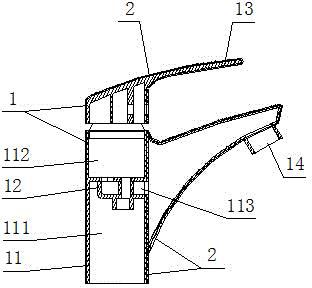

Environment-friendly faucet with ceramic coating and manufacturing method of environment-friendly faucet

A technology of ceramic coating and production method, which is applied in the direction of coating, valve operation/release device, valve details, etc. It can solve the problems of affecting water performance, faucet is easy to cause corrosion, and is highly toxic, so as to achieve strong adhesion, Ceramic coating is bright and ceramic coating is stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] The proportion is calculated according to the weight, and the total weight of this embodiment is 150 copies

[0082] A. Ceramic coating 2 The preparation steps of the material are as follows:

[0083] The component distribution ratio is based on weight

[0084] Ⅰ, base material production

[0085] ⑴ 9.0 parts of porcelain powder, 1.5 quartz powder, 3.0 copies of dioxide (replaced by the quality percentage: 66.7%porcelain powder, 11.1%quartz powder, 22.2%of the dioxide)material;

[0086] 所 Place the step ⑴ mixing in the sintering oven, perform high temperature reactions at 1300 ° C, sintering 1.5h, cooling, and sintering;

[0087] (3) The sintering material obtained from the step is placed in the grinding equipment, crushed and worn into 560 granular mixture;

[0088] 所 所, put the mixing material in the drying equipment, dry it, and get the base material;

[0089] Ⅱ.

[0090] 乙, 107.1 copies of polytetrafluoroethylene dispersion liquid in the mixer, fully stir;

[0091] Ⅲ, a...

Embodiment 2

[0142] The distribution ratio of the component is based on the weight, and the total weight of the embodiment is 500 copies

[0143] A. Ceramic coating 2 The preparation steps of the material are as follows:

[0144] The component distribution ratio is based on weight

[0145] Ⅰ, base material production

[0146] ⑴ 10.0 parts of porcelain powder, 5.0 quartz powder, 10.0 copies of dioxide (replaced by 40%of the quality percentage of porcelain powder, 20%quartz powder, and 40%of the dioxide), mixing in the mixerIt

[0147] 所 Place the step ⑴ mixing in the sintering furnace, perform high temperature reactions at 1350 ° C, sintering 2.0h, cooling, to be sintered;

[0148] (3) The sintering material obtained in step ⑵ is placed in the grinding equipment, crushed and worn into 600 granular mixture;

[0149] 所 所, put the mixing material in the drying equipment, dry it, and get the base material;

[0150] Ⅱ.

[0151] 乙, 421.5 parts of polytetrafluoroethylene dispersion liquid are placed i...

Embodiment 3

[0203] The distribution ratio of the component is based on the weight, and the total weight of this embodiment is 800 copies

[0204] A. Ceramic coating 2 The preparation steps of the material are as follows:

[0205] The component distribution ratio is based on weight

[0206] Ⅰ, base material production

[0207] ⑴In 48.0 parts of porcelain powder, 24.0 copies of quartz powder, 40.0 copies of dioxide (replaced by 42.9%of porcelain powder, 21.4%of quartz powder, 35.7%of the dioxide).It

[0208] 所 Put the step ⑴ Mixing in the sintering oven, perform high temperature reactions at 1250 ° C, sintering 1.0h, cooling, and sintering;

[0209] (3) The sintering material obtained from the step is placed in the grinding equipment, crushed and worn into 520 granular mixture;

[0210] 所 所, put the mixing material in the drying equipment, dry it, and get the base material;

[0211] Ⅱ.

[0212] 乙, 460.8 portion of the polytetrafluoroethylene dispersing solution is placed in the mixer, stirred f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com