A kind of high bio-based content epoxy resin composition and its curing method and application

An epoxy resin and bio-based technology, applied in the direction of epoxy resin coatings, coatings, etc., can solve the problems of low crosslinking density of cured products, poor mechanical properties of cured products, complicated process, etc., to reduce human damage and easy to implement , the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

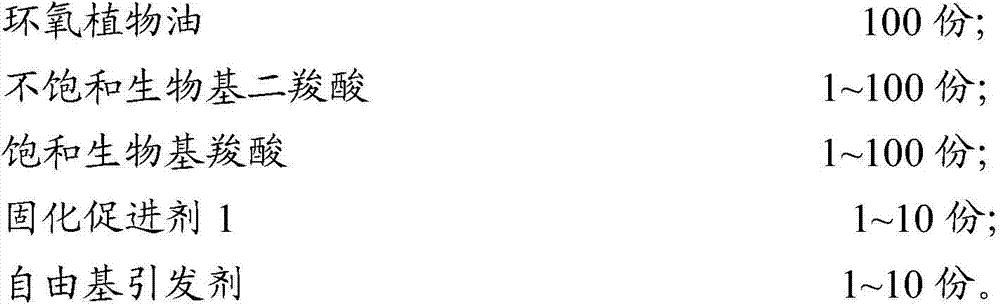

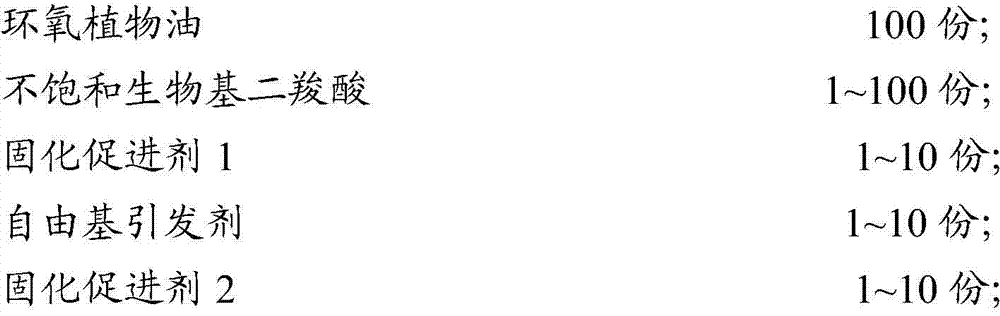

Method used

Image

Examples

Embodiment 1

[0040] 100g epoxidized soybean oil (Aladdin reagent), itaconic acid 35g (Aladdin reagent), malic acid 80g (Aladdin reagent), tetrabutylammonium bromide 1g (Sinopharm reagent), tert-butyl peroxybenzoate (Aladdin's Reagent) 10g mixed evenly, and applied on the cleaned tinplate, irradiated under 1000W high-temperature mercury lamp for 3 minutes, and cured to form a film. The glass transition temperature of this film is 85 ℃ (after the sample is solidified, grind into powder, test with the MET type differential scanning calorimeter that Mettler-Toledo company produces, N 2 atmosphere, the heating rate is 20°C / min, the same below).

Embodiment 2

[0042] With 100g epoxy castor oil (Aladdin's reagent), maleic acid 80g (Aladdin's reagent), citric acid 75g (Aladdin's reagent), triphenylphosphine 4g (National medicine reagent), tert-butyl peroxybenzoate (Aladdin's reagent) Latin reagent) 5g, mixed evenly, and applied on the cleaned tinplate, and irradiated for 3 minutes under a 1000W high-temperature mercury lamp to cure and form a film. The glass transition temperature of the film was 90°C.

Embodiment 3

[0044] 100g epoxidized soybean oil (Aladdin's reagent), itaconic acid 60g (Aladdin's reagent), triphenylphosphine 2g (National medicine reagent), tert-butyl peroxybenzoate (Aladdin's reagent) 8g, triethanolamine (National medicine Reagent) 5g, mixed evenly, and applied on the cleaned tinplate, irradiated under 1000W high-temperature mercury lamp for 3 minutes, and cured to form a film. The glass transition temperature of the film was 80°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com