Alloy nano-particle preparation method based on protein reduction method

A technology of alloy nanoparticles and reduction method, which is applied in the direction of nanotechnology, can solve the problems of accelerating reduction and synthesizing alloys or even ternary alloys, and achieves the effects of increasing synthesis rate, good repeatability, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

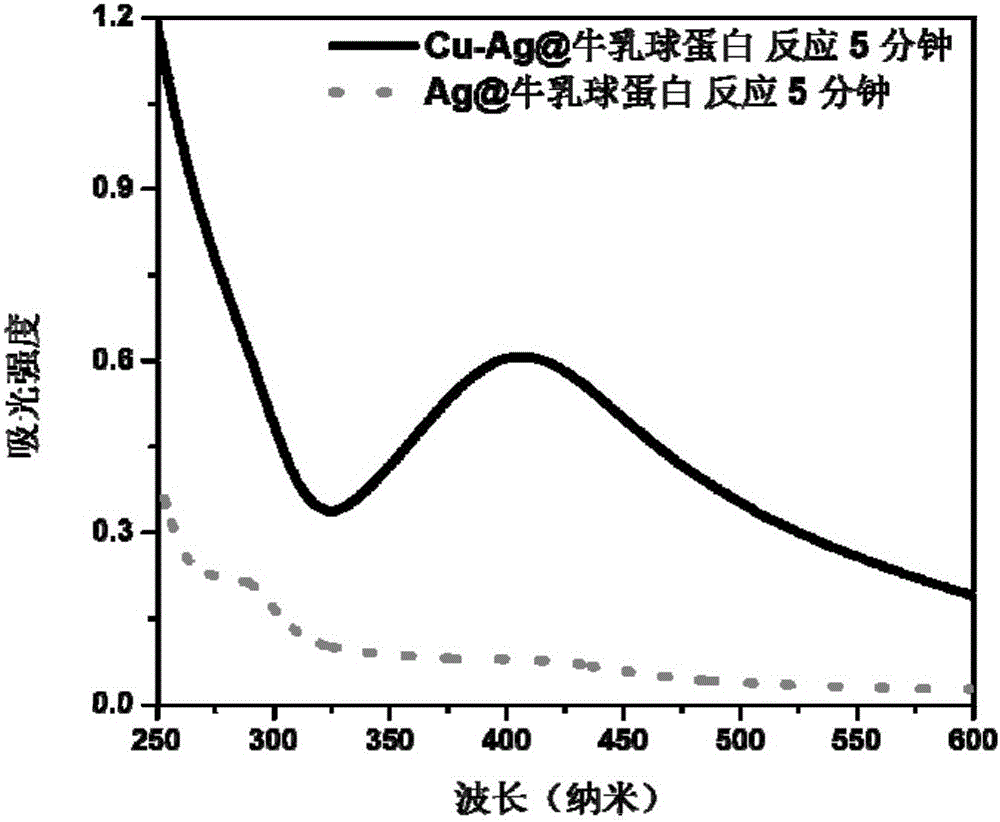

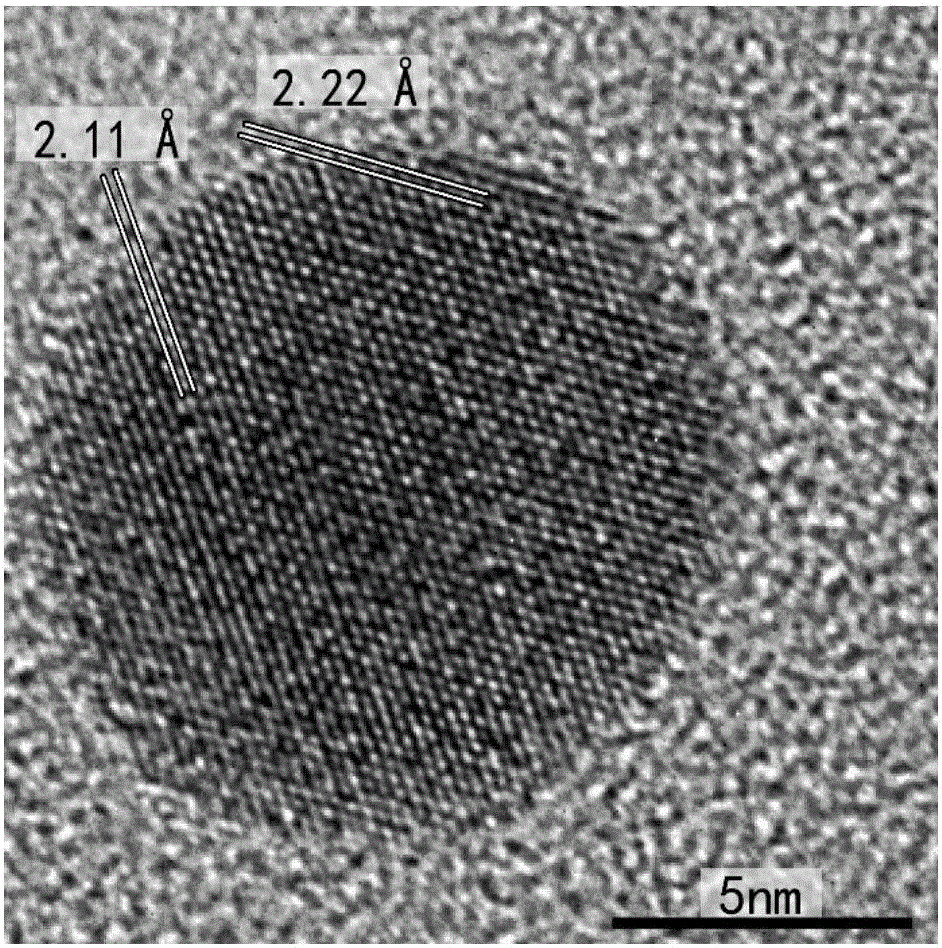

[0030] Embodiment 1: the preparation of bovine lactoglobulin reduced copper-silver alloy nanoparticles, the specific operation steps are as follows:

[0031] (1) Preparation of purified bovine lactoglobulin solution: Weigh a certain amount of bovine lactoglobulin powder and dissolve it in ultrapure water, adjust the pH to 11.0, and centrifuge it after one hour to get the supernatant, and remove it by ultracentrifugation or dialysis Impurity ions in the original protein. Finally, the concentration of the purified bovine lactoglobulin solution was determined to be 4 mg mL by a UV spectrophotometer -1 .

[0032] (2) Noble metal nano-silver uses silver nitrate as a precursor to prepare a 10 mM silver nitrate solution.

[0033] (3) A metal salt with a potential lower than that of the silver redox electrode uses copper sulfate as a precursor to prepare a 20 mM copper sulfate solution.

[0034] (4) Preparation of alloy nano-copper-silver bovine lactoglobulin complex: 500 μL bovine...

Embodiment 2

[0036] Embodiment 2: the preparation of bovine lactoglobulin reduced copper-silver-gold ternary alloy nanoparticles, the specific operation steps are as follows:

[0037] (1) Prepare purified bovine lactoglobulin solution: as described in step (1) in Example 1, the purified bovine lactoglobulin is determined to be 4 mg mL -1 .

