Heteroatom-doped graphene material with holes on the surface and its preparation, application and device

A heteroatom and graphene technology, applied in the field of electrochemistry, can solve the problems of easy aggregation of graphene sheets, high battery cost, and harsh operating conditions, so as to reduce van der Waals interaction, improve electrocatalytic performance, and reduce reaction temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A preparation method of heteroatom-doped surface hole graphene material, specifically comprising the following steps:

[0043] (1) Synthesis of graphene oxide

[0044] Adopt improved Hummers method to prepare graphene oxide, its technological process is as follows:

[0045] (1-1) Assemble the reaction flask in an ice-water bath, add a solid mixture of 1g of expanded graphite powder and 2.5g of sodium nitrate to the reaction flask under stirring (the stirring speed is 500r / min), and then add 150mL of mass percentage 95% concentrated sulfuric acid, reacted in an ice-water bath for 30 minutes; then, added 15 g of potassium permanganate 60 times (1 min each time), controlled the reaction temperature at 0 ° C, and continued to react for 12 h; then added 150 mL of deionized water to dilute After stirring and reacting for 30 minutes (the rotating speed of stirring is 500r / min), the temperature was raised to 98° C. at a heating rate of 10° C. / min, and the heat preservation rea...

Embodiment 2

[0054] A nitrogen-doped surface with hole graphene material, the specific preparation method is: (comparative example related to the present invention, high temperature direct pyrolysis reduction method preparation)

[0055] (1) synthesis of graphene oxide: same as embodiment 1;

[0056] (2) synthesis of graphene oxide with holes on the surface: same as Example 1;

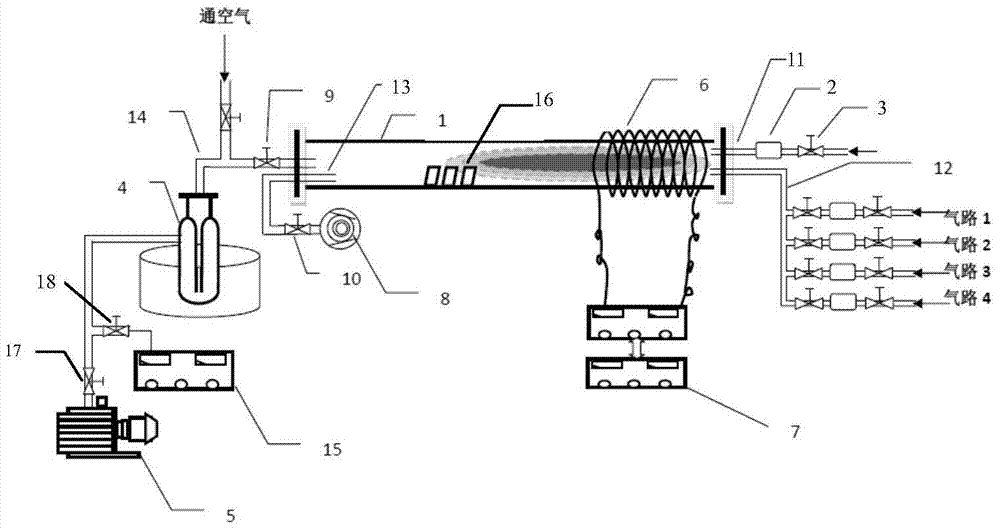

[0057] (3) 20 mg of graphene oxide with holes on the surface is placed in the center of the plasma high-temperature tubular reactor, and then a protective gas N is introduced at one end. 2 and gaseous heteroatom doping source NH 3 (N 2 with NH 3 The volume ratio of the plasma high temperature tubular reactor is 0.5:1), and the plasma high temperature tubular reactor is heated to 850°C at a heating rate of 5°C / min. 3 , after cooling to room temperature, the nitrogen-doped graphene material with holes on the surface prepared by the high-temperature direct pyrolysis reduction method is obtained.

