Preparation method of monodisperse porous silicon dioxide microspheres

A technology of porous silicon dioxide and silicon dioxide, applied in the direction of silicon dioxide, silicon oxide, nanotechnology for materials and surface science, etc., can solve the problems of many reactants, high biological toxicity, and complicated preparation process, etc. Achieve the effect of pure product, mild reaction conditions and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

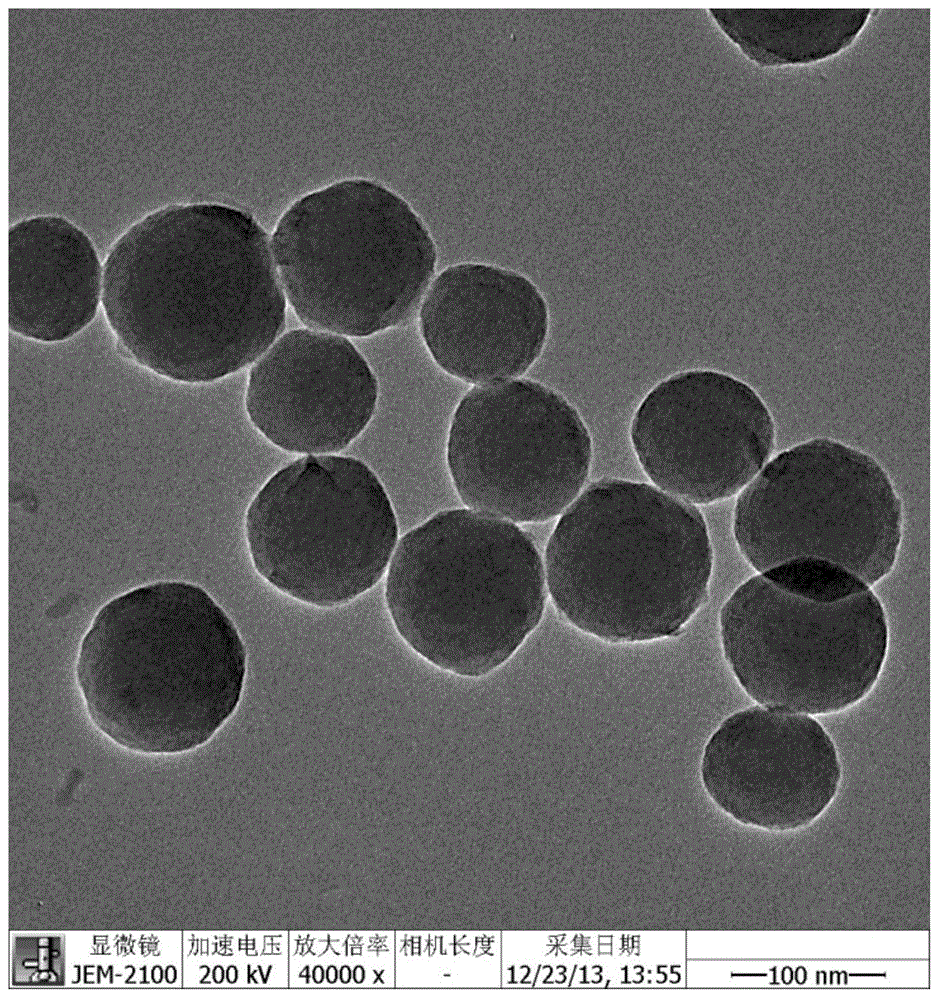

[0026] Add 5mL of ammonia water and 96mL of absolute ethanol into a single-necked flask, stir and mix evenly, and place in a 30°C water bath. After the temperature stabilizes, take 4mL of tetraethyl orthosilicate (TEOS) and 4mL of absolute ethanol, mix evenly, and then add dropwise , stirred at room temperature for 24h, the product was centrifuged and washed several times with absolute ethanol, and finally dried to obtain monodisperse solid silica microspheres, and its transmission electron microscope photo is as follows figure 1 As shown, it can be seen that the prepared solid silica microspheres have a complete structure, uniform size, and a particle size of about 70nm.