[0038] (2) Noble metal nano-gold and silver use chloroauric acid and silver nitrate as precursors to prepare 10mM silver nitrate solution and 20mM chloroauric acid solution.

[0039] (3) A metal salt with a redox electrode potential lower than that of gold and silver was selected as copper chloride as a precursor to prepare a 20 mM copper sulfate solution.

[0040](4) Preparation of alloy nano-copper-silver-golden bovine lactoglobulin complex: put 500 μL bovine lactoglobulin solution, 180 μL copper sulfate solution, 240 μL silver nitrate solution, 100 μL chloroauric acid solution, and 4 mL deionized water into a small glass in the bottle. Adjust the...

Embodiment 3

[0042] Embodiment 3: the preparation of bovine lactoglobulin amyloid fibrils reduced copper-silver alloy nanoparticles, the specific operation steps are as follows:

[0043] (1) Preparation of bovine lactoglobulin amyloid fibrils: as described in step (1) in Example 1, the preparation concentration is 50 mg mL -1 The purified bovine lactoglobulin solution was adjusted to pH 12 and placed in a water bath at 90° C. for 20 hours to obtain a bovine lactoglobulin amyloid fiber solution.

[0044] (2) Noble metal nano-silver uses silver nitrate as a precursor to prepare a 30 mM silver nitrate solution.

[0045] (3) Copper nitrate is used as a precursor for the metal salt with a lower potential than the redox electrode of silver, and a 20 mM copper sulfate solution is prepared.

[0046] (4) Preparation of alloy nano-copper-silver bovine lactoglobulin amyloid fibril complex: put 50 μL bovine lactoglobulin amyloid fibril solution, 180 μL copper sulfate solution, 90 μL silver nitrate so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com