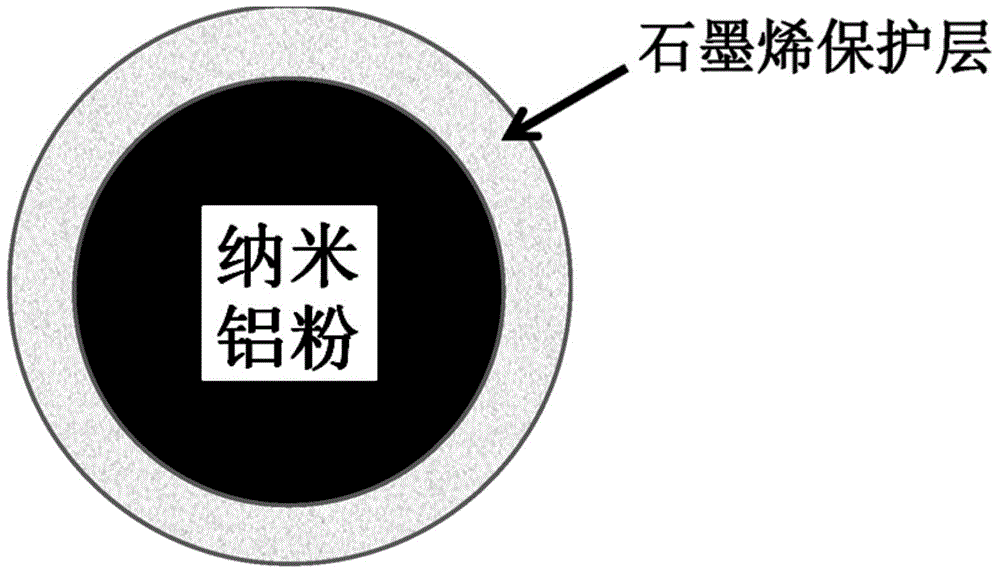

Method for industrially preparing graphene coated aluminum nanopowders

A nano-aluminum powder, graphene technology, applied in metal processing equipment, transportation and packaging, etc., can solve problems such as no solution, achieve the effect of simple modification method, prevent oxidation, and solve surface oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

