Cadmium-arsenic absorbing material and preparing method and application thereof

An adsorption material and application technology, applied in the field of soil pollution remediation, can solve the problem that the simultaneous removal ability of arsenic and cationic metal pollutants is not considered, the simultaneous removal ability of cationic metal pollutants is not considered, and the adsorption material arsenic removal efficiency is poor. and other problems to achieve the effect of reducing the risk of secondary dissolution, improving the physical and chemical properties of soil, reducing safety risks and human health hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

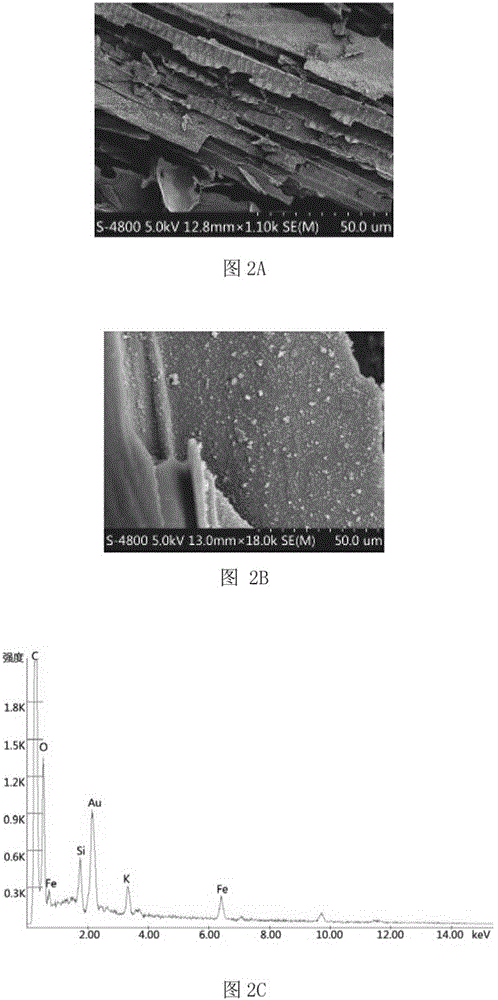

[0032] Example 1 Preparation of different modified adsorption material samples and comparison of their adsorption properties

[0033] Collect rice straw, pulverize it with a particle size of <10cm, rapidly heat up to 500°C at a rate of 30°C / min under oxygen-limited conditions, thermally crack until complete carbonization, cool naturally to room temperature, and crush through a 10-mesh sieve to obtain the precursor of the adsorption material , and then mixed with ferric chloride solution at a solid-to-liquid ratio of 1g:40mL, wherein the mixed mass percentages of the adsorbent material precursor and iron are 100:0, 99:1, 49:1, 19:1, and 9:1 , stirred and mixed for 12 hours, then reacted at 120°C for 12 hours, cooled naturally to room temperature, washed with water to remove the residual free iron salt on the surface of the material, dried at 80°C, crushed through a 10-mesh sieve, and obtained five different cadmium and arsenic adsorption Material.

[0034] Wherein the mixed ...

Embodiment 2

[0040] Example 2 Adsorbent material C's removal ability test for cadmium and arsenic present in complex

