Liquid phase synthetic Zr<4+> doped bismuth fluoride lithium-ion battery positive electrode material and preparation method thereof

A lithium-ion battery, liquid phase synthesis technology, applied in battery electrodes, chemical instruments and methods, secondary batteries, etc., can solve problems such as unpredictable effects and complex parent action mechanism, and achieve low equipment requirements and excellent electrochemical performance. , to avoid the effect of side reaction products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

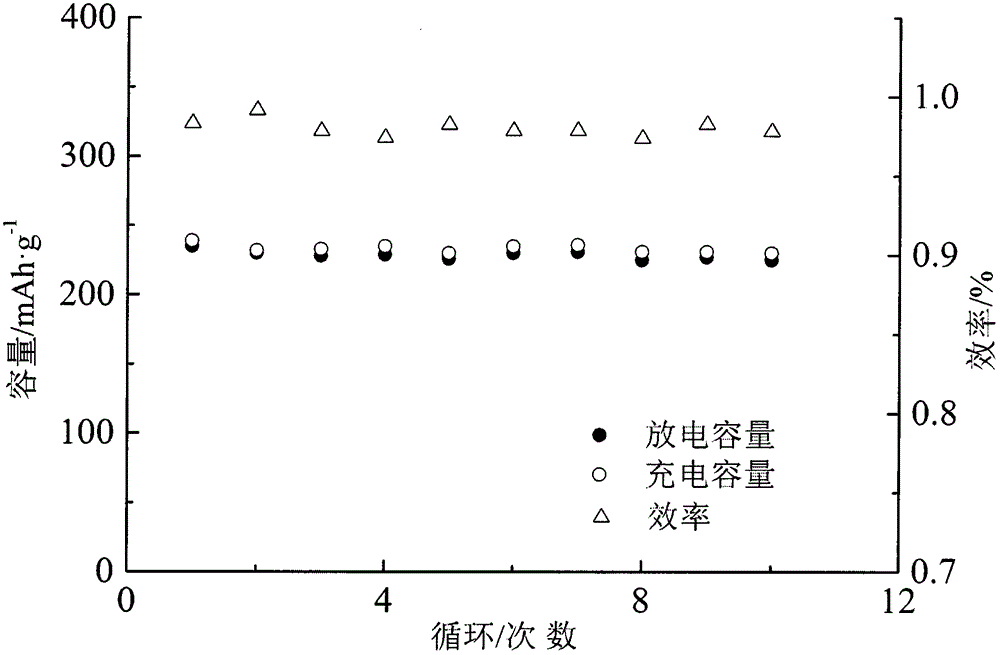

Examples

Embodiment 1

[0015]Embodiment 1: Ammonium fluoride is dissolved in the water of 4 times of the quality of ammonium fluoride, the quality 42% normal hexane of water, the dodecyl dimethyl hydroxypropyl sulfonate of 5.5% of the quality of water are added in this solution Base betaine, the n-butanol of the quality 5.6% of water; Insert mechanical stirring paddle in this system, stir 17 minutes with the speed of 1600rpm, after this leave standstill this solution 10 minutes and claim this solution as solution I; Pentahydrate nitric acid The amount of bismuth, bismuth nitrate pentahydrate 1.5% zirconium oxynitrate dihydrate, nitric acid 0.5% bismuth nitrate pentahydrate mass and perfluoroheptanoic acid 0.6% bismuth nitrate pentahydrate mass are mixed and dissolved in the total mass of the above substances after mixing In 4 times of water, add 40% n-hexane of the quality of water, 5% sodium lauryl aminopropionate of water, and 5% n-amyl alcohol of the quality of water in this solution; insert a mec...

Embodiment 2

[0016] Embodiment 2: ammonium fluoride is dissolved in the water of 4.5 times of ammonium fluoride quality, add the quality 50% n-hexane of water, the dodecyl dimethyl sulfopropyl beet of the quality 7% of water in this solution The quality 7% n-amyl alcohol of alkali, water; Insert mechanical stirring paddle in this system, stir 20 minutes with the speed of 1800rpm, leave standstill this solution after this 15 minutes and claim this solution as solution I; Bismuth nitrate pentahydrate, The amount of bismuth nitrate pentahydrate substance is 1.5% zirconium nitrate pentahydrate, nitric acid with 5% mass of bismuth nitrate pentahydrate and perfluoroheptanoic acid with 0.6% mass of bismuth nitrate pentahydrate, mixed and dissolved in 4 times the total mass of the above substances In water, add the normal hexane of the quality 40% of water, the quality 5% sodium cocoyl glutamate of water, the n-butanol of the quality 5% of water in this solution; Insert mechanical stirring paddle i...

Embodiment 3

[0017] Embodiment 3: Ammonium fluoride is dissolved in the water of 5 times of the quality of ammonium fluoride, the quality 58% n-hexane of water, the tetradecyl amidopropyl hydroxypropyl sulfo group of 9% of the quality of water are added in this solution Betaine, the n-hexanol of the quality 9.5% of water; Insert mechanical stirring paddle in this system, stir 30 minutes with the speed of 2000rpm, leave standstill this solution after this 20 minutes and claim this solution as solution I; Bismuth chloride, chlorine Zirconium sulfate tetrahydrate tetrahydrate with 5% bismuth content, nitric acid with 3.5% bismuth chloride mass and 2,2-difluorocyclopropanecarboxylic acid with 5% bismuth chloride mass are mixed and dissolved in 5 times the total mass of the above substances In water, add the normal hexane of the quality 60% of water, the quality 9% sodium lauroyl glutamate of water, the n-hexanol of the quality 9% of water in this solution; Stir at high speed for 30 minutes, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com