Method for treating nickel/cobalt-contained multi-metal alloyed scrap

A processing method and multi-metal technology, applied in the field of metallurgy and chemical industry, can solve the problems of high safety and environmental protection risks, unsatisfactory recovery rate of valence metals, harsh leaching conditions, etc., and achieve high furnace body use efficiency, significant environmental protection advantages, and efficient utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

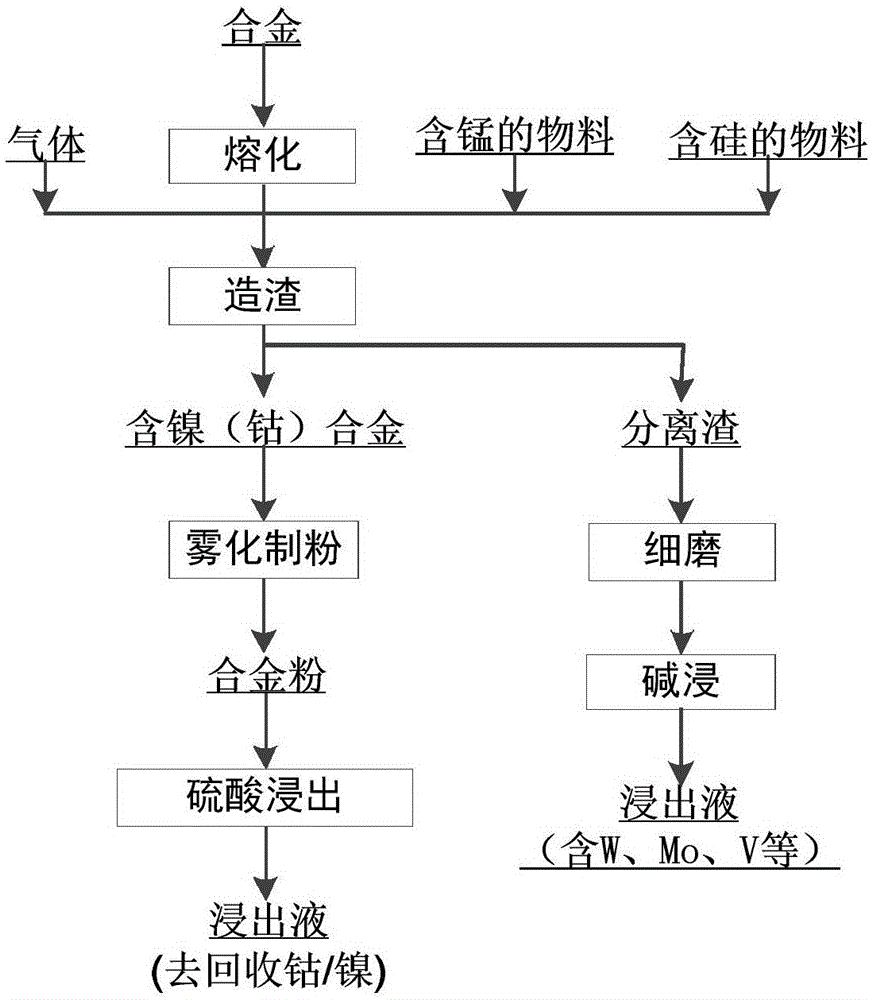

[0033] a kind of like figure 1 The processing method of the multi-metal alloy waste material containing nickel / cobalt of the present invention shown, may further comprise the steps:

[0034] (1) Melting the multi-metal alloy: the multi-metal alloy waste in this embodiment comes from the waste catalyst pyrometallurgy, and its alloy composition is Ni 19.12%, Co 2.50%, Fe 58.10%, Mo 8.72%, W 1.08%, V 2.30%; A 50kg-level medium-frequency induction furnace was used to carry out the blowing slagging test, the amount of multi-metal alloy waste added was 35kg, and the melting temperature was 1500°C;

[0035] (2) Add manganese-containing material and silicon-containing material, the manganese-containing material in the present embodiment adopts metal manganese (Mn content 99%), and one-time addition is 5.0kg, and silicon-containing material adopts silica (SiO 2 Content 98%), one-time addition 9.32kg; at the same time, air is introduced into the interior and surface of the alloy melt f...

Embodiment 2

[0041] a kind of like figure 1 The processing method of the multi-metal alloy waste material containing nickel / cobalt of the present invention shown, may further comprise the steps:

[0042] (1) Melting the multi-metal alloy scrap: The multi-metal alloy scrap in this embodiment comes from waste superalloy, and its alloy composition is Ni 62.72%, Co 8.54%, Fe 0.64%, Mo 1.65%, W 7.64%, Al 5.87 %, Re 2.42%, Nb 0.51%, Cr 4.77%; 1000kg intermediate frequency induction furnace is used for blowing and slagging, the amount of multi-metal alloy waste added is 700kg, and the melting temperature is 1700°C;

[0043] (2) Add manganese-containing material and silicon-containing material, the manganese-containing material in the present embodiment adopts pyrolusite (Mn content 39.86%, SiO 2 13.33%), the one-time addition is 40kg, and the silicon-containing material adopts silica (SiO 2 content 98%), the amount of one addition is 30.15kg; at the same time, a mixed gas of air and oxygen is i...

Embodiment 3

[0050] a kind of like figure 1 The processing method of the multi-metal alloy waste material containing nickel / cobalt of the present invention shown, may further comprise the steps:

[0051] (1) Melting the multi-metal alloy waste material: the multi-metal alloy waste material composition of the present embodiment is Ni 65.80%, Co 6.72%, Mo 1.65%, W 9.00%, Al 6.53%, Re 2.23%, Ta 4.10%; Adopt 1000kg The slag is blown and slag-made in a medium-frequency induction furnace, the amount of multi-metal alloy waste added is 700kg, and the melting temperature is 1700°C;

[0052] (2) Add manganese-containing material and silicon-containing material, the manganese-containing material in the present embodiment adopts metal manganese (Mn content 99%) and manganese dioxide powder (MnO 2 content 95%) mixture (the mass ratio of the two is 3:7), the amount of one addition is 30kg, and the silicon-containing material adopts a mixture of manganese-silicon alloy (Mn 68%, Si 18%) and silica (SiO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com