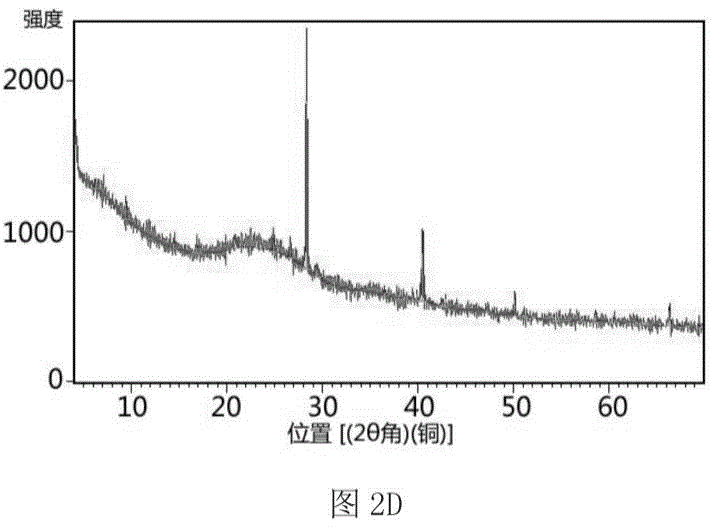

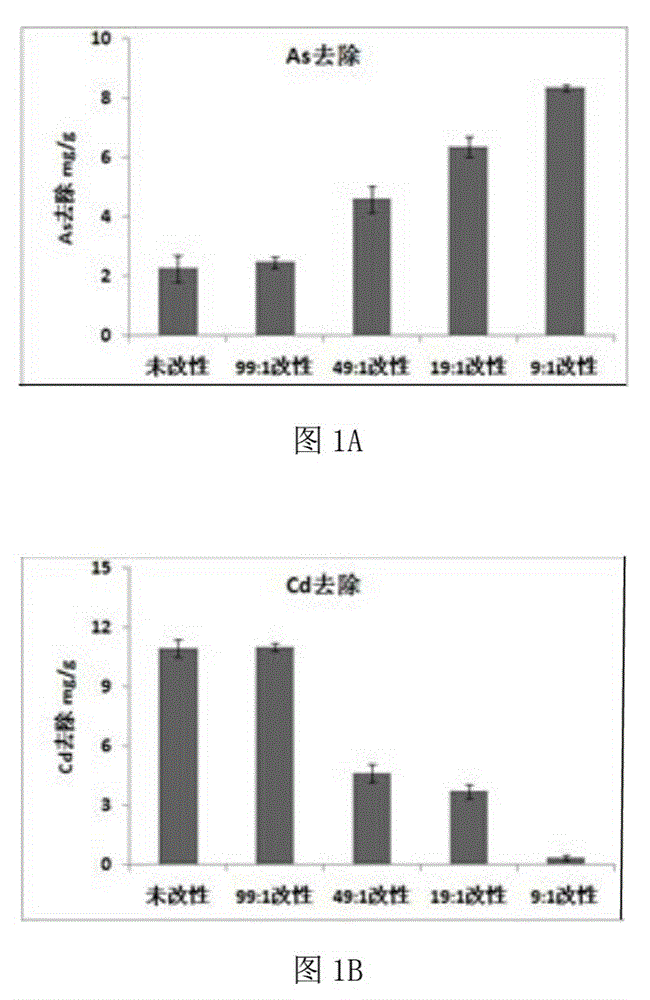

[0041] The adsorption material C was analyzed by scanning electron microscopy, EDS energy spectrum scanning and XRD diffraction, see Figure 2A , 2B , 2C, 2D. 2A and 2B are the surface morphology maps of the adsorption material C. It can be found that iron particles are loaded on the surface of the carbon-based cadmium-arsenic adsorption material, and the size is about 1-5nm. At the same time, the results of 2C energy spectrum scanning also prove that the adsorption material C contains a certain amount of Fe element. Furthermore, multiple diffraction peaks related to the iron mineral goethite were also observed in the 2D XRD diffraction results.

[0042] The adsorption material C is evaluated for the removal ability of cadmium and arsenic in complex existence: by adding 10g / L adsorption material to the configured metal pollution solution (containing 100mg / L arsenate a...

Embodiment 3

[0043] Example 3 Adsorbent material B is tested for the removal capacity of cadmium and arsenic present in complex

[0044] The adsorption material B is evaluated for the removal ability of cadmium and arsenic in complex existence: add 10g / L adsorption material B to the polluted solution (containing 100mg / L arsenate and 100mg / L cadmium ions), and finally the adsorption material B has no effect on the removal of arsenic. The adsorption capacity reaches 4.0 mg / g, and the adsorption capacity for cadmium can also reach 6.6 mg / g, while the same dose of adsorption material A can only remove 0.8 mg / g arsenic and 10.4 mg / g cadmium at the same time, lacking the removal of arsenic capacity, the same dose of adsorption material D can only remove 8.0 mg / g arsenic and 3.3 mg / g cadmium at the same time, lacking the ability to remove cadmium; Adding 10g / L of adsorption material to the medium, the adsorption capacity of the adsorption material to arsenic can reach 5.8mg / g, and the adsorptio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grinding particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com