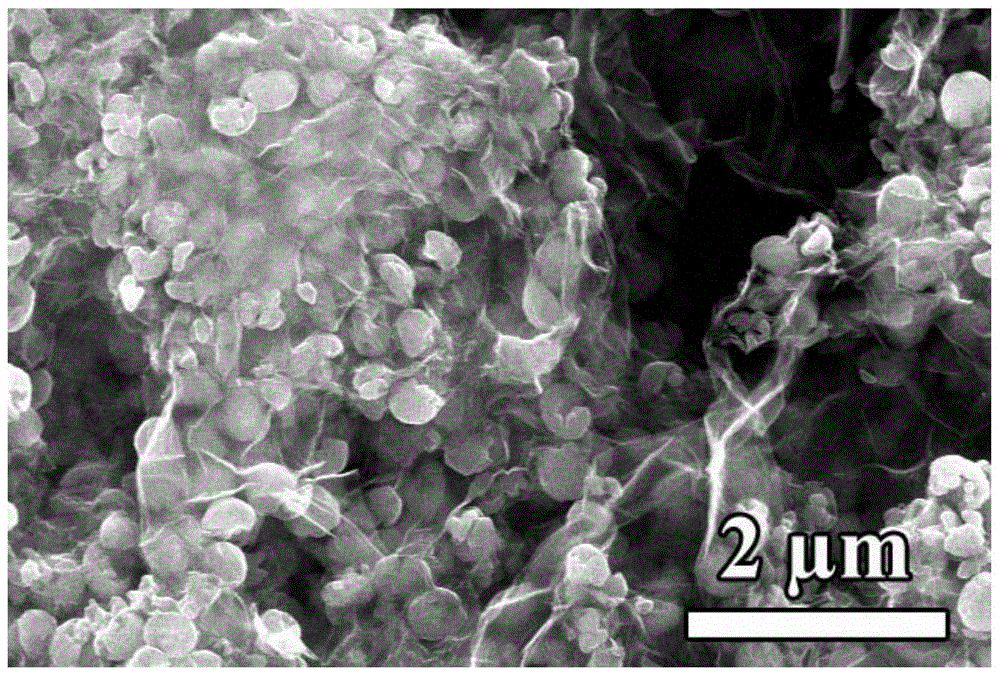

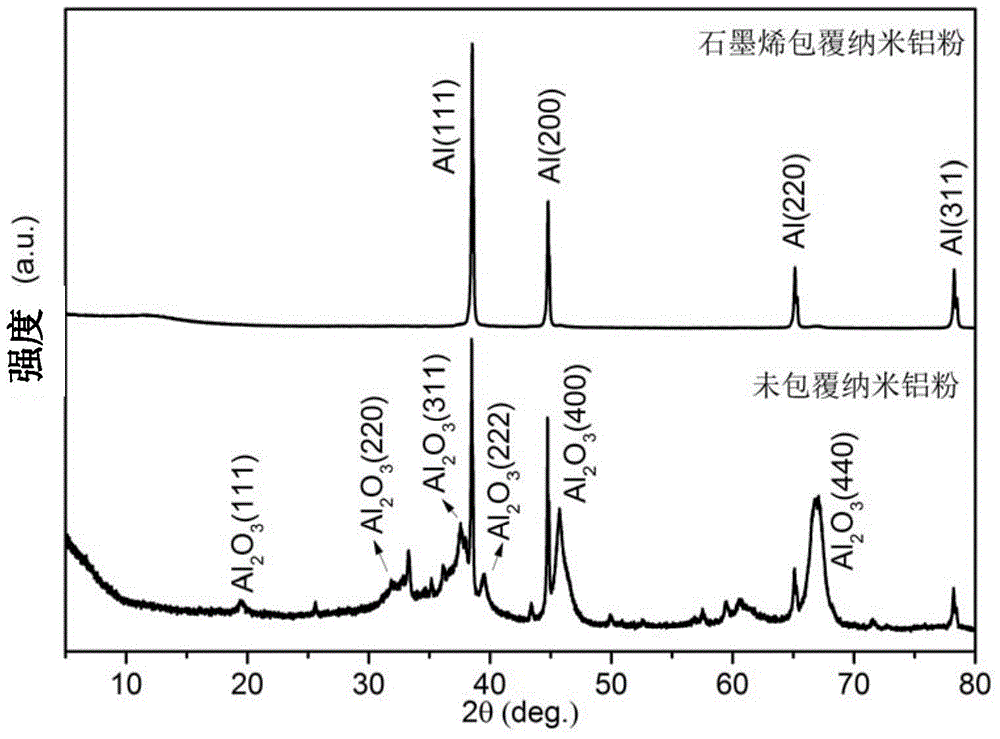

Image

Examples

Embodiment 1

[0041] The present embodiment provides a kind of method of graphene coating nano-aluminum powder, and this method comprises the following steps:

[0042] (1) Preparation and dissolution of graphene

[0043] Graphene is prepared by the traditional Hummers method, which specifically includes the following steps:

[0044] Install the round-bottomed reaction bottle in an ice-water bath, add an appropriate amount of concentrated sulfuric acid, and add a mixture of 4g graphite powder and 2g sodium nitrate under stirring;

[0045] Add 15g of potassium permanganate in portions, stir quickly and control the reaction temperature not to exceed 20°C, raise the temperature to about 35°C, continue to stir for 30min, then slowly add an appropriate amount of deionized water, after stirring for 20min, add an appropriate amount of hydrogen peroxide to reduce the residual oxidant, Turn the solution into bright yellow;

[0046] Filtrate while hot, and be that the HCl solution of 5wt% and deioni...

Embodiment 2

[0057] The present embodiment provides a kind of method of graphene coating nano-aluminum powder, and this method comprises the following steps:

[0058] (1) Preparation and dissolution of graphene

[0059] Graphene adopts traditional Hummers method to prepare, and concrete method is with embodiment 1;

[0060] Then 5mg of graphene was added into polyacrylic acid aqueous solution (200mL) and stirred rapidly (500r / min) to prepare a graphene dispersion, and it was vacuumized to remove dissolved air in the liquid.

[0061] (2) Graphene-coated nano-aluminum powder

[0062] In the glove box, add 20 mg of nano-aluminum powder at a rate of 2 mg / min to the prepared 100 mL graphene dispersion, and stir rapidly (2000 r / min) to form a crude product, and vacuumize it to remove dissolved air in the liquid , wherein the nano-aluminum powder needs to be treated with dilute hydrochloric acid or sodium hydroxide before adding the graphene mixture to ensure the complete removal of the passiva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com