Microring electrode and production method thereof

A micro-electrode and micro-electrode array technology, which is applied in the fields of material electrochemical variables, liquid chemical plating, metal material coating process, etc., can solve the problems of difficult preparation, limited research and application, few preparation reports, etc. Low cost, controllable electrode size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

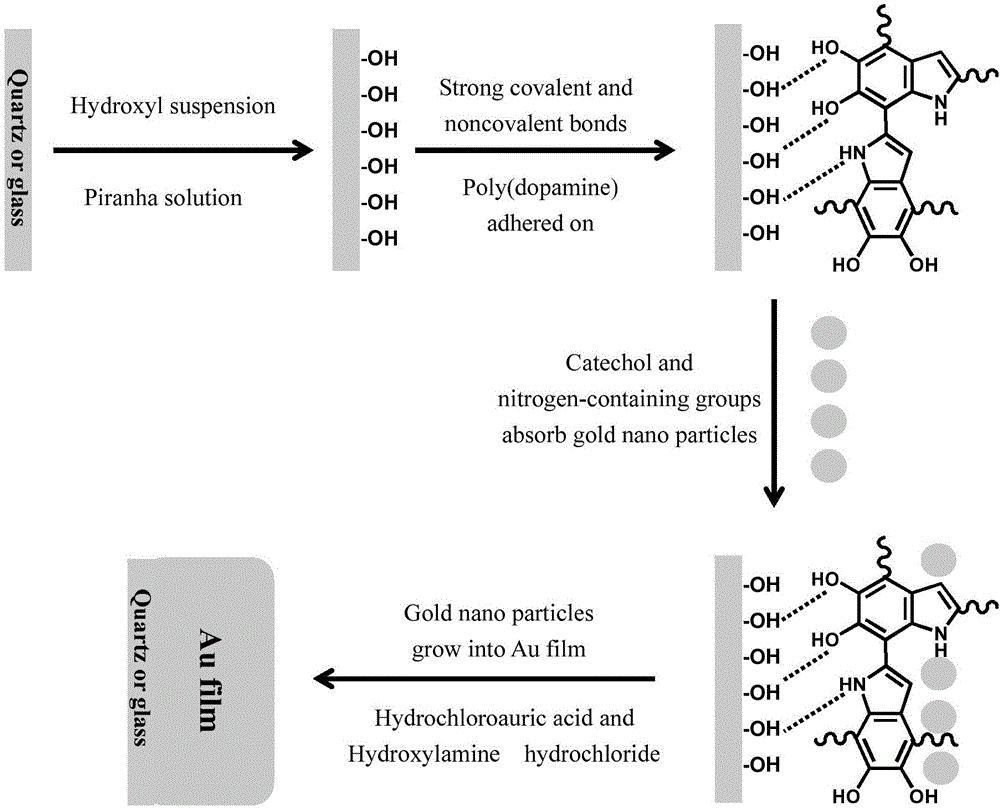

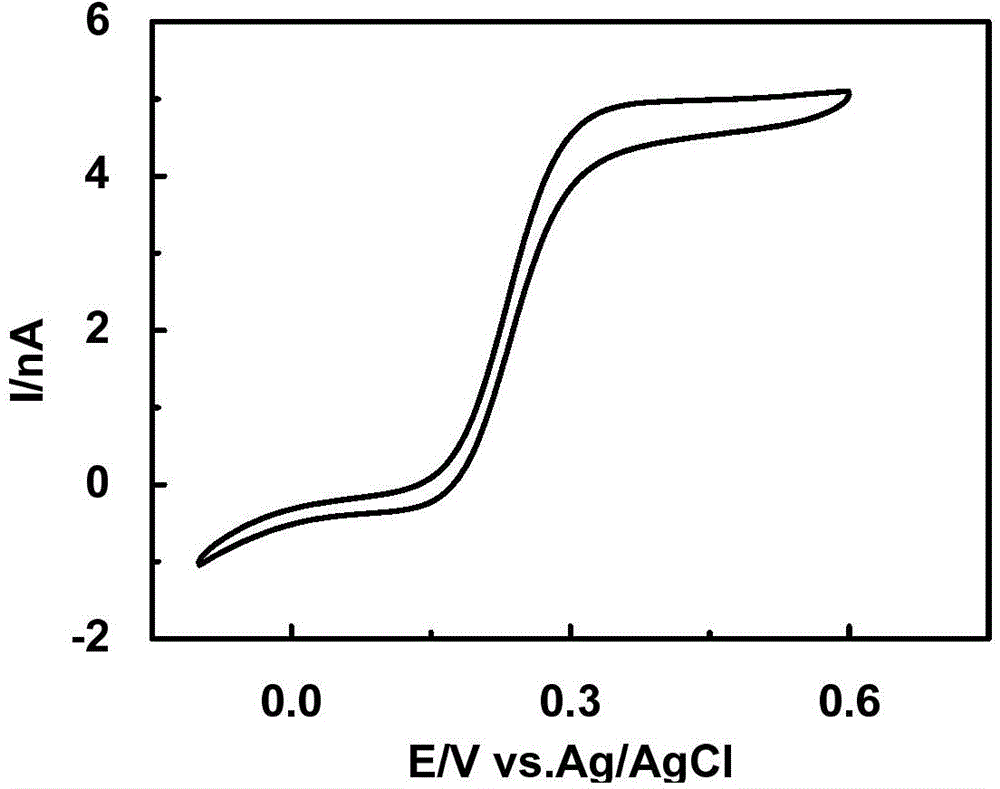

[0034] Embodiment 1, preparation gold film microelectrode

[0035] 1) Preparation of nano gold sol:

[0036] After heating 100mL of the aqueous solution of 0.1% mass percent concentration of chloroauric acid to boiling, add 2.5mL of the mass percent concentration of 1% sodium citrate aqueous solution, and reflux for 10min. Remove the heat source, and wait for the solution to cool to room temperature to obtain nano-gold sol, which should be stored at low temperature and protected from light.

[0037] 2) Preparation of support body:

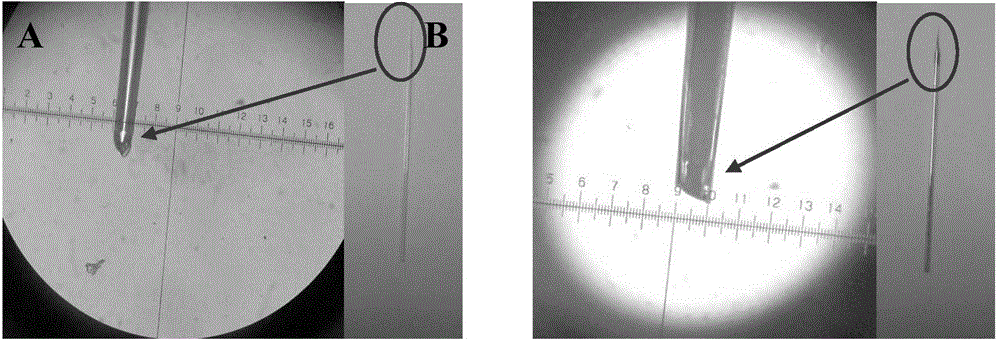

[0038] A quartz capillary was drawn into a micron-sized tip on a P-97 puller, and the diameter of the micron-sized tip was 5-50 μm, which was used as a support for preparing a gold film electrode in the next step.

[0039] 3) Wet deposition of gold on the inner wall of the capillary:

[0040]Push 2.0mL of acetone and 1.5mL of deionized water into the support drawn in 2) in turn under the push of a micro-syringe pump for cleaning, and the cleanin...

Embodiment 2

[0049] Embodiment 2, preparation gold film microelectrode

[0050] 1) Preparation of nano-gold sol: according to embodiment 1 step 1), only the aqueous solution of chloroauric acid with a mass percentage concentration of 0.1% is replaced with the aqueous solution of 0.05% chloroauric acid;