[0027] Take 0.5 g of the above-mentioned solid silica microspheres and 20 mL of deionized water and put them into a polytetrafluoroethylene-lined hydrothermal reaction kettle, and place them in a thermostat at 130°C for 12 hours. The product was taken out and centrifuged and washed several times with absolu...

Embodiment 2

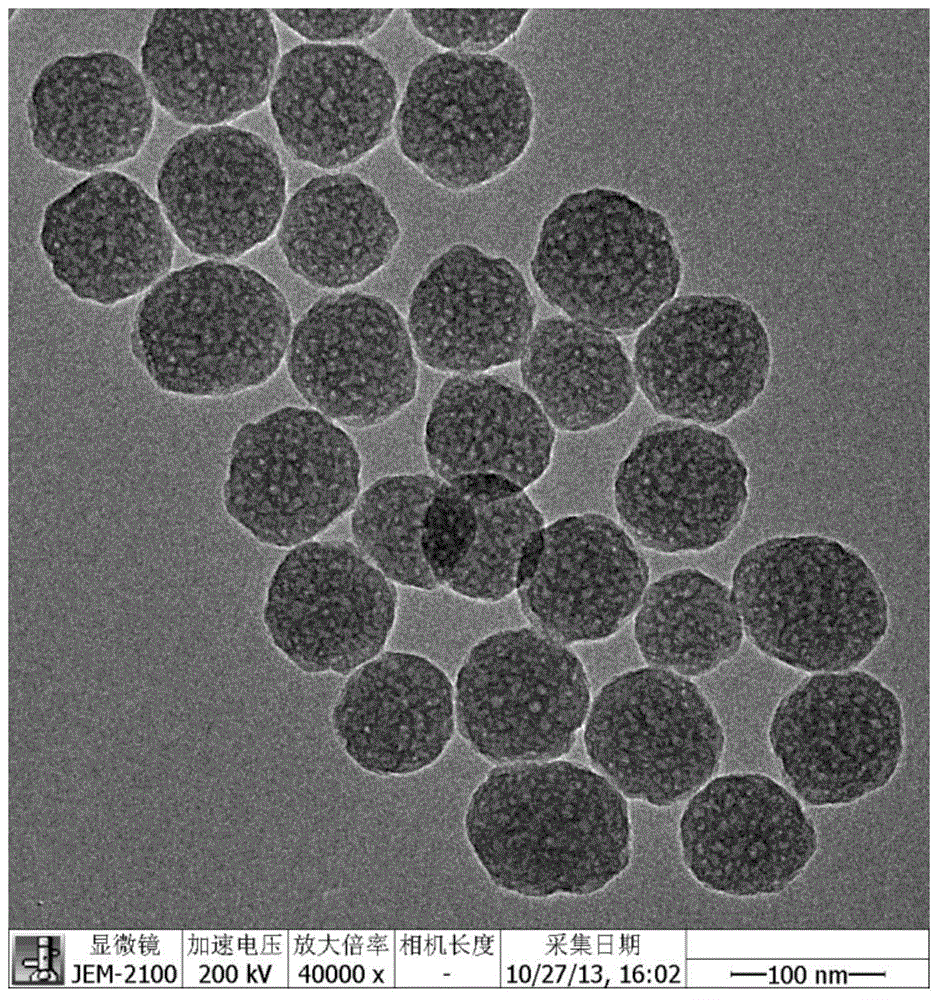

[0030] Take the mixed solution of 0.5g of solid silica microspheres obtained in step 1 of Example 1 and 20mL of deionized water and absolute ethanol, and add it to a hydrothermal reaction kettle with a polytetrafluoroethylene liner, and place it in a 120°C Stand in the incubator for 18h. The product was taken out and centrifuged, washed several times with absolute ethanol, and dried to obtain a monodisperse porous silica microsphere material. Wherein the volume ratio of deionized water and absolute ethanol is 2:1. The micropores on the prepared porous silicon dioxide microspheres are evenly distributed, and the pore size is about 12 nm.

