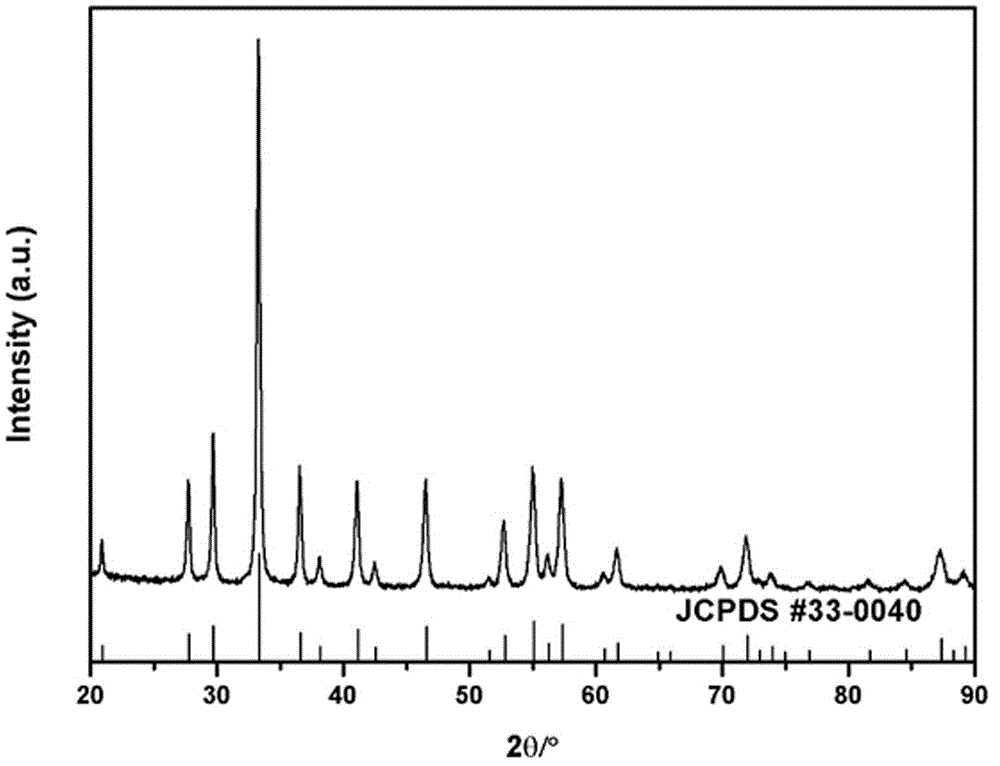

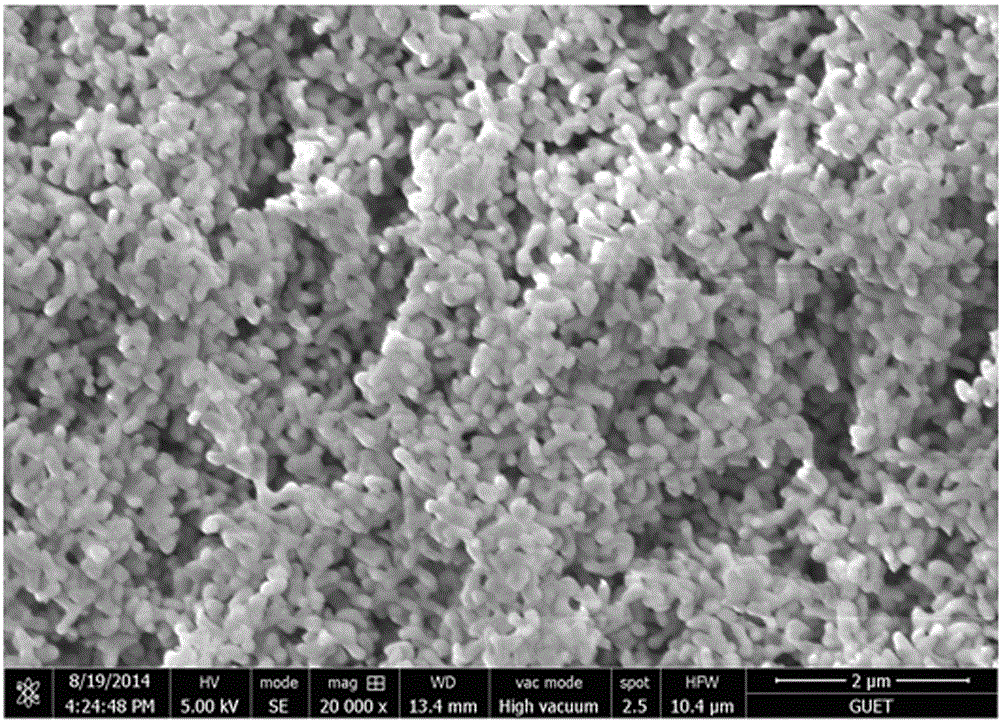

Method for preparing YAG-Ce phosphor by using combustion method

A fluorescent powder and combustion method technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, nano optics, etc., can solve problems such as toxicity and difficulty in complete combustion, and achieve lower reaction synthesis temperature and uniform distribution , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) First weigh 6.667g of aluminum chloride, 8.949g of yttrium chloride, and 0.186g of cerium chloride, the amount of which is controlled by the molar ratio: Y:Al:Ce=3:5:0.05, and the above mixed salt is mixed with 1.5 times its weight That is, 23.703g of LiCl is mixed and placed in a ceramic crucible, an appropriate amount of distilled water is added, and the crucible is placed in a water bath and heated to 80°C while stirring;

[0029] (2) Add 15.802g of starch into the crucible as a combustion agent, continue stirring until uniform, heat it in a muffle furnace to 300°C, keep it warm for 3 hours, and then calcinate the obtained sol at 800°C for 3 hours Take out after hours;

[0030] (3) Wash and remove LiCl in the precursor body until the conductivity of the rinse solution obtained by washing the fluorescent powder is 12 ps / cm and the pH is 7.0; after washing, filter with suction and dry in a drying oven at 80°C for 12 hours;

[0031] (4) Grind the dried precursor po...

Embodiment 2

[0034] (1) First take by weighing 6.667g aluminum chloride, 8.888g yttrium chloride, 0.260g cerium chloride, its consumption control molar ratio is: Y:Al:Ce=3:5:0.07; Mix the above-mentioned mixed salt with 31.63g Mix LiCl in a ceramic crucible, add an appropriate amount of distilled water, place the crucible in a water bath and heat it to 80°C while stirring;

