A modified soybean protein hollow capsule material and its preparation method

A soy protein and hollow capsule technology, applied in the direction of capsule delivery, inactive components of polymer compounds, etc., can solve problems such as hardening and brittleness, drug moisture absorption failure, hindering drug release, etc., and achieve good film-forming performance and application potential. Huge, well-adapted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

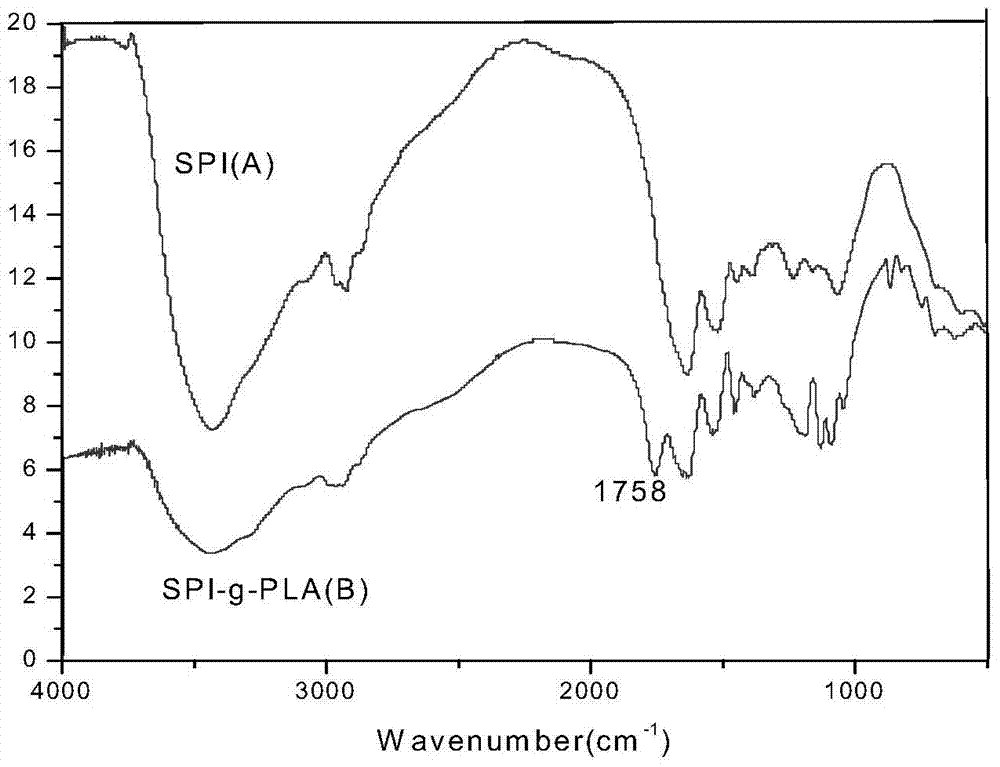

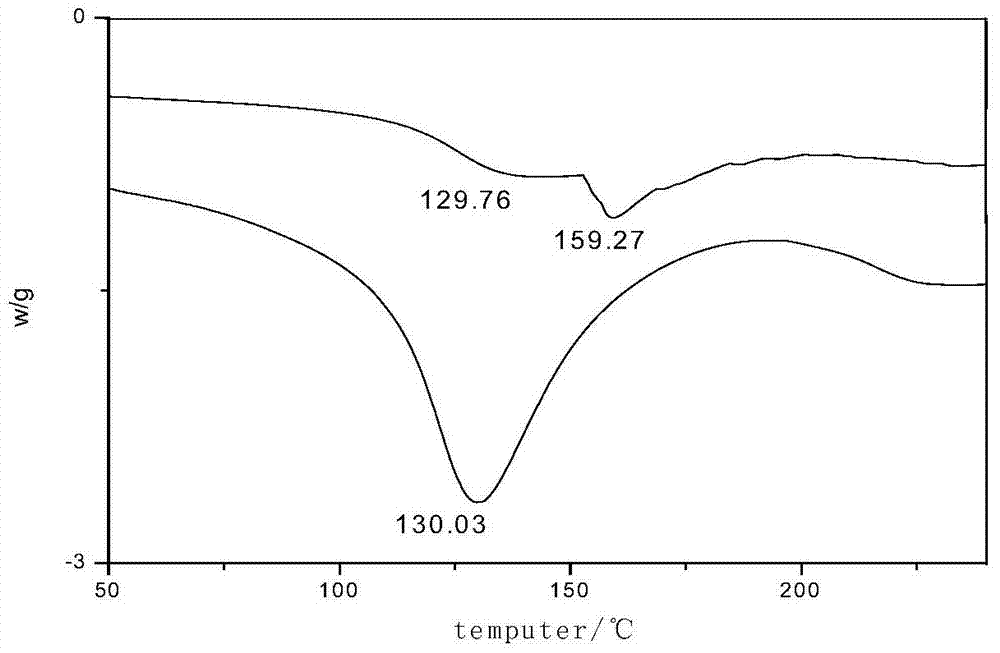

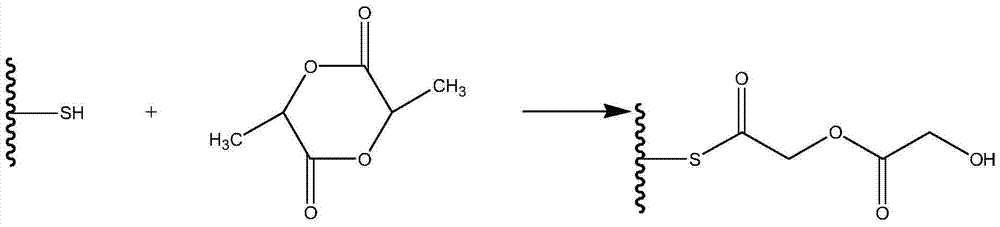

[0033] 1) Mix and dissolve soy protein isolate powder and distilled water at a ratio of 1:5, stir in a water bath at 60°C for 30 minutes under nitrogen protection, then raise the temperature to 70°C, react at constant temperature for 1.5 hours, and use 1.0mol / L sodium hydroxide The solution is adjusted to pH7, and the soybean protein isolate activation treatment is carried out;

[0034] 2) After the activation treatment, add the lactic acid prepolymer produced by the reaction, raise the temperature to 80°C, add the catalyst after the temperature is stable, evacuate to 100Pa, and react for 4 to 12 hours to form a water-insoluble copolymer product, remove the product, and wash repeatedly , and vacuum-dried to complete the graft modification of soybean protein isolate.

[0035] 3) each component and mass ratio:

[0036] Modified soybean protein: 85 parts;

[0037] κ-type carrageenan: 10 parts;

[0038] Polyethylene glycol: 2.0 parts;

[0039] Genipin: 2.0 parts;

[0040] Tea g...

Embodiment 3-5

[0046] 1) Soybean protein isolate powder and distilled water were mixed and dissolved at a ratio of 1:3, and stirred in a water bath at 60°C for 30 minutes under nitrogen protection. Then raise the temperature to 70°C, react at constant temperature for 2 hours, adjust the pH to 8 with 1.0mol / L sodium hydroxide solution, and perform the activation treatment of soybean protein isolate;

