Layered perovskite structure material and application in methylamine lead perovskite thin-film solar cell

A perovskite structure, layered technology, applied in the field of solar cells, can solve the problems of water and oxygen sensitivity, poor stability, difficult to control the nucleation and crystallization process of methylamine lead iodine film, achieve uniform morphology and improve blocking ability. , the effect of improving stability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Implementation Example 1: Preparation of methylamine lead iodide perovskite thin-film solar cell device by one-step method.

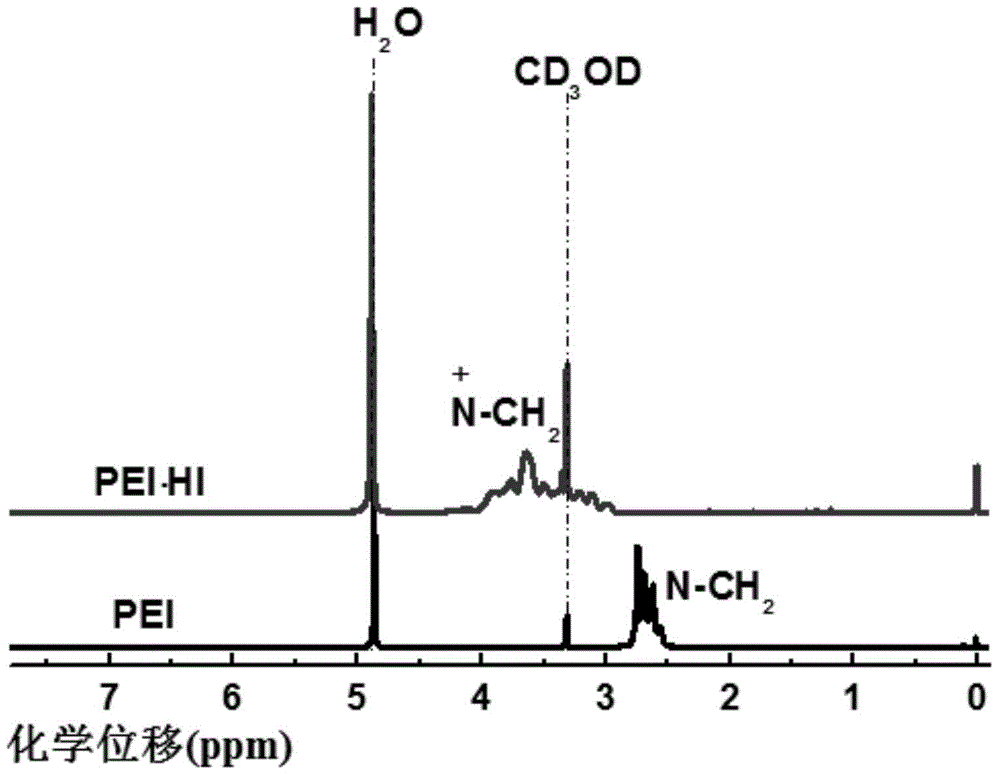

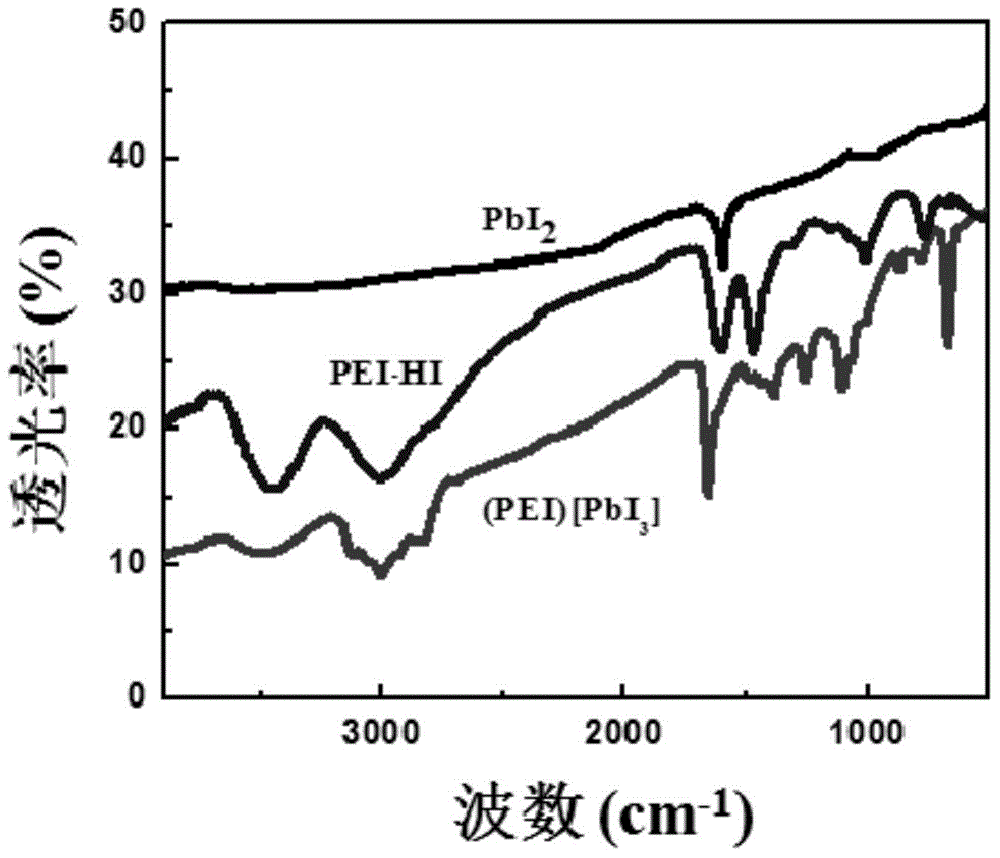

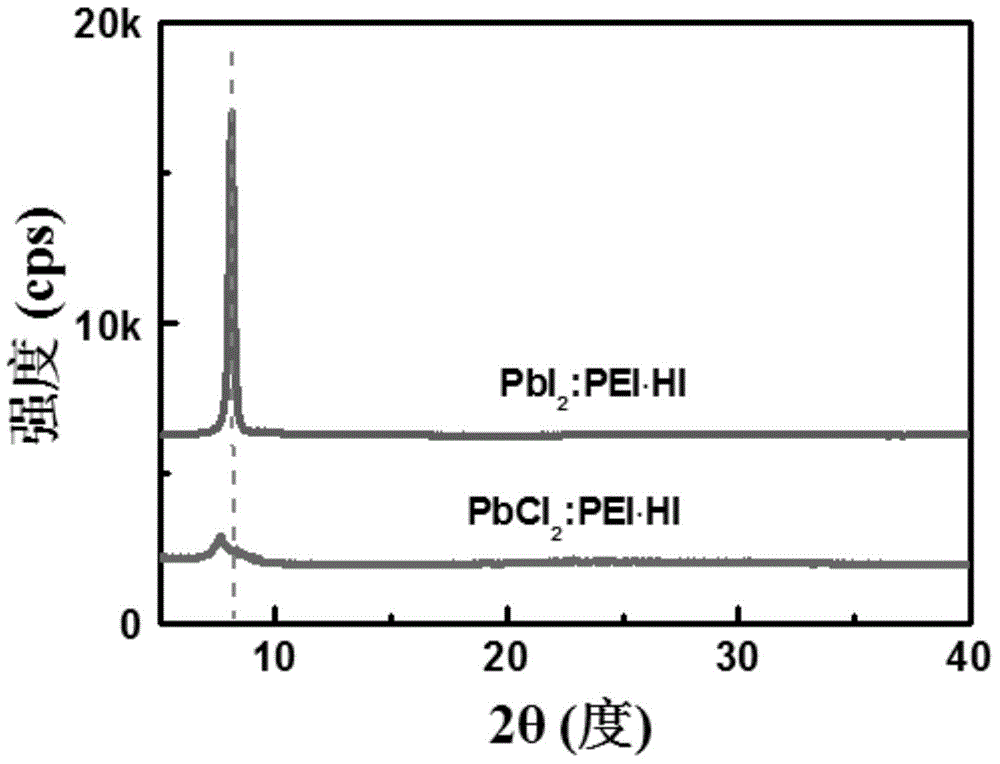

[0049] PbCl 2 , PbI 2 and CH 3 NH 3 I was dissolved in N,N-dimethylformamide (DMF) solution with a total mass fraction of 45% according to a molar ratio of 1:1:4, and stirred at room temperature for 12 hours. Clean the surface of ITO glass. After cleaning the surface with ultraviolet ozone for 10 minutes, spin-coat the conductive polymer PEDOT:PSS on the glass at a speed of 4000rpm, then heat at 140°C for 10min, and then spin-coat the surface of PEDOT:PSS at a speed of 3000rpm PEI·HI (10mg / ml, methanol solution) for modification. Then the perovskite solution was spin-coated at a speed of 4000rpm, and a perovskite film was prepared on the surface. After spin coating, the substrate was placed on a hot stage and heated at 100°C for 60min. PCBM (20 mg / ml, chlorobenzene solution) was spin-coated on the surface of the perovskite film at a speed o...

Embodiment 2

[0051] Implementation Example 2: Preparation of methylamine lead iodine perovskite thin-film solar cell device by two-step method.