[0035] (2) Add 15.82g of starch into the crucible, continue to stir until uniform, put it in a muffle furnace and heat it to 300°C for 3 hours, then heat the obtained sol at 800°C for 3 hours and take it out;

[0036] (3) Wash with dilute hydrochloric acid to remove LiCl in the precursor until the conductivity of the washing solution obtained by washing the fluorescent powder is 8 ps / cm, and when the pH is 6.9, the washing is completed, suction filtered, and placed in a drying oven at 80°C Dry for 12 hours;

[0037] (4) Grind the dried precursor powder and place it in a reducing atmosphere where the volume of hydrogen...

Embodiment 3

[0039] (1) First weigh 6.667g of aluminum chloride, 9.009g of yttrium chloride, and 0.111g of cerium chloride. The molar ratio of the dosage is: Y:Al:Ce=3:5:0.03, and the above mixed salt and 63.148g LiCl is mixed and placed in a ceramic crucible, and an appropriate amount of distilled water is added, and the crucible is placed in a water bath and heated to 80°C while stirring;

[0040] (2) Add 15.787g of starch into the crucible as a combustion agent, continue stirring until uniform, heat it in a muffle furnace to 300°C for 3 hours, and then calcinate the obtained sol at 800°C for 3 hours after taking out;

[0041] (3) Wash with water to remove LiCl in the precursor, until the conductivity of the rinse solution obtained by washing the phosphor is 13 ps / cm, and the pH is 7.1, after the washing is completed, suction filter and dry in an 80°C drying oven for 12 hours;

[0042] (4) Grind the dried precursor powder and place it in a reducing atmosphere with the volume of hydrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com