Solid acid catalyst and application thereof to synthesis of reproducible diesel oil or aviation kerosene

A solid acid catalyst, catalyst technology, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, preparation of liquid hydrocarbon mixtures, etc. The effect of high substrate universality, cheap and easy-to-obtain raw materials, and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~84

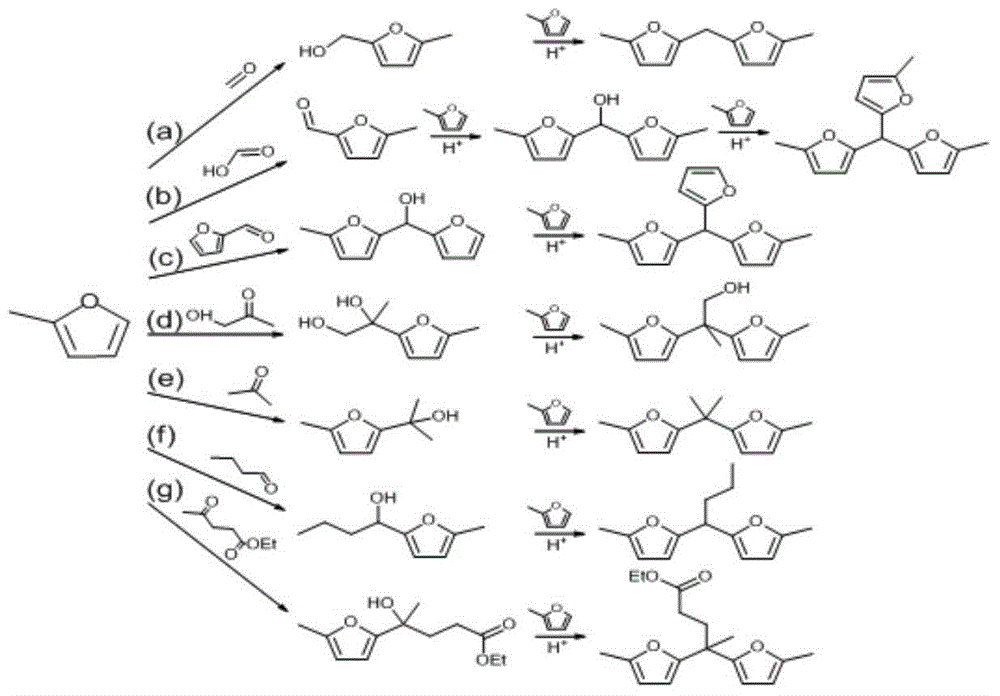

[0018] Resin precursor made by condensation reaction

[0019] Sodium lignosulfonate is dissolved in water, and its mass concentration is controlled to be 10-40%. Then add the crosslinking agent dropwise in the sodium lignosulfonate solution and control the amount ratio of the crosslinking agent and sodium lignosulfonate to be 5-30mmol 交联剂 / g 木质素磺酸钠 . The carbonyl compound used as the crosslinking agent is one or two or more of formaldehyde, formic acid, acetaldehyde, butyraldehyde, furfural, glucose and levulinic acid. After the two are mixed uniformly, the acid solution is added dropwise to the mixture, and the hydrogen ion concentration in the final mixture is controlled to be 1-5 mol / L. Inorganic acid is one or more of sulfuric acid, hydrochloric acid, nitric acid, perchloric acid, phosphoric acid, phosphotungstic acid, phosphomolybdic acid; organic acid is trifluoromethanesulfonic acid, trifluoroacetic acid, methanesulfonic acid, p-toluene One or more of sulfonic acid,...

Embodiment 85-102

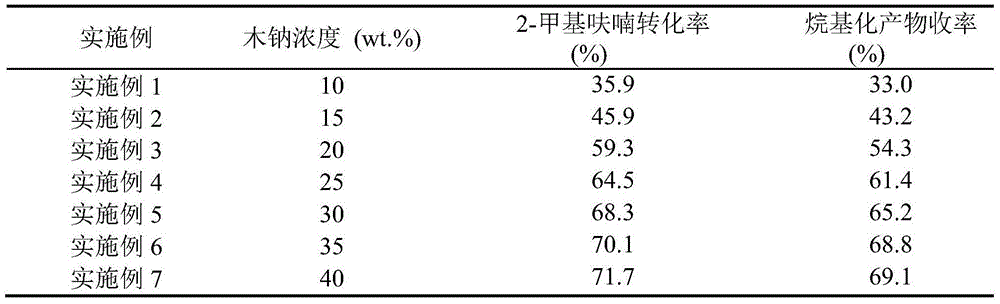

[0064] Evaluation of Reactivity of 2-Methylfuran and Formaldehyde

[0065] The catalyst evaluation of the present invention is carried out in a round bottom flask equipped with a condensing reflux device, and the temperature is controlled by a constant temperature water bath. The experimental process is as follows: add a certain mass of acidic resin catalyst, 3.28 grams of 2-methylfuran (40 mmol), and 0.6 grams of formaldehyde (20 mmol) into a 50 mL round bottom flask, and react at a certain temperature for a certain period of time. The reaction products were quantitatively analyzed by high performance liquid chromatography (HPLC).

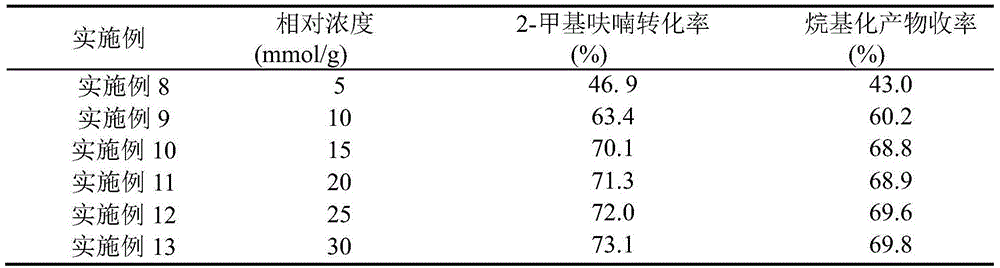

[0066] In each embodiment, the synthesis condition of acidic resin catalyst used is: a certain quality of sodium lignosulfonate is dissolved in water of a certain quality, the mass concentration of control sodium lignosulfonate is 35%, then to lignosulfonate Add a certain amount of formaldehyde cross-linking agent in sodium acid sodium solution, ...

Embodiment 103~120

[0086] 1) Activity comparison at different reaction temperatures, activity evaluation results are shown in Table 14.

[0087] Table 14. Effect of different reaction temperatures on catalytic activity

[0088]

[0089] Note: In the example, the amount of catalyst used is 0.15 g, the amount of reactants used is 3.28 g of 2-methylfuran (40 mmol), 0.92 g of formic acid (20 mmol), and the reaction time is 2 hours.

[0090] The experimental results in Table 14 show that as the reaction temperature increases, the activity of the catalyst increases gradually, but there are many side reactions in this reaction, and the selectivity of monopolymerization, dimerization, and trimerization of alkylated products is not high.

[0091] 2) Effect of catalyst dosage on catalytic activity, the reaction results are shown in Table 15.

[0092] Table 15. Effect of catalyst dosage on catalytic activity

[0093]

[0094]

[0095] Note: The amount of reactants in the example is 3.28 g of 2-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com