Saccharomyces cerevisiae of overexpression MIG1 genes and preparing method and application of saccharomyces cerevisiae

A kind of Saccharomyces cerevisiae, overexpression technology, applied in biological field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1, the preparation of a kind of xylose metabolism engineering bacterium ZQ5-OE035

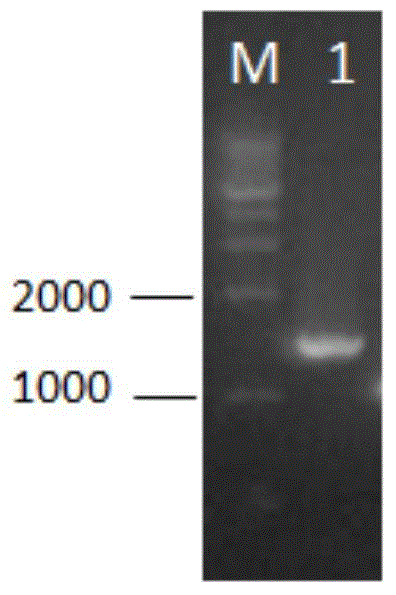

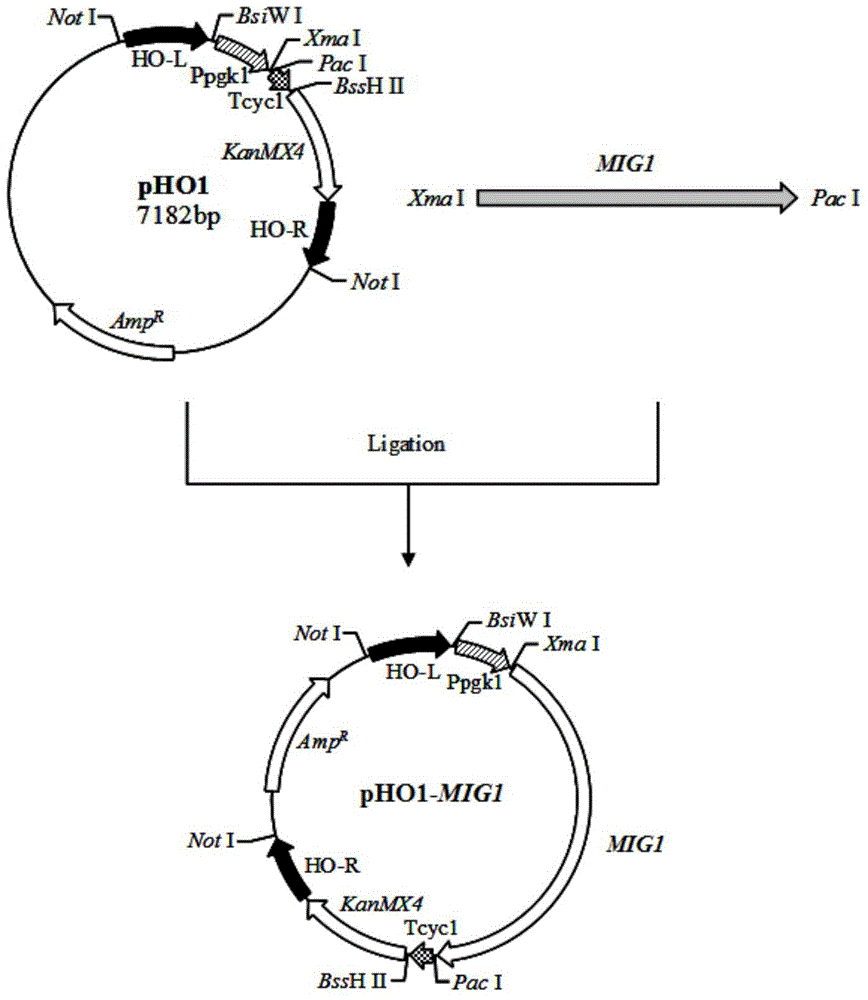

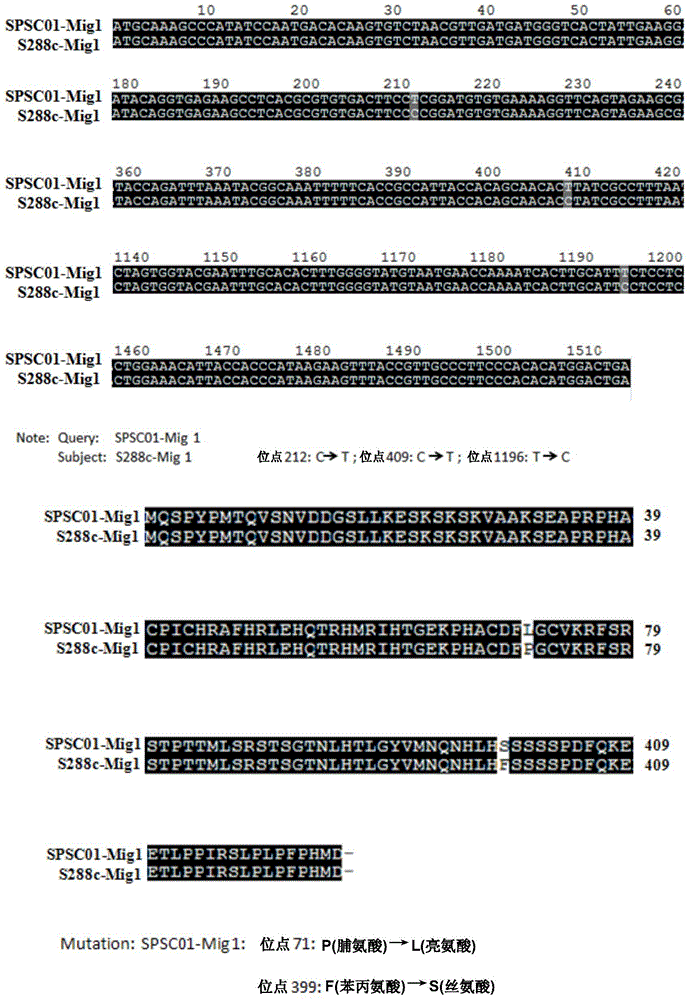

[0042] Step 1 Construct HO-MIG1-SPSC01 expression vector

[0043] 1.1 Extraction of genomic DNA from flocculating yeast SPSC01

[0044] (1) SPSC01 bacteria (CGMCC No.0587, Bioprocess Engineering Laboratory, School of Life Sciences, Dalian University of Technology) cultured in YPD medium overnight (30°C, 150rpm) was centrifuged (12000rpm, 5min) to collect cells.

[0045] (2) Add 0.1mol / L sodium citrate buffer solution to deflocculate the SPSC01 bacteria and shake evenly.

[0046] (3) Wash the cells twice with sterile water, centrifuge (12000 rpm, 5 min), and collect the cells.

[0047] (4) Resuspend the cells with an appropriate amount of lysate (0.1mol / L Tris-hydrochloric acid, pH 8.0; 50mmol / L ethylenediaminetetraacetic acid, pH 8.0; 1% sodium dodecyl sulfate), and then add clean 0.5mm Glass beads and 25 μL (5mol / L concentration) NaCl solution.

[0048] (5) American SI Vo...

Embodiment 2

[0161] Embodiment 2, xylose metabolism engineering bacterium ZQ5-OE035 can improve the heat resistance of xylose bacterial strain and the growth status on pure xylose plate

[0162] Comparison of growth of ZQ5 empty control strain and xylose metabolism engineered strain ZQ5-OE035 on high temperature plate

