Preparation of carbon nano fiber composite material coated by nitrogen-doped carbon nanotube and application thereof

A carbon nanofiber and nitrogen-doped carbon technology, which is applied in the analysis of materials, fiber chemical characteristics, and material analysis through electromagnetic means, can solve problems such as easy damage to three-dimensional structures, and achieve strong controllability, simple preparation methods, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

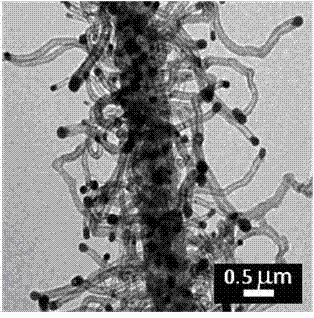

[0022] Dissolve 6 wt.% polyacrylonitrile and 10 wt.% iron acetylacetonate in dimethylformamide solution, and electrospin the above mixed solution for 0.5 h. The electric field strength of electrospinning is 60kV / m. The distance between the spinneret and the collecting plate was 30 cm, and the polyacrylonitrile composite fiber membrane containing metallic iron was obtained, and the obtained composite fiber membrane was annealed at 230°C for 3 h to obtain the oxidized composite fiber; the above-mentioned oxidized composite fiber was The temperature was raised to 850 °C at a rate of 5 °C / min and maintained for 1 h to obtain a carbon nanofiber composite material loaded with iron nanoparticles; the above carbon nanofiber composite material was used as a carbon substrate, and the flow rate of argon gas was adjusted to 150 sccm, and the Inject hydrogen, and adjust its flow rate to 50 sccm, use pyridine as the nitrogen source and carbon source, inject pyridine for 30 min, and after the...

Embodiment 2

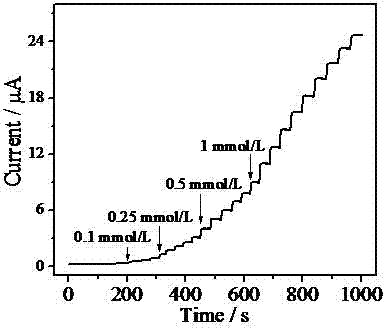

[0026] The nitrogen-doped carbon nanotube carbon nanofiber composite material prepared in Example 1 was cut into a circular film with a diameter of 3 mm and directly attached to the surface of the glassy carbon electrode (Φ=3 mm), and 4 mu L absolute ethanol on the surface of the composite film, and dried at room temperature to obtain a nitrogen-doped carbon nanotube carbon nanofiber composite modified glassy carbon electrode. Glucose oxidase was dissolved in 0.1M phosphate buffer solution (pH7.4) to make an 8 mg / mL enzyme solution, and 5 mu L was added dropwise on the modified glassy carbon electrode, and after drying, 5 mu L 0.5 wt.% Nafion solution was placed in a refrigerator at 4 °C to dry to obtain a glucose oxidase electrode. The enzyme electrode is used for the detection of glucose, and has a fast and sensitive response, and can reach a steady-state current within 5 s (see figure 2 ), the lowest detection limit is 0.2 mu

[0027] mol / L, the linear range is 0.5 mu...

Embodiment 3

[0029] Dissolve 6 wt.% polyacrylonitrile and 10 wt.% iron acetylacetonate in dimethylformamide solution, and electrospin the above mixed solution for 1 h. The electric field strength of electrospinning is 70kV / m. The distance between the spinneret and the collecting plate was 40 cm, and the polyacrylonitrile composite fiber membrane containing metallic iron was obtained, and the obtained composite fiber membrane was annealed at 230 °C for 3 h to obtain the oxidized composite fiber; the above oxidized composite fiber was heated in an argon atmosphere The temperature was increased to 800 °C at a rate of 5 °C / min and maintained for 1 h to obtain a carbon nanofiber composite material loaded with iron nanoparticles; the carbon nanofiber composite material obtained above was used as a carbon substrate, and the flow rate of argon gas was adjusted to 150 sccm , filled with hydrogen, and adjusted its flow rate to 50 sccm, using diethylamine as nitrogen source and carbon source, injected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com