Preparation method of porous low-dielectric polyimide thin films

A technology of polyimide film and low dielectric is applied in the field of organic film preparation, which can solve the problems of high cost and complicated production of polyimide film, and achieve the effect of simple and easy-to-obtain raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

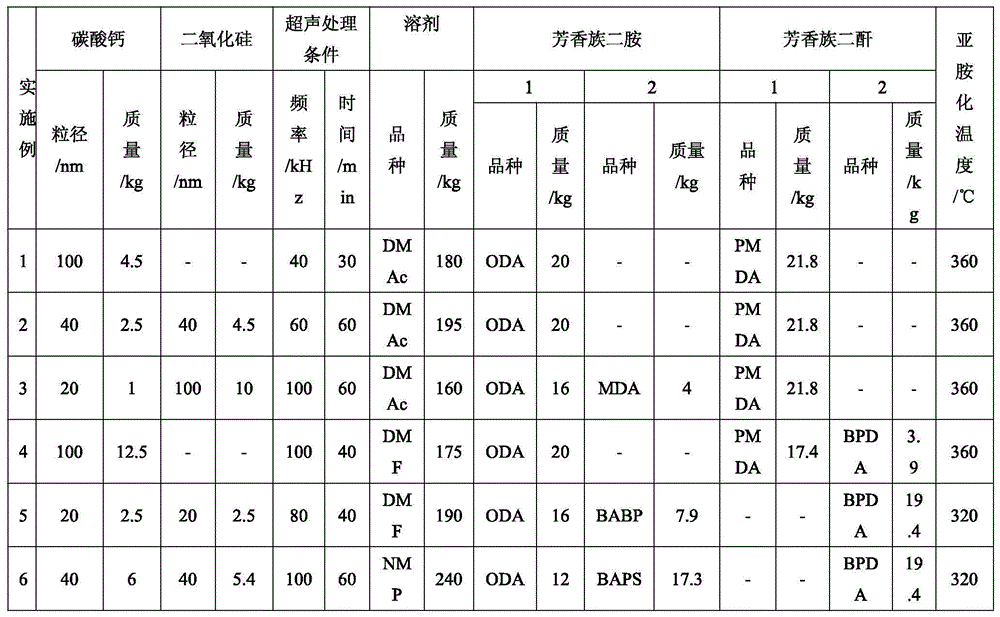

Examples

Embodiment 1

[0030] (1) Preparation of calcium carbonate suspension

[0031] Adopt Shanxi Ruicheng Warner Nano Material Co., Ltd. to produce 4.5kg of nano-calcium carbonate with a particle size of 100nm, add it into the aprotic solvent DMAc, under the condition of 40kHz ultrasonic dispersion, stir at a speed of 2000r / min, fully stir for 30min, and make a stable Suspension, ensure that the mass concentration of calcium carbonate suspension is 5%.

[0032] (2) Preparation of polyamic acid composite solution

[0033] Add the suspension obtained above into the polyamic acid polymerization reactor, add a sufficient amount of solvent, control the temperature at 40°C, add 20kg of ODA, and carry out mechanical stirring. After it is completely dissolved, control the temperature at 60°C, divide Add 21.8 kg of PMDA in an equimolar ratio to diamine in small batches, and keep stirring to fully react the diamine and dianhydride to form a polyamic acid composite solution with stable viscosity. The mass...

Embodiment 2

[0039] (1) Preparation of calcium carbonate and silica suspension

[0040] Adopt Shanxi Ruicheng Warner Nano Material Co., Ltd. to produce 2.5kg of nano-calcium carbonate with a particle diameter of 40nm, and 4.5kg of nano-silicon dioxide (produced by West Asia Reagent) with a particle diameter of 40nm, add in the aprotic solvent DMAc, and disperse with 60kHz ultrasonic waves Under the conditions, the stirring speed is 3000r / min and the mixture is fully stirred for 60min to form a stable suspension, ensuring that the mass concentration of nano-calcium carbonate and silicon dioxide is 20%.

[0041] (2) Preparation of polyamic acid composite solution

[0042]Add the suspension obtained above into the polyamic acid polymerization reaction kettle, add solvent, control the temperature at 10°C, add 20kg of ODA, and carry out mechanical stirring. After it is completely dissolved, control the temperature at 50°C, batch by batch Add 21.8 kg of PMDA in an equimolar ratio to the diamine...

Embodiment 3

[0048] (1) Preparation of calcium carbonate and silica suspension

[0049] Adopt Shanxi Ruicheng Warner Nano Material Co., Ltd. to produce 1kg of nano-calcium carbonate with a particle diameter of 20nm and 10kg of nano-silicon dioxide (produced by West Asia Reagent) with a particle diameter of 100nm, add in 160kg of aprotic solvent DMAc, 100kHz ultrasonic dispersion conditions Under 2000r / min stirring speed, fully stirred for 60min to make a stable suspension, ensuring that the mass concentration of calcium carbonate and silicon dioxide is 15%.

[0050] (2) Preparation of polyamic acid composite solution

[0051] Add the suspension obtained above into the polyamic acid polymerization reactor, add a sufficient amount of solvent, control the temperature at 25°C, add 16kg of ODA and 4kg of MDA, and perform mechanical stirring. After it is completely dissolved, control the temperature at 25°C. At 55°C, add 21.8 kg of PMDA in an equimolar ratio to diamine in batches, and keep stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com