[0051] 2) Preparation of support body: same as step 2) of Example 1;

[0052] 3) Wet deposition of gold on the inner wall of the capillary:

[0053] Push 2.0mL of acetone and 2mL of deionized water into the support drawn in 2) in turn under the push of a micro-syringe pump for cleaning, and the cleaning flow rate is 10 μL / min;

[0054] Then the H with a volume ratio of 7:3 2 SO 4 / H 2 o 2 After the piranha solution formed was surface hydroxylated on the inner wall of the capillary for 10 minutes;

[0055] Under the push of a micro-injection pump, oxidize 3.0 mL of a dopamine aqueous solution with a mass concentration of 4 mg / mL in air for 15 min, push it into a capillary support whos...

Embodiment 3

[0060] Embodiment 3, preparation gold film microelectrode

[0061] 1) Preparation of nano-gold sol: according to embodiment 1 step 1), only the aqueous solution of the chloroauric acid of 0.1% is replaced by the aqueous solution of 0.2% by mass percent concentration, and 2.5mL mass percent concentration is 1% aqueous solution of sodium citrate was replaced by 2.0mL of 0.6% aqueous solution of sodium citrate;

[0062] 2) Preparation of support body: same as step 2) of Example 1;

[0063] 3) Wet deposition of gold on the inner wall of the capillary:

[0064] Push 2.0mL of acetone and 3.0mL of deionized water into the support drawn in 2) in turn under the push of a micro-syringe pump for cleaning, and the cleaning flow rate is 25 μL / min;

[0065] Then the H with a volume ratio of 7:3 2 SO 4 / H 2 o 2 After the piranha solution formed was surface hydroxylated on the inner wall of the capillary for 30 minutes;

[0066] Under the push of a micro-injection pump, 2.0 mL of dopam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com