[0052] Configure 462mg / ml of PbI respectively 2 / DMF solution and 20mg / ml of CH 3 NH 3 I / isopropanol solution. Clean the surface of ITO glass in the same way. After cleaning the surface with ultraviolet ozone for 10 minutes, spin-coat the conductive polymer PEDOT:PSS on the glass at a speed of 4000rpm, then heat at 140°C for 10min, and spin-coat PEI on the surface of PEDOT:PSS at a speed of 3000rpm. HI (10 mg / ml, methanol solution) was used for modification. Then PbI 2 The solution was spin-coated at 4000 rpm, followed by spin-coating CH 3 NH 3 I solution. After spin coating, the substrate was placed on a hot stage and heated at 100°C for 10 min. PCBM (20 mg / ml, chlorobenzene solution) was spin-coated on the surface of the perovskite film at a speed of 1500 rpm. Finally, under high vacuum conditions, Ag electrodes are vapor-deposited to ...

Embodiment 3

[0054] Implementation Example 3: Preparation of methylamine-lead-iodide perovskite thin-film solar cell device.

[0055] PbCl 2 , PbI 2 and CH 3 NH 3 I was dissolved in N,N-dimethylformamide (DMF) solution with a total mass fraction of 45% according to a molar ratio of 1:1:4, and stirred at room temperature for 12 hours. Clean the surface of ITO glass. After cleaning the surface with ultraviolet ozone for 10 minutes, spin-coat the conductive polymer PEDOT:PSS on the glass at a speed of 4000rpm, then heat at 140°C for 10min, and then spin-coat the surface of PEDOT:PSS at a speed of 3000rpm PTN·HI (10mg / ml, isopropanol solution) for modification. Then the perovskite solution was spin-coated at a speed of 4000rpm, and a perovskite film was prepared on the surface. After spin coating, the substrate was placed on a hot stage and heated at 100°C for 60min. PCBM (20 mg / ml, chlorobenzene solution) was spin-coated on the surface of the perovskite film at a speed of 1500 rpm. Fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com