Low burning temperature pyrotechnic gas generating agent composition

A technology of gas generating agent and composition, which is applied in the production of compressed gas, attacking equipment, etc., can solve the problems of reducing the burning temperature of the outlet gas, disadvantage, etc., and achieve the effect of increasing the burning rate, reducing the generation of dust and excellent thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~13、 comparative example 1

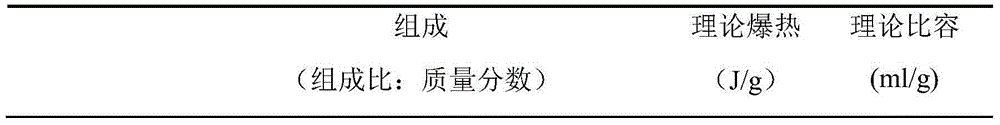

[0031] A gas generant composition having the composition shown in Table 1 was formulated. According to the theoretical calculation of these compositions, the theoretical heat of detonation (H O is liquid), specific volume (the unit ml / g represents the gas content produced per 1g of the composition, excluding water), the results are shown in Table 1.

[0032] Table 1

[0033]

[0034]

[0035] In Table 1, GN is guanidine nitrate, BCN is basic copper nitrate, DHG is dihydroxyglyoxime, and GZT is diguanidine azotetrazole. The other tables are also shown in the same manner. The average particle diameter of aluminum hydroxide in Table 1 is 2.16 μm (the same applies to other tables), the average particle diameter of sodium bicarbonate is 5.12 μm (the same applies to other tables), and the average particle diameter of dihydroxyglyoxime is 4.16 μm. μm (the same applies to other tables), and the average particle diameter of azotetrazole biguanide is 12.51 μm (the same applies t...

Embodiment 14~18

[0038] Gas generant compositions having the compositions shown in Table 2 were produced. These compositions test the detonation heat value of the gas generating agent according to GJB5891.29-2006, and test the gas specific volume value of the gas generating agent according to GJB5891.30-2006. test the result.

[0039] Table 2

[0040]

[0041]

[0042] Note: Fluorine rubber is added

[0043] In Examples 14-18, the measured detonation heat value is lower than that of Comparative Example 2, which is consistent with the theoretically calculated value. All four cooling agents can reduce the detonation heat of the gas generating agent, and the addition of DHG can increase the specific volume of the gas generating agent.

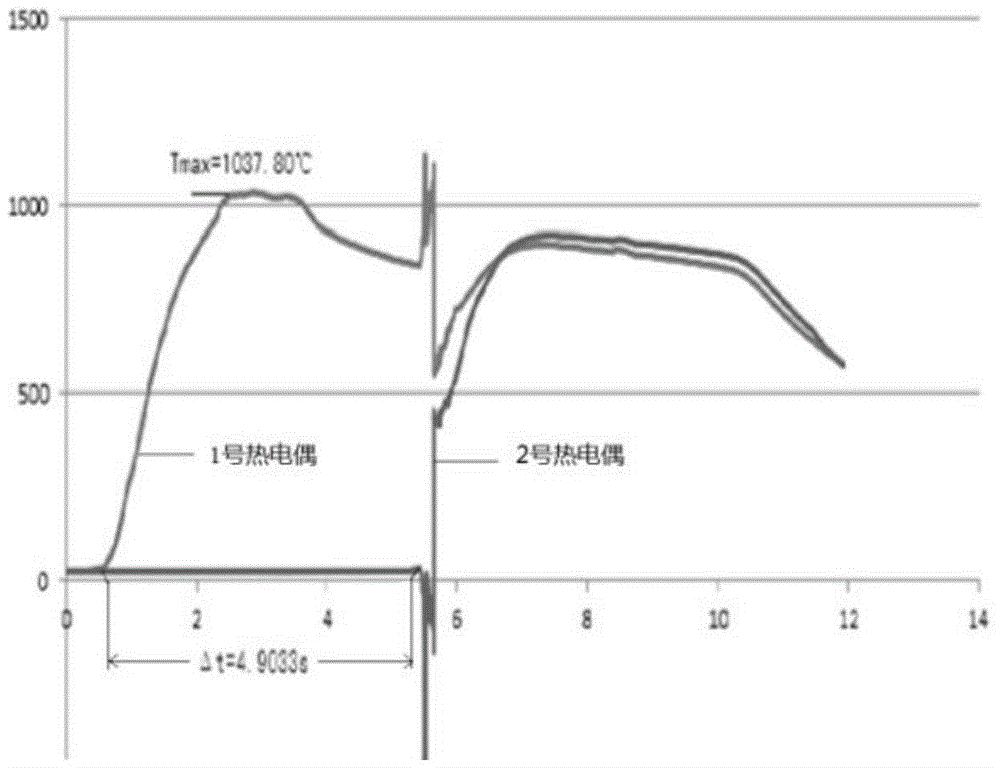

Embodiment 19~27

[0045] Pyrotechnic gas generant compositions having the compositions shown in Table 3 were produced. These compositions are molded into a cylinder with a diameter of Φ8mm, and the cylinder is put into a plexiglass tube of the same size. The wall thickness of the plexiglass tube is 3mm. Insert two 0.25mm thin K-type thermocouples into the two holes to the center of the powder column. The thermocouple near the ignition end is No. 1 thermocouple, and the thermocouple far away is No. 2 thermocouple. Open the system under normal pressure. , to measure the burning temperature and burning rate of the gas generating agent. The burning temperature is the higher one of the highest temperatures measured by the two thermocouples, the time difference between the highest temperatures of the two thermocouples is t, and the burning rate is determined as rb=h / t, each group of samples is measured three times, and the average is taken Value, a test result of comparative example 2 such as figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com