Biological preparation method of agmatine sulfate

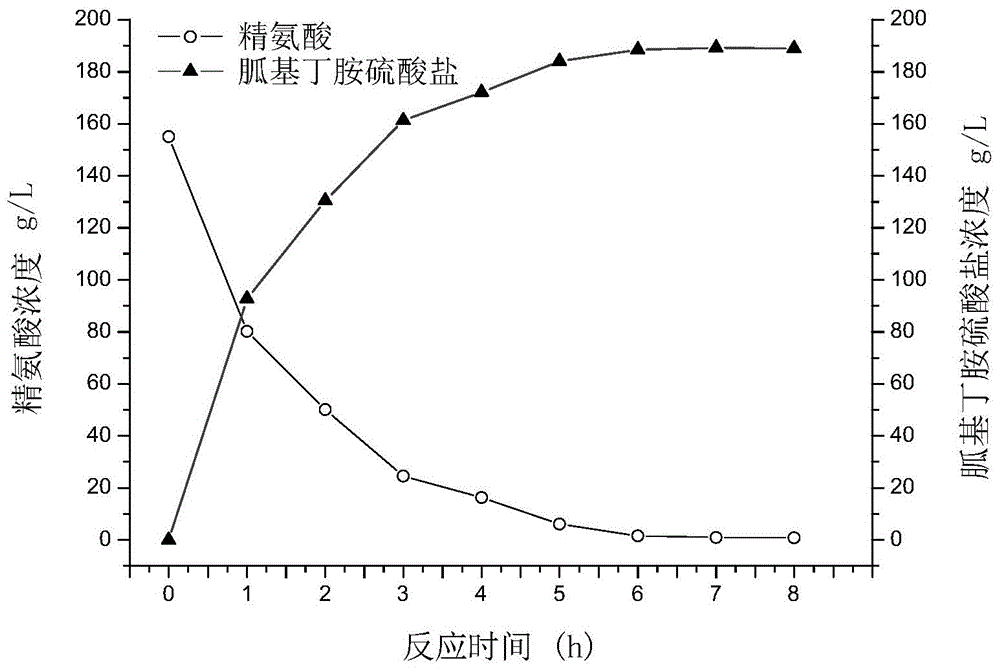

A technology for agmatine sulfate and biological preparation, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the environmental pollution of agmatine sulfate and the lack of agmatine sulfate Seeing and unfavorable for energy saving and emission reduction of enterprises, achieving the effect of low cost, high production efficiency and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Small-scale preparation process of recombinant L-arginine decarboxylase

[0022] (1) Pilot fermentation of recombinant L-arginine decarboxylase

[0023] Take the 5L fermentation charge in a 7L small fermentation tank as an example:

[0024] Spread the recombinant E. coli glycerol tube or oblique interview tube containing the L-arginine decarboxylase gene in an LB agar oblique interview tube, and the medium contains 100 mg / L kanamycin. Activate and culture at 37°C for 13h. Add 6 mL of sterile normal saline to the cultured LB oblique tube to make a bacterial suspension. Take 1 mL of the bacterial suspension into a 100 mL TB shake flask seed solution, and add 10 mg of kanamycin at the same time. The seed liquid was cultivated to OD at 35℃, 220rpm shaker 600 When it reaches 4 to 5, it is connected to 5L TB fermentation broth. The culture conditions are as follows: Inoculation volume: 100mL / 5L (2.0%); Ventilation volume: 1vvm (5 L / min); Tank pressure: 0.04MPa; Stirri...