[0047] 2) After the activation treatment, add the lactic acid prepolymer produced by the reaction, raise the temperature to 80°C, add the catalyst after the temperature is stable, evacuate to 100Pa, and react for 4 to 12 hours to form a water-insoluble copolymer product, remove the product, and wash repeatedly , vacuum-dried to complete the graft modification of soybean protein isolate;

[0048] 3) each component and mass ratio:

[0049] Modified soybean protein: 65 parts;

[0050] Pectin and sodium alginate: 32 parts;

[0051] Sucrose vinegar: 1.0 parts;

[0052] Genipin: 1.0 parts;

[005...

Embodiment 6-8

[0056] 1) Mix and dissolve soybean protein isolate powder and distilled water at a ratio of 1:7, and stir for 30 minutes in a water bath at 60°C under nitrogen protection. Then raise the temperature to 90°C, react at constant temperature for 1.5h, adjust the pH to 8 with 1.0mol / L sodium hydroxide solution, and carry out the activation treatment of soybean protein isolate;

[0057] 2) After the activation treatment, add the lactic acid prepolymer produced by the reaction, raise the temperature to 80°C, add the catalyst after the temperature is stable, evacuate to 100Pa, and react for 4 to 12 hours to form a water-insoluble copolymer product, remove the product, and wash repeatedly , vacuum-dried to complete the graft modification of soybean protein isolate;

[0058] 3) each component and mass ratio:

[0059] Modified soybean protein: 70 parts;

[0060] Pectin and kappa carrageenan: 27 parts;

[0061] Polyethylene glycol: 1.0 parts;

[0062] Transglutaminase: 1.0 parts;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com