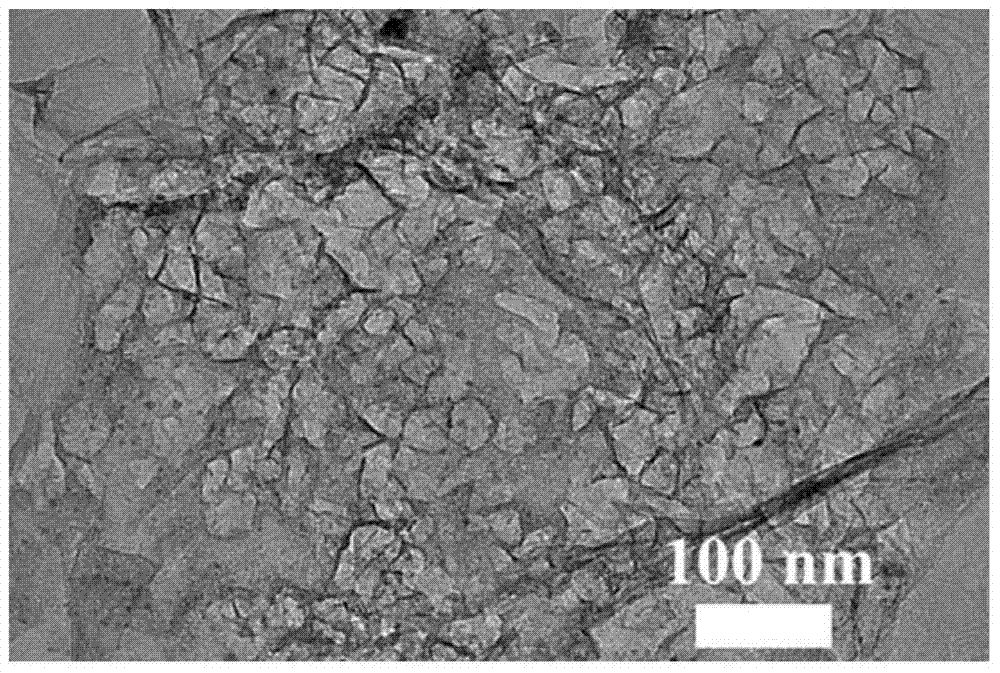

[0058] The nitr...

Embodiment 3

[0060] A heteroatom doped surface graphene material with holes, the specific preparation method is:

[0061] (1) synthesis of graphene oxide: same as embodiment 1;

[0062] (2) synthesis of graphene oxide with holes on the surface: same as embodiment 1;

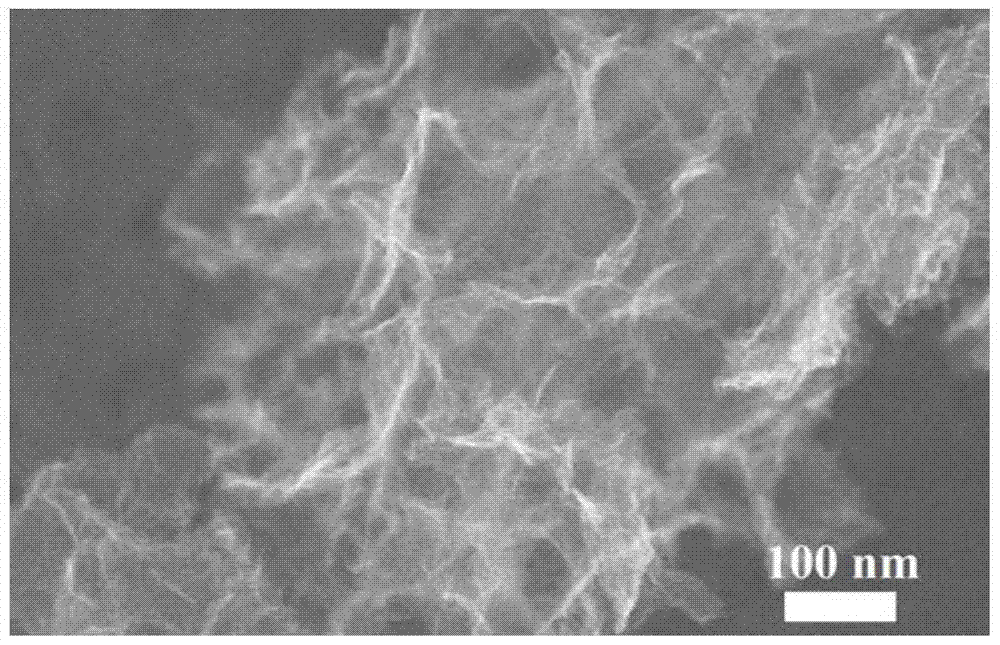

[0063] (3) Place 20 mg of graphene oxide with holes on the surface prepared above in the center of the plasma high-temperature tubular reactor, use a mechanical pump to vacuumize to remove impurities and water vapor, and reduce the pressure to 0.1Pa, and then use a molecular pump to pump Vacuum to 1×10 -4 Pa, then pass protective gas N at one end 2 and gaseous heteroatom doping source diborane to a pressure of 10Pa (the volume ratio of nitrogen to diborane is 0.5:1), heat the plasma high-temperature tubular reactor to 500°C at a heating rate of 10°C / min, and then open RF power supply, under the condition of RF power of 600W, perform plasma discharge for 60min, then turn off the RF and heating power supply, stop feeding dib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com