[0163] (1) Inoculate the ZQ5 empty control strain and the overexpressed MIG1 strain ZQ5-OE035 in YPD liquid medium (10 g / L yeast extract powder, 20 g / L glucose, 20 g / L peptone) supplemented with G418 100 μg / mL, Cultivate overnight at 30°C, 150rpm.

[0164] (2) As above (same as step (1) in Example 2), 10% volume was transferred to continue the culture, and expanded to 30mLYPD liquid medium to ensure continuous culture and maintain cell viability.

[0165] (3) Measure and use the absorbance value of fresh YPD liquid culture medium at a wavelength of 620nm to be zero, transfer to fresh YPD medium with 10% inoculum size, continue to cultivate for 4h to 5h, and the absorbance ...

Embodiment 3

[0176] Embodiment 3, Shake flask fermentation performance comparison between no-load control strain and xylose metabolism engineering bacteria in mixed sugar and pure xylose

[0177] 1. Comparison of fermentation performance of ZQ5 no-load control strain and xylose metabolism engineered strain ZQ5-OE035 in mixed sugar

[0178] (1) Inoculate the ZQ5 empty control strain and the overexpressed MIG1 strain ZQ5-OE035 in 5 mL of YPD seed medium (10 g / L yeast extract powder, 20 g / L glucose, 20 g / L peptone) supplemented with G418 100 μg / mL Medium, overnight culture, 30°C, 150rpm.

[0179] (2) Same as 1, expanded to 150mLYPD liquid medium.

[0180] (3) Measure and use the absorbance value (OD value) of fresh YPD liquid medium at wavelength 620nm as zero point, transfer to fresh YPD medium with 10% inoculum size respectively, continue to cultivate 6h, make the growth of bacterial strain keep good state.

[0181] (4) Use a sterilized 50mL centrifuge tube, 10000rpm, 5min, to collect th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com