A kind of polymer iron (iii) chelating agent based on 3-hydroxyl-4-pyridone compound and preparation method thereof

A technology of pyridone and compound, which is applied in the field of polymer materials, can solve the problems of cumbersome synthesis steps, small iron (III) chelation capacity, insolubility and infusibility, etc., and achieve the effect of simple process, convenient industrial production and convenient purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

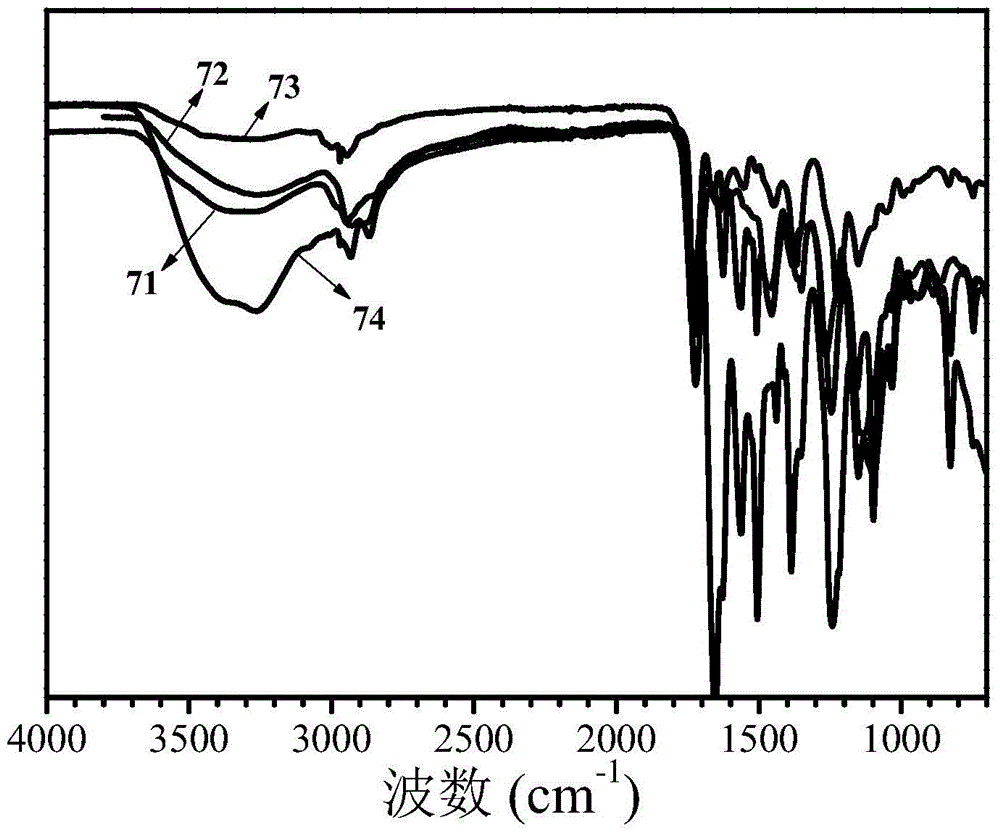

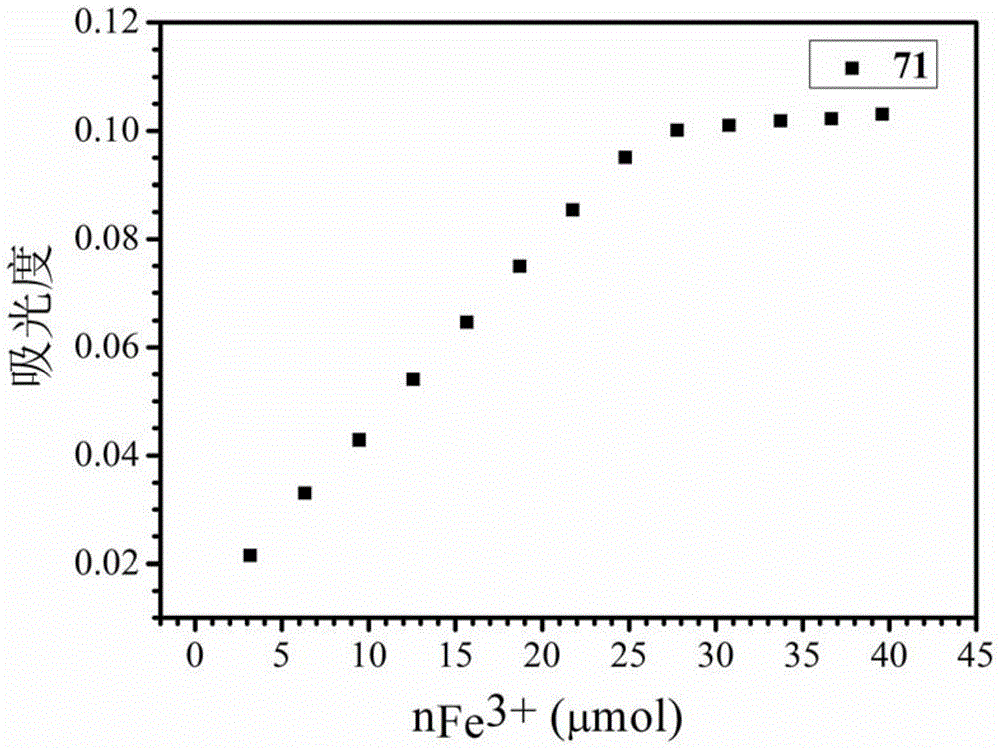

[0038] The preparation process of polymer iron (III) chelating agent in the present embodiment is as follows:

