A kind of preparation method of alcatadine intermediate

A catadine and intermediate technology, which is applied in the field of compound preparation, can solve the problems of unsuitable industrialization and enlargement, large environmental pollution, high equipment corrosiveness, etc., and achieves easy industrial production, easily available raw materials, and short synthesis routes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

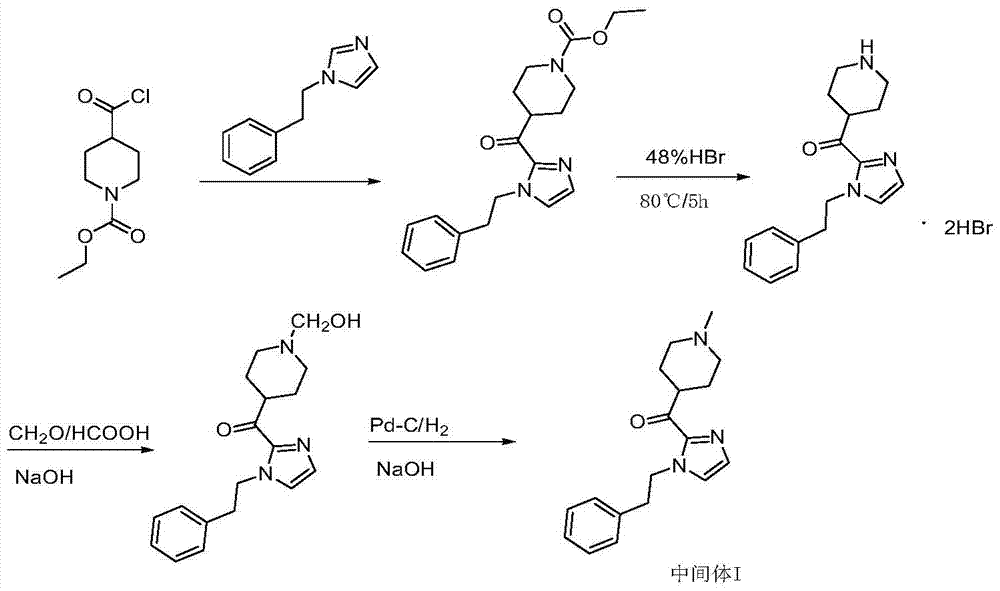

Problems solved by technology

Method used

Image

Examples

Embodiment 1

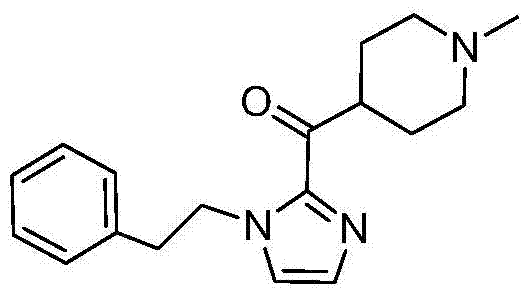

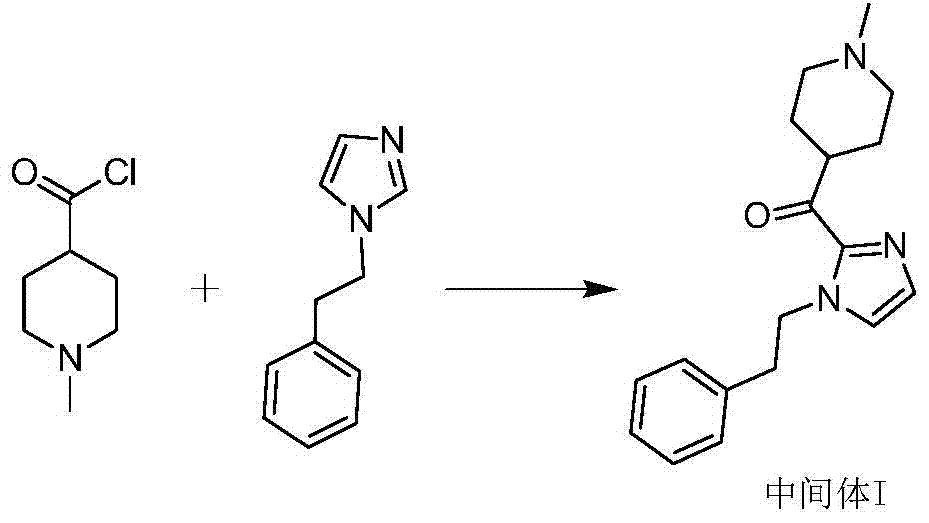

[0032] Preparation of [4-(1-methylpiperidine)][2-(1-phenethyl-1H-imidazole-)]methanone

[0033] Under the protection of nitrogen, dissolve 17.2g (0.1mol) of phenethylimidazole in 170mL of tetrahydrofuran, stir and cool down to below -40°C, add dropwise 50mL (0.125mol) of 2.5mol / L n-butyllithium n-hexane solution, and then drop Add 15.7 g (0.1 mol) of methyl 1-methylpiperidine-4-carboxylate, keep stirring at low temperature, monitor by TLC until the reaction is complete, and then add glacial acetic acid. The reaction solution was poured into purified water and stirred evenly, extracted with ethyl acetate, the organic layer was separated, dried by adding anhydrous sodium sulfate, filtered with suction, and the filtrate was concentrated under reduced pressure. The obtained oil was added with isopropanol and stirred to precipitate a solid, which was filtered and dried to obtain 25.3 g of an off-white solid with a yield of 85.1%. HPLC purity: 98.7%

[0034] 1H NMR 1H NMR(400MHz,C...

Embodiment 2

[0036] Preparation of [4-(1-methylpiperidine)][2-(1-phenethyl-1H-imidazole-)]methanone

[0037] Under the protection of nitrogen, dissolve 17.2g (0.1mol) of phenethylimidazole in 170mL tetrahydrofuran, stir and cool down to below -40°C, add dropwise 50mL (0.125mol) of 2.5mol / L n-butyllithium n-hexane solution, and dropwise , and then dropwise added 17.1 g (0.1 mol) of ethyl 1-methylpiperidine-4-carboxylate, kept stirring at low temperature, monitored by TLC until the reaction was complete, and then added glacial acetic acid. The reaction solution was poured into purified water and stirred evenly, extracted with ethyl acetate, the organic layer was separated, dried by adding anhydrous sodium sulfate, filtered with suction, and the filtrate was concentrated under reduced pressure. The obtained oil was stirred with isopropanol to precipitate a solid, which was filtered and dried to obtain 24.9 g of an off-white solid with a yield of 83.7% and an HPLC purity of 98.5%.

Embodiment 3

[0039] Preparation of [4-(1-methylpiperidine)][2-(1-phenethyl-1H-imidazole-)]methanone

[0040] Under the protection of nitrogen, dissolve 17.2g (0.1mol) of phenethylimidazole in 170mL tetrahydrofuran, stir evenly, cool down to below -40°C, add dropwise 50mL (0.125mol) of 2.5mol / L n-butyllithium n-hexane solution, Then 18.5 g (0.1 mol) of isopropyl 1-methylpiperidine-4-carboxylate was added dropwise, and stirring was continued at low temperature. TLC was monitored until the reaction was complete, and then glacial acetic acid was added. The reaction solution was poured into purified water and stirred evenly, extracted with ethyl acetate, the organic layer was separated, dried by adding anhydrous sodium sulfate, filtered with suction, and the filtrate was concentrated under reduced pressure. The obtained oil was stirred with isopropanol, and a solid was precipitated, which was filtered and dried to obtain 26.8 g of off-white solid, yield 90.1%, HPLC purity: 99.2%

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com