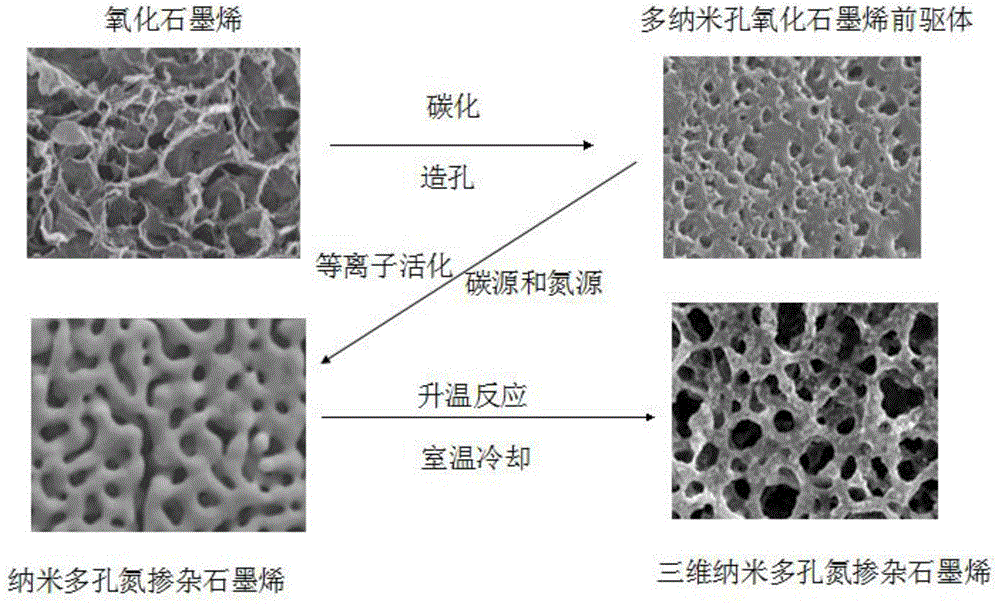

Method for growing three-dimensional nitrogen-doped graphene by taking nanoporous graphene as substrate

A nitrogen-doped graphene and graphene technology, applied in nanotechnology and other directions, to achieve the effects of excellent electrochemical performance, uniform distribution, and uniform pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

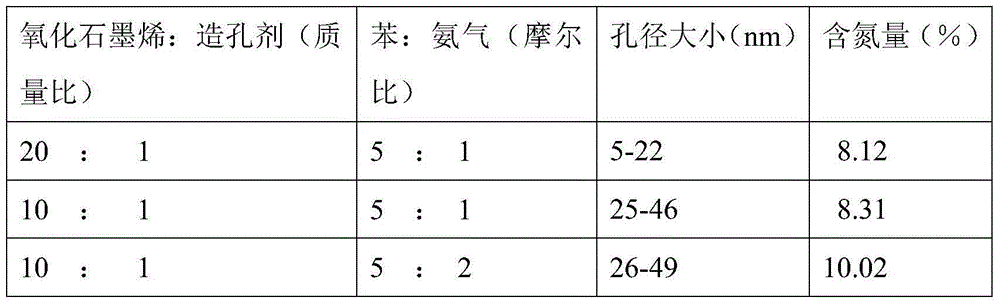

[0034] (1) 100 mg of graphene oxide and 5 mg of phosphoric acid prepared by the improved hummers method are added to 100 ml of 95% dehydrated alcohol and fully dispersed into a dispersion;

[0035] (2) Place the dispersion prepared in step (1) in an atmosphere of nitrogen and argon, and control the flow rate of nitrogen and argon to be 100L / h; heat up the dispersion at a rate of 10°C / min, at 2000°C After lower carbonization treatment for 50 hours, a multi-nanoporous graphene oxide precursor is obtained;

[0036] (3) the carbonized multi-nanoporous graphene oxide precursor in step (2) is activated in the plasma flow of argon and hydrogen, and feeds benzene and ammonia, and the flow rate of argon and hydrogen is 120L / h ; The concentrations of benzene and ammonia gas were added to be 0.5mol / L and 0.1mol / L respectively; Nitrogen-doped graphene was grown by vapor phase deposition at a temperature of 700°C, and the plasma was withdrawn after 10 minutes of reaction;

[0037] (4) The...

Embodiment 2

[0039] (1) Graphene oxide 100mg and 10mg ethyl silicate prepared by the improved hummers method are added to 95% dehydrated alcohol 100ml and fully dispersed into a dispersion;

[0040] (2) Place the dispersion prepared in step (1) in an atmosphere of nitrogen and argon, and control the flow rate to 100L / h; heat up the dispersion at a rate of 10°C / min, and carbonize it at 2500°C 50h, obtain the graphene oxide precursor of many nanopores;

[0041] (3) the carbonized multi-nanoporous graphene oxide precursor in step (2) is placed in the plasma flow of argon and hydrogen for activation, and feeds benzene and ammonia, and the flow rate of argon and hydrogen is 120L / h: Add benzene and ammonia at concentrations of 0.5 mol / L and 0.2 mol / L respectively, grow nitrogen-doped graphene by vapor deposition at 700°C, react for 10 minutes, and withdraw from the plasma;

[0042] (4) The product obtained in step (3) is subjected to heating and cooling treatment: start to cool down to 100° C....

Embodiment 3

[0044] (1) Add 100 mg of graphene oxide and 10 mg of boric acid prepared by the improved hummers method to 100 ml of deionized water and fully disperse into a dispersion;

[0045] (2) Place the dispersion prepared in step (1) in an atmosphere of nitrogen and argon, control the flow rate to 100L / h; heat up at a rate of 10°C / min, and carbonize at 2000°C for 50h to obtain multi-nano Porous graphene oxide precursors;

[0046] (3) The carbonized multi-nanoporous graphene oxide precursor in step (2) is placed in a hydrogen plasma flow for activation, and in argon, benzene and ammonia are passed into the hydrogen flow, and the argon flow rate is 120L / h , the hydrogen flow rate is 120L / h; the concentrations of benzene and ammonia are 0.5mol / L and 0.3mol / L respectively; nitrogen-doped graphene is grown by vapor deposition at 600°C, and the plasma is withdrawn after 10 minutes of reaction;

[0047](4) The product obtained in step (3) is subjected to heating and cooling treatment: start...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com