by filtration, remove ethanol from the fiber under reduced pressure at 60°C~80°C;

[0029] ③Grafting modification: place the dry fiber in a reactor and heat and dry it at 95°C~120°C for 2h~4h, then mix it with hydrophobic epoxy monomer in an iner...

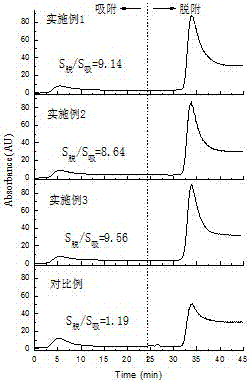

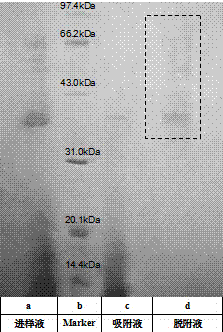

Embodiment 1

[0049] Mercerizing treatment: Disperse 100g of wood fiber in a mixed solution composed of 10g of potassium hydroxide, 72g of absolute ethanol and 18g of water, stir and soak at room temperature for 24h;

[0050] Drying: After filtering, dry the fiber under reduced pressure at 70°C to remove ethanol;

[0051] Graft modification: under the protection of nitrogen, mix 50g of mercerized fibers with 10g of dry styrene oxide monomer, and react at 80°C for 24h;

[0052] Refining: carry out Soxhlet extraction and reflux for 10 h with tetrahydrofuran as solvent to remove impurities, then wash / filter with water until the pH of the filtrate is neutral. After freeze-drying, polystyrene-modified wood fibers were obtained, and the grafting rate was 12%.

[0053] Membrane production: Weigh 0.2g of polystyrene oxide modified wood fiber in the aqueous solution, stir until it is evenly dispersed, pour it into a filter cartridge with an inner diameter of 2cm, filter and press to obtain a fiber ...

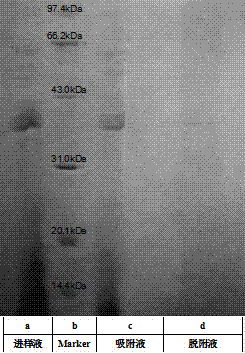

Embodiment 2

[0055] Mercerizing treatment: Disperse 100g wood fiber in a mixed solution composed of 15g potassium hydroxide, 108g absolute ethanol and 27g water, stir and soak at room temperature for 24h;

[0056] Drying: After filtering, dry the fiber under reduced pressure at 80°C to remove ethanol;

[0057] Graft modification: under nitrogen protection, mix 50g of mercerized fiber with 7.5g of dry styrene oxide monomer, and react at 90°C for 24h;

[0058] Refining: carry out Soxhlet extraction and reflux for 18 hours with tetrahydrofuran as solvent to remove impurities, then wash / filter with water until the pH of the filtrate is neutral. After freeze-drying, polystyrene-modified wood fibers were obtained, and the grafting rate was 9%.

[0059] Membrane production: Weigh 0.2g of polystyrene oxide modified wood fiber in the aqueous solution, stir until it is evenly dispersed, pour it into a filter cartridge with an inner diameter of 2cm, filter and press to obtain a fiber filter cake, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com