Preparation method of one-dimensional SiO<2>: Eu<3+> fiber luminescent material with dimension controllable

A technology of luminescent materials and fibers, applied in the directions of luminescent materials, chemical characteristics of fibers, chemical instruments and methods, etc., can solve the problems of long preparation period, difficult morphology control, poor reproducibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Mix 1.5gTEOS, 2mL ethanol, 3mL acetic acid, and 2mL water evenly, and stir for 30min.

[0025] (2) Add 2.0g of PVP and stir for more than 1 hour to completely dissolve the PVP.

[0026] (3) Let the above solution stand still so that there are no air bubbles in the solution. This is the electrospinning solution. Measure 2 mL with a syringe for later use.

[0027] (4) Turn on the electrospinning machine and adjust various parameters. The flow rate is 0.2mm / min, the receiving distance is 20cm, and the voltage is 20KV (cathode voltage-4KV, anode voltage 16KV).

[0028] (5) Turn on the voltage, connect one end to the receiver aluminum foil (cathode) and the other end to the needle (anode) of the syringe used for electrospinning to perform electrospinning.

[0029] (6) After spinning, the sample is placed in a muffle furnace and calcined at 600°C for 2 hours to obtain undoped rare earth SiO 2 fiber.

Embodiment 2

[0031] Except for the situation described below, the rest are the same as in Example 1, and 2mLH 2 O was replaced by adding 1.15mLH 2 O and 0.85mLEu(NO 3 ) 3 (1M) solution.

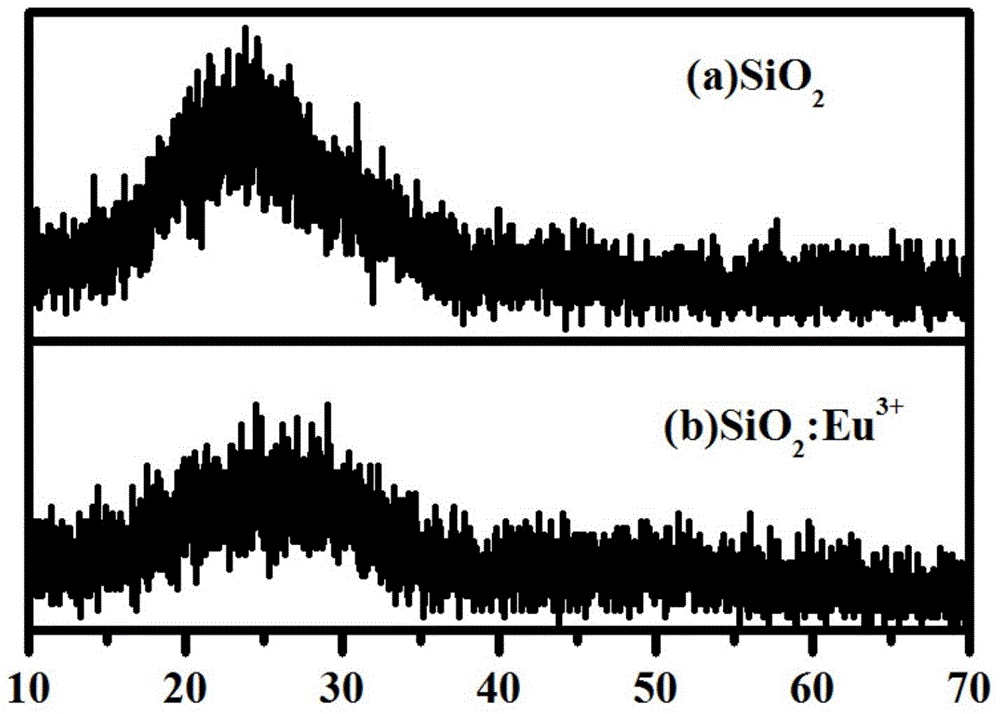

[0032] figure 1 The SiO prepared when the amount of europium nitrate is 0mL and 0.85mL is given in 2 XRD comparison chart of fibers. From the figure, we found that the addition of europium ions did not change the crystal form of the fiber, but still showed the characteristic peaks of amorphous silica, and the intensity decreased after doping, indicating that Eu 3+ Successful doping into the silica matrix reduces the symmetry of the three-dimensional network structure of silica.