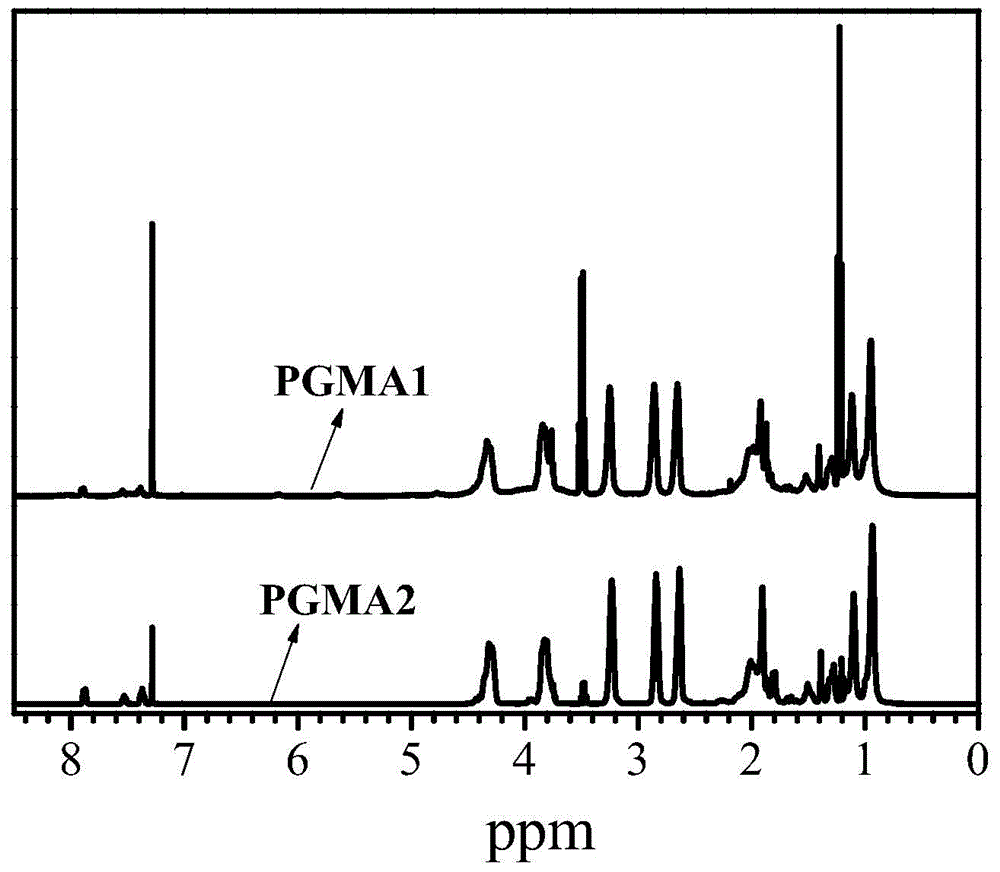

[0039] 1. Free radical polymerization

[0040] Add 1.292g of glycidyl ether methacrylate, 29.965mg of 2-cyano-2-propylbenzodisulfide and 6.916mg of azobisisobutyronitrile into a 25mL single-necked bottle, and then add 1.2mL of anhydrous toluene as Solvent, after removing oxygen (the process of removing oxygen is to first cool the one-mouth bottle in liquid nitrogen for 5-10 minutes, take it out from the liquid nitrogen and use an oil pump to evacuate it for 1-2 minutes, then pass in nitrogen protection, repeat the above operation three times ) in a nitrogen atmosphere at 62°C for 6 hours, add 10 times the volume of anhydrous toluene in cold ether (-20°C, use dry ice for 20min) to settle, centrifuge (4000 rpm) and filter and dry to remove unreacted formazan glycidyl ether acrylate monomer; then add an equal volume of N,N-dimethylformamide to dissolve the polymer, add...

Embodiment 2

[0048] The preparation process of polymer iron (III) chelating agent in the present embodiment is as follows:

[0049] 1. Free radical polymerization

[0050] 0.932g glycidyl ether methacrylate, 18×10 -2 g 2-cyano-2-propylbenzodisulfide and 42.53mg of azobisisobutyronitrile were added to a 25mL single-necked bottle, then 0.87mL of anhydrous toluene was added as a solvent, and after removing oxygen (the process of removing oxygen was first Cool the one-necked bottle in liquid nitrogen for 5-10 minutes, take it out from the liquid nitrogen and vacuumize it with an oil pump for 1-2 minutes, then pass through nitrogen protection, repeat the above operation three times) react at 62°C for 3 hours in a nitrogen atmosphere, Add 10 times the volume of anhydrous toluene in cold ether (-20°C, use dry ice for 20 minutes) to settle, centrifuge (4000 rpm) and filter and dry to remove unreacted glycidyl ether methacrylate monomer; Dissolve the polymer in N,N-dimethylformamide equal to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com