[0031] In this example, absolute ethanol was added during the hydrothermal reaction, because ethanol has a better dissolving effect on silicon dioxide, so the dual effects of ethanol and water in the high temperature and high pressure reaction environment lead to the final formation of porous The pores of silica become larger.

Embodiment 3

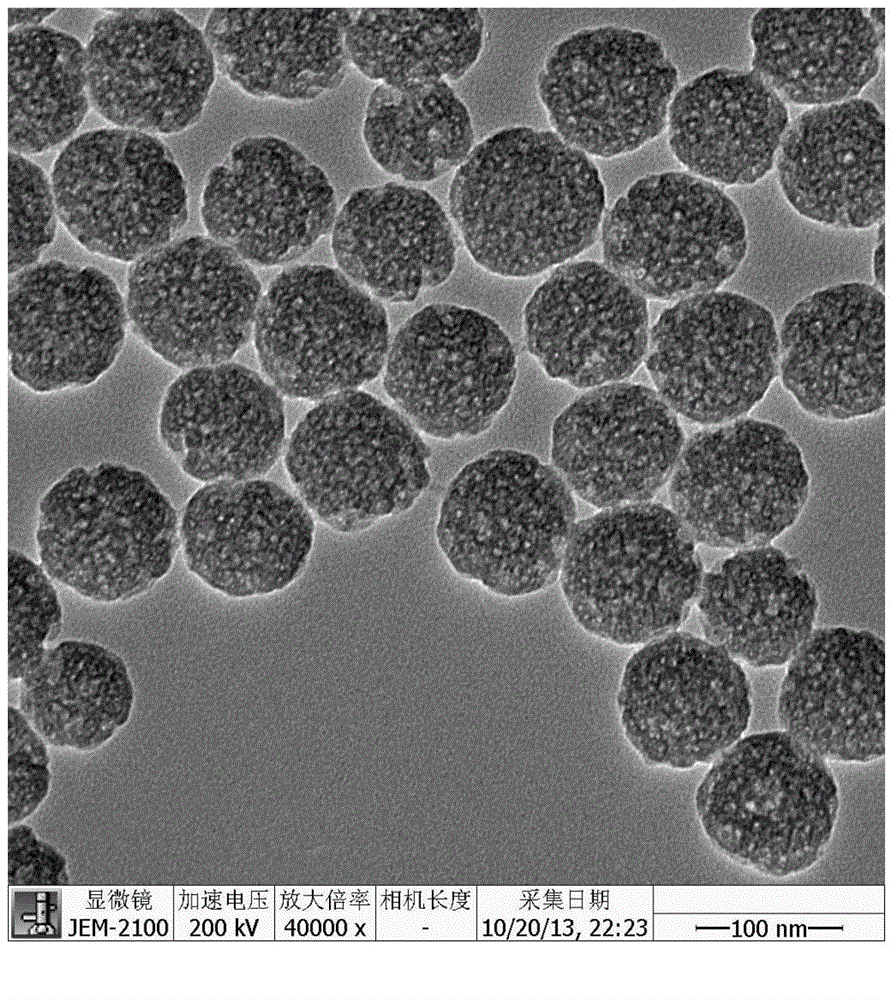

[0033] The aqueous solution of 0.5 g of solid silica microspheres and 20 mL of water-soluble polymer obtained in step 1 in Example 1 was added to a hydrothermal reaction kettle lined with polytetrafluoroethylene, and placed in a constant temperature box at 100 ° C. Set 20h. The product was taken out and centrifuged, washed several times with absolute ethanol, and dried to obtain a monodisperse porous silica microsphere material. The aqueous solution of the water-soluble polymer is prepared by mixing 0.05 g of polyvinylpyrrolidone (PVP) with deionized water.

[0034] The prepared porous silica microsphere transmission electron microscope photograph is as follows image 3 As shown, it can be seen that the distribution of micropores is uniform, and the pore size is about 20 nm. In this embodiment, since the addition of PVP can penetrate into the interior of the silica during hydrolysis, more nanoparticles are removed, resulting in further enlargement of the pores of the final p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com