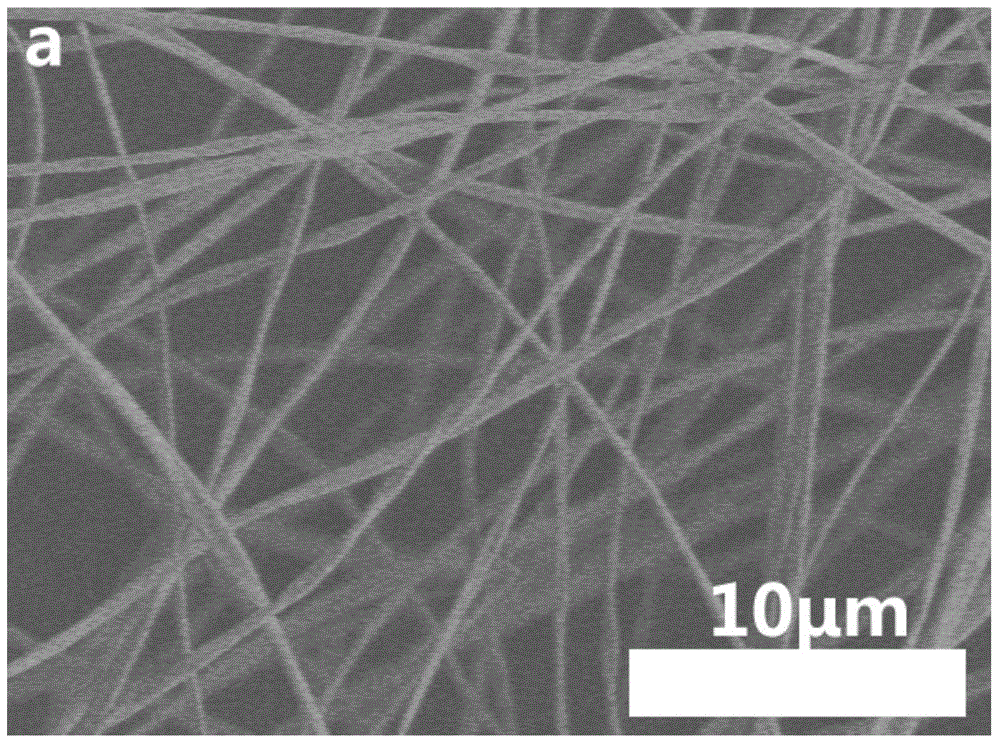

[0033] figure 2 SiO obtained when the volume V (water + europium nitrate) given in (a) is 2.0 mL 2 : Eu 3+ SEM of the fiber, it can be found from the figure that the prepared SiO 2 :Eu 3+ The shape of the fiber is uniform, and the diameter is about 510nm.

Embodiment 3

[0035] Except for the situation described below, the rest are the same as in Example 1, and 2mLH 2 O was replaced by adding 0.65mLH 2 O and 0.85mLEu(NO 3 ) 3 (1mol / L) solution.

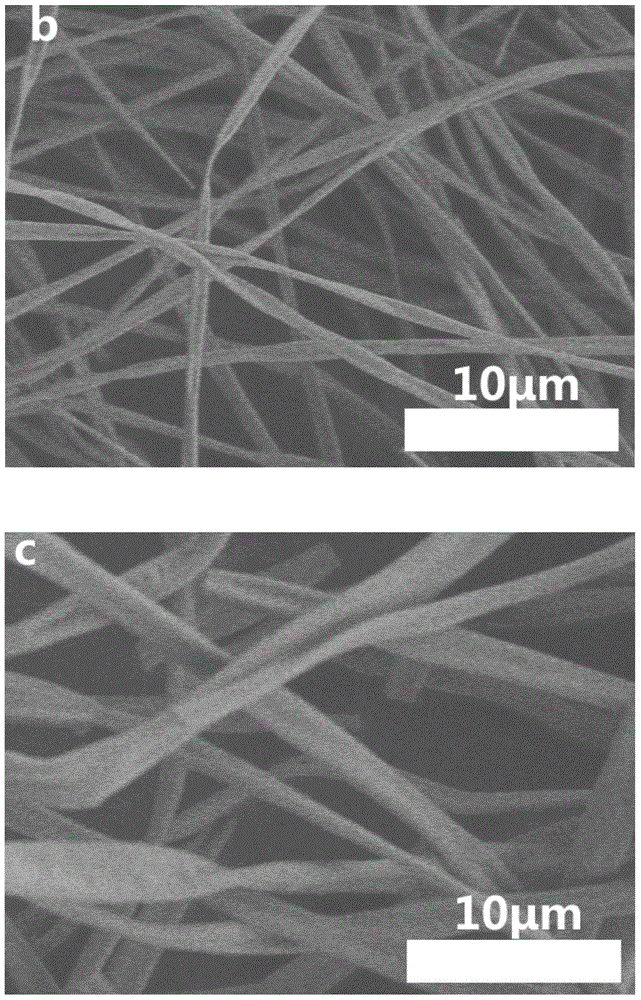

[0036] figure 2 The SiO obtained when the volume V (water + europium nitrate) is 1.5 mL is given in (b). 2 : Eu 3+ SEM of the fiber, it can be found from the figure that the prepared SiO 2 : Eu 3+ The morphology of the fibers is uniform, and the diameter is about 917nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com