Embodiment 2

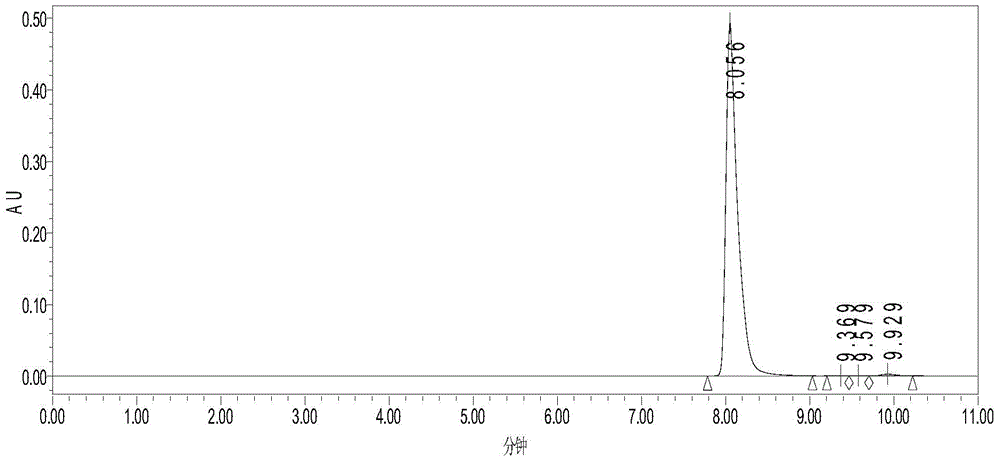

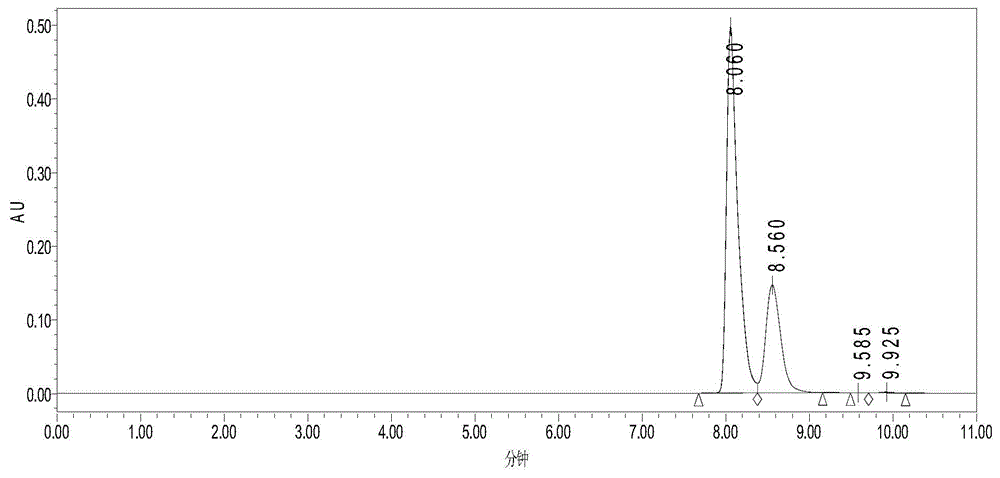

[0026] Example 2: Reaction monitoring method

[0027] HPLC method for detecting substrates and products: quickly dilute the reaction solution 250 times with frozen deionized water to terminate the enzymatic reaction, mix well and filter it with a 0.45μm microporous membrane, and wait for sample injection. Chromatographic conditions are: HILIC amino column: 3μm, 100?, 250mm×4.6mm; mobile phase: water (pH adjusted to 2.5 by phosphoric acid); flow rate: 0.5mL / min; column temperature: 35°C; detection wavelength: 205nm; sample injection Quantity: 10μL. The specific map is shown in the attached drawings of the manual Figure 2 ~ Figure 6 .

Embodiment 3

[0028] Example 3: Enzyme activity verification method

[0029] Preparation of citric acid phosphate buffer solution with pH 6.0: 2g citric acid monohydrate, 12g Na 2 HPO 4 ·12H 2 Dissolve O in deionized water and dilute to 200 mL, set aside. Preparation of 10g / 99mL arginine sulfate buffer solution: Dissolve 10g arginine in 50mL pH 6.0 citrate phosphate buffer solution and adjust the pH to about 6.0 with sulfuric acid (40%, V / V), and continue to use pH The volume of 6.0 citrate phosphate buffer solution is adjusted to 99mL. Add 99mL of the above-mentioned arginine sulfate buffer solution, 0.02g of coenzyme PLP (pyridoxal phosphate), 1mL of wet bacteria concentration of 1g / 10mL of crude enzyme solution after breaking the wall into a 250mL reaction flask, 150rpm water bath shaker 30 After shaking the reaction at ℃ for 5 minutes, when the arginine content is reduced by about 20g / L by HPLC, it can be judged that the enzyme can be used for normal production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com