Preparation method for metal oxide/platinum nanoparticle composite catalyst

A platinum nanoparticle and composite catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problem of unstable properties of platinum nanoparticles, and achieve Improve cold start performance, reduce operating costs, and enhance the effect of low temperature activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

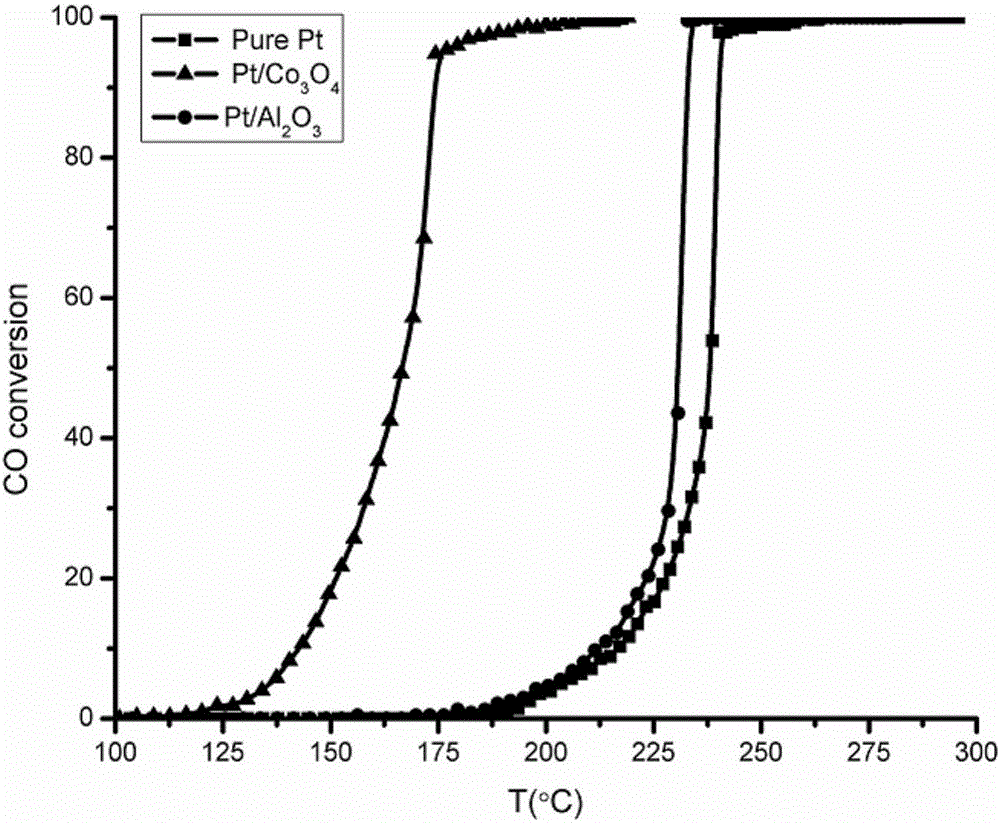

[0025] Example 1Pt / Co 3 o 4 Preparation of substrate-type catalyst

[0026] (1) The silicon wafer was boiled for 20 minutes in a mixed solution of deionized water, ammonia water, and hydrogen peroxide at a volume ratio of 5:1:1, and then the silicon wafer was dried with high-purity nitrogen gas.

[0027] (2) Put the silicon wafer treated in (1) into the atomic layer deposition equipment; use cobaltocene and ozone to grow cobalt oxide on the surface of the silicon wafer. Pass high-purity oxygen (99.999%) into the ozone generator to generate ozone with a volume concentration of about 11%). The cobalt precursor temperature was maintained at 100 °C during the deposition process. The reaction temperature was 150°C. The carrier gas is still high-purity nitrogen, the cobalt precursor pulse time is 1.6s, the ozone precursor pulse time is 2s, and the nitrogen purge time is 8s. Repeat 25 cycles to form a thin film of cobalt tetraoxide on the silicon wafer.

[0028] (3) put the sam...

Embodiment 2

[0029] Example 2Pt / Al 2 o 3 Preparation of substrate-type catalyst

[0030] Repeat Example 1 with the same steps as described, the difference is that the organometallic salt used in step (2) is trimethylaluminum, and the oxidizing agent is deionized water. The reaction temperature is 180°C, the carrier gas is nitrogen, the precursor pulse time of the two precursors is 0.1s, the nitrogen cleaning time is 8s, and the number of deposition cycles is 9 times to obtain Pt / Al 2 o 3 Substrate-type catalyst, which can be used to catalyze the oxidation reaction of methanol or CO.

Embodiment 3

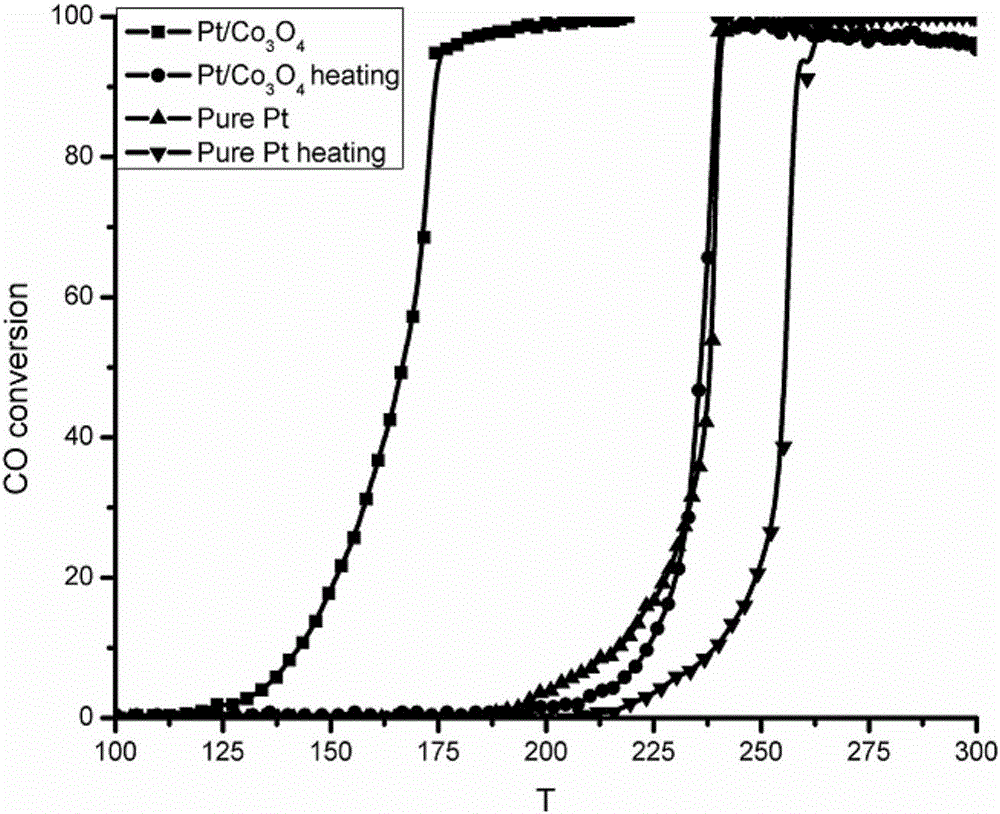

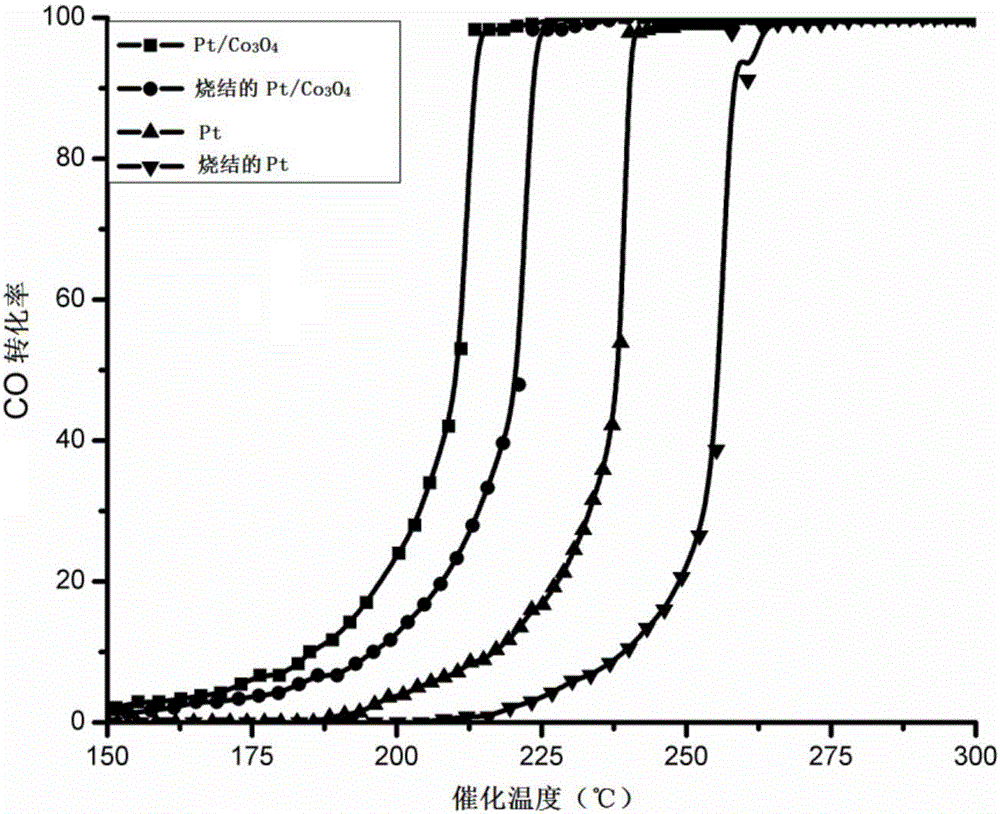

[0034] Example 3Pt / Co 3 o 4 Preparation of coated catalyst

[0035] In the comparative example, the silicon wafer with the Pt nanocatalyst grown on the surface was placed in an atomic layer deposition device; cobalt oxide was grown on the surface of the platinum nanoparticle using cobaltocene and ozone. Pass high-purity oxygen (99.999%) into the ozone generator to generate ozone with a volume concentration of about 11%). The cobalt precursor temperature was maintained at 100 °C during the deposition process. The reaction temperature was 150°C. The carrier gas is still high-purity nitrogen, the cobalt precursor pulse time is 1.6s, the ozone precursor pulse time is 2s, and the nitrogen purge time is 8s. Repeat 25 cycles to form a thin film of cobalt tetroxide on the platinum nanoparticles to obtain the required Pt / Co 3 o 4 Coated catalyst can be used to catalyze the oxidation